Red-clay reinforced polyethylene wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite material and red clay, which is applied in the field of red clay reinforced polyethylene wood-plastic composite material and its preparation, can solve the problems of flammability and achieve the effect of optimizing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

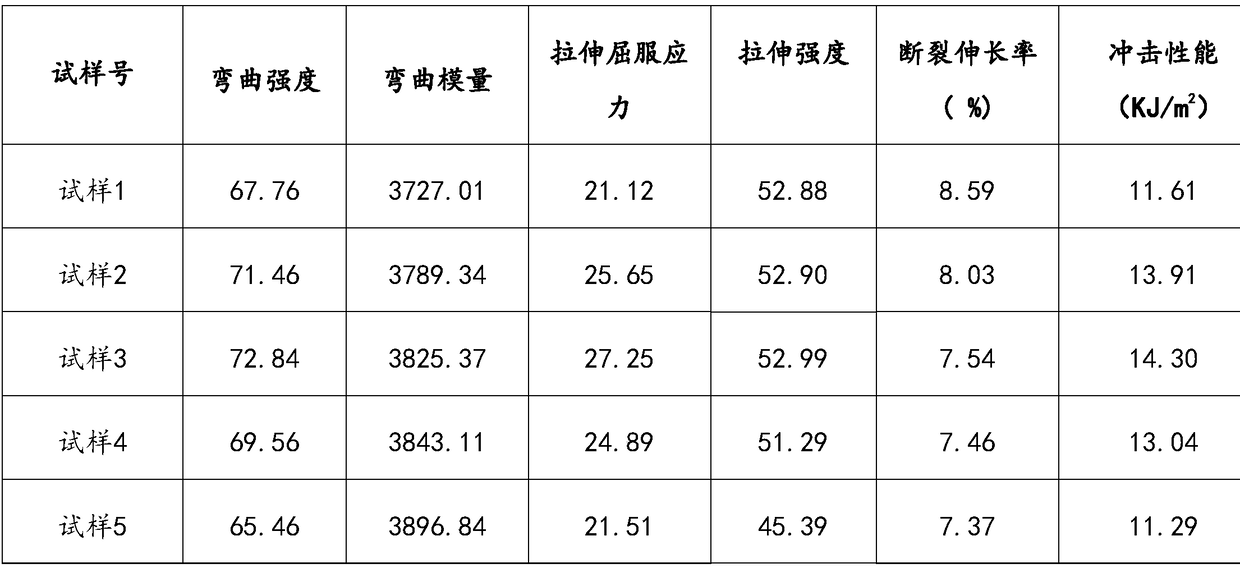

Examples

preparation example Construction

[0035]According to the second aspect of the present invention, there is provided a method for preparing the above-mentioned red clay-reinforced polyethylene wood-plastic composite material, comprising: mixing red clay, wood fiber, polyethylene, coupling agent and lubricant to prepare The mixture is extruded and granulated to obtain raw material particles, and the raw material particles are made into red clay-reinforced wood-plastic composite materials through extrusion molding, injection molding or compression molding.

[0036] Further, extrusion granulation is: extruding and granulating the raw material particles in a twin-screw extruder;

[0037] Further, the temperature of the twin-screw extruder is set to 150-170°C in zone 1, 155-175°C in zone 2, 160-180°C in zone 3, 160-180°C in zone 4, 175-195°C in zone 5, and 160°C in zone 6. -180°C, zone 7 155-175°C;

[0038] Furthermore, the temperature of the twin-screw extruder is set to 155-165°C in zone 1, 160-170°C in zone 2, 16...

Embodiment 1

[0046] Red clay is prepared according to the ratio of 0.5 parts of MgO content, 15 parts of Al2O3 content, 60 parts of SiO2 content, 2 parts of K2O content, 2 parts of CaO content and 7 parts of Fe2O3 content. After soaking for 24 hours, put the red clay in a vacuum mud mixer for refining to make it reach the proper toughness, and refine it 8 times. After the refining is completed, the red clay is soaked in water for a week, and finally the refined red clay is dried to a moisture content of 3%, then milled, screened with an 80-mesh sieve, and sealed for later use. The poplar wood board is crushed, screened with a 40-mesh sieve, and dried at 90°C until its moisture content is 3% to prepare wood fiber. The above-mentioned red coat clay accounted for 0%, wood fiber accounted for 54%, polyethylene accounted for 42%, coupling agent accounted for 3%, and lubricant accounted for 1% ratio to mix and prepare a mixture, and the mixture was placed Extruded and granulated by twin-screw e...

Embodiment 2

[0048] The red clay is prepared according to the ratio of 1.5 parts of MgO content, 16 parts of Al2O3 content, 62 parts of SiO2 content, 2.5 parts of K2O content, 2.2 parts of CaO content, and 7.5 parts of Fe2O3 content. After soaking for 24 hours, put the red clay in a vacuum mud mixer for refining to make it reach the proper toughness, and refine it 8 times. After refining, the red clay is soaked in water for a week, and finally the refined red clay is dried to a moisture content of 2.5%, then milled, sieved with an 80-mesh sieve, and sealed for later use. Poplar wood boards are crushed, screened with a 45-mesh sieve, and dried at 95° C. until their moisture content is 4% to prepare wood fibers. The above-mentioned red clay clay accounts for 3%, wood fiber accounts for 56%, polyethylene accounts for 40%, coupling agent accounts for 4%, and lubricant accounts for 0% ratio to mix and prepare the mixture, and the mixture is placed Extruded and granulated by twin-screw extruder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com