Preparation method of high-yield flower-fragrant and fruit-fragrant oil fermented bean curds

A floral and fruity aroma technology, applied in the field of bean product fermentation, can solve the problems of serious bacterial contamination and unstable product aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: The strain isolation and identification method of Mucor racemosus CGMCC No.15264

[0024] (1) Obtain a suitable dilution gradient and culture

[0025] Weigh 25g of naturally fermented fermented bean curd in Mouding, Chuxiong Prefecture, Yunnan Province, add it into a homogeneous bag filled with 225mL of sterile water, and beat it with a slap-type homogenizer for 2min; In sterile water, dilute the homogeneous sample solution (liquid samples can include stock solution) by 10 times, so that the concentration of the sample is gradually diluted to 10 -5 , take 4 dilutions of 10 2 ~10 5 Pipette 1mL sample homogeneous solution into 2 sterile petri dishes for each dilution respectively, pour 20mL potato-glucose-agar medium cooled to 46°C into the petri dish in time, and Rotate the petri dish to mix evenly. After the agar solidifies, turn the petri dish upside down and incubate at 28°C±1°C for 5 days.

[0026] (2) Separation and purification

[0027] Use the dot ...

Embodiment 2

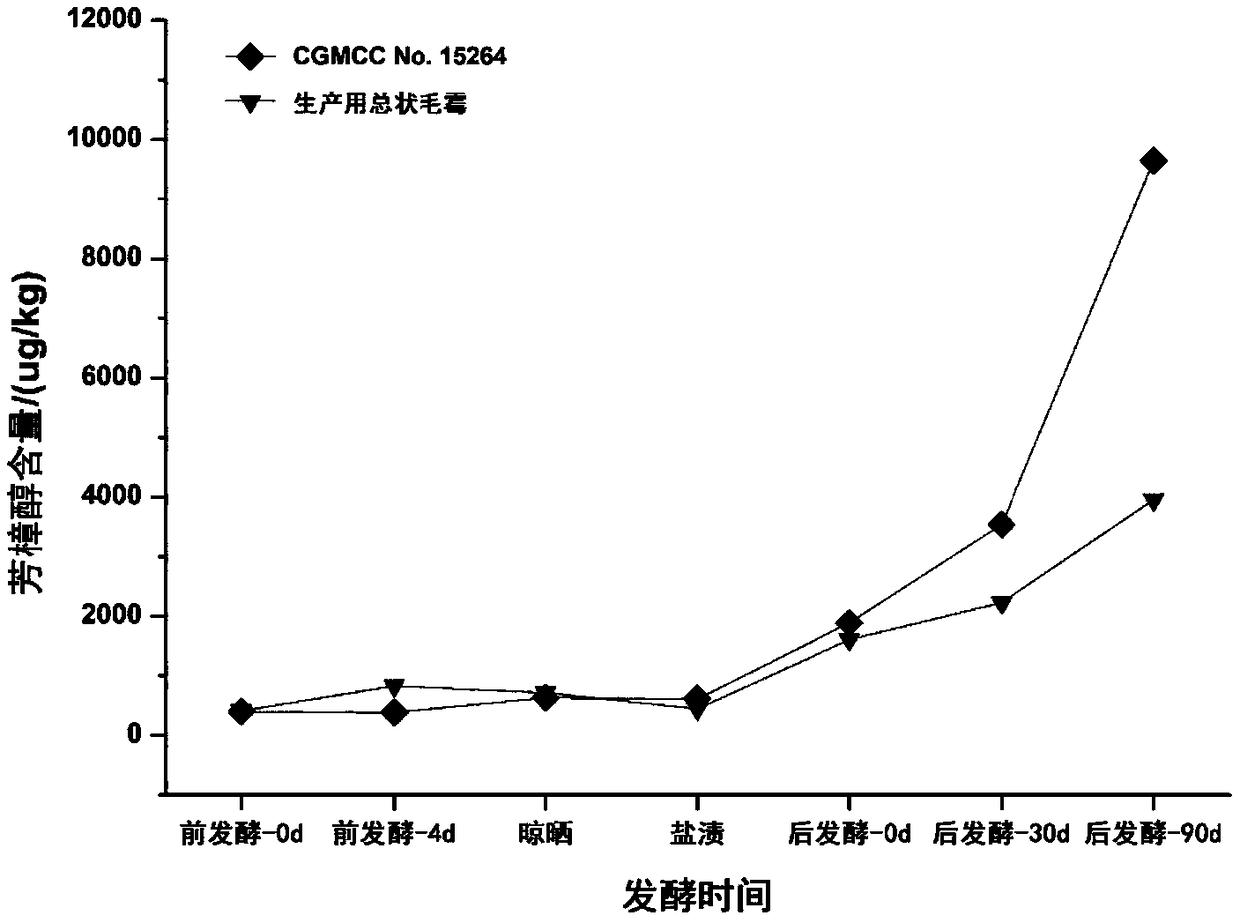

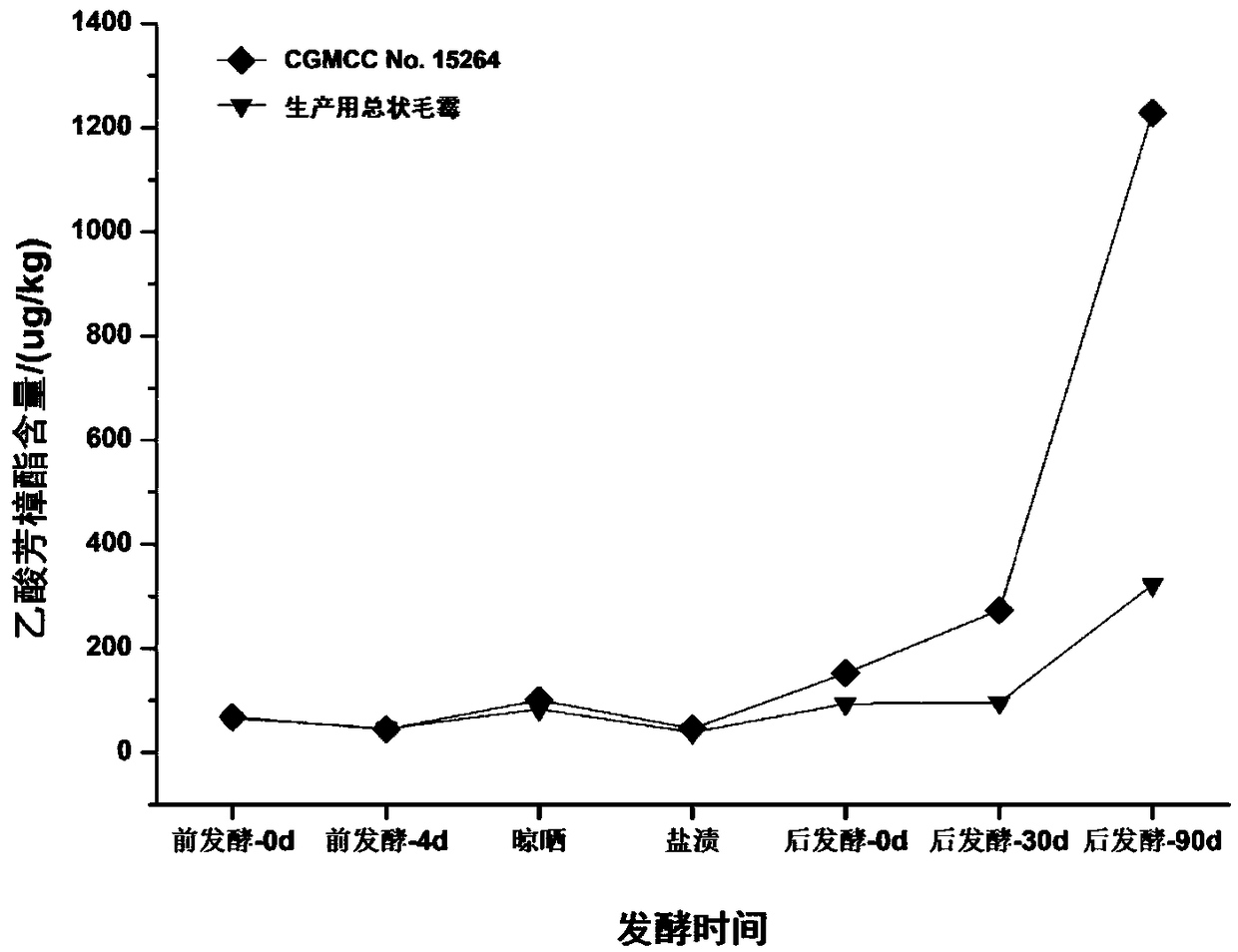

[0054] Embodiment 2: fermented bean curd with Mucor racemosa CGMCC No.15264

[0055] Mucor racemosa CGMCC No.15264 can be used in the fermentation of fermented bean curd, which can increase the content of linalool and linalyl acetate, and enhance the floral and fruity aroma of fermented bean curd.

[0056] 1. Content changes of linalool and linalyl acetate in fermented fermented bean curd by Mucor racemosus CGMCC No.15264

[0057] (1) GC-MS determination of linalool and linalyl acetate in fermented bean curd

[0058] The chromatographic conditions are: Rtx-WAX capillary column; column specification: 30m×0.25μm×0.25mm, inlet temperature is 230°C, column flow rate is 1mL / min, carrier gas is helium; temperature program: initial temperature 45°C (keep 1min ), rising to 185°C at 5°C / min (holding for 1min), rising to 240°C at 10°C / min (holding for 8min).

[0059] The mass spectrometry conditions are: ionization mode EI, electron energy 70eV, ion source temperature 230°C, interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com