Small-grain walnut-flavored peanut and preparation process thereof

A technology of small grains and walnuts, applied in the field of small grains of walnut-flavored peanuts and its production process, can solve the problems of difficulty in satisfying consumers' appetites, difficulty in ensuring consumers' health, and light walnut flavor, and achieve a fresh and unique taste. The effect of fresh and natural taste and strong walnut flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

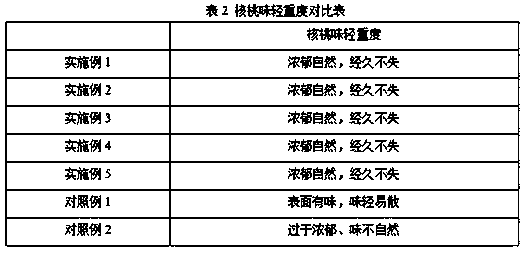

[0021] This embodiment provides a kind of small grain walnut-flavored peanut, which is boiled from peanuts and seasoning, and the seasoning includes the following raw materials in parts by weight: 30 parts of walnuts, 20 parts of edible salt, 12 parts of edible sugar, and 5 parts of flavor enhancer 5 parts, 5 parts of cooking wine, 1 part of linolenic acid, 3 parts of barley, 1 part of Chinese prickly ash, 1 part of dried longan, 0.5 part of creamer, 0.1 part of astragalus, 0.1 part of star anise; wherein, the edible salt is seaweed iodized salt, and the Edible sugar is a mixture of brown sugar, maltose and white sugar with a weight ratio of 20:5:1, and the flavor enhancer is a mixture of osmanthus fragrans, mint and leucine with a weight ratio of 3:5:1.

[0022] This embodiment also provides a method for making small grain walnut-flavored peanuts, comprising the following steps:

[0023] Step 1. Peeling: Wash the small grains of peanuts and peel them, then boil them in boilin...

Embodiment 2

[0027] This embodiment provides a kind of small-grain walnut-flavored peanut, which is boiled from peanuts and seasoning, and the seasoning includes the following raw materials in parts by weight: 31 parts of walnuts, 22 parts of edible salt, 14 parts of edible sugar, and 7 parts of flavor enhancer 6 parts of cooking wine, 1 part of linolenic acid, 3 parts of coix seed, 2 parts of Chinese prickly ash, 1 part of dried longan, 0.6 part of creamer, 0.2 part of astragalus, 0.1 part of star anise; wherein, the edible salt has a weight ratio of 1:2 The mixture of bamboo salt and seaweed iodized salt, the edible sugar is a mixture of brown sugar, maltose and white sugar with a weight ratio of 22:7:3, and the flavor enhancer is osmanthus fragrans with a weight ratio of 5:7:3, A blend of peppermint and leucine.

[0028] This embodiment also provides a method for making small grain walnut-flavored peanuts, comprising the following steps:

[0029] Step 1. Peeling: Wash the small grains ...

Embodiment 3

[0033]This embodiment provides a kind of small-grain walnut-flavored peanuts, which are boiled from peanuts and seasonings, and the seasonings include the following raw materials in parts by weight: 32 parts of walnuts, 24 parts of edible salt, 15 parts of edible sugar, and 8 flavor enhancers 7 parts of cooking wine, 2 parts of linolenic acid, 4 parts of coix seed, 2 parts of Chinese prickly ash, 2 parts of dried longan, 0.8 part of creamer, 0.2 part of astragalus, 0.2 part of star anise; wherein, the edible salt is 3:2 by weight The mixture of bamboo salt and seaweed iodized salt, the edible sugar is a mixture of brown sugar, maltose and white sugar with a weight ratio of 23:8:3, and the flavor enhancer is osmanthus fragrans with a weight ratio of 5:6:3, A blend of peppermint and leucine.

[0034] This embodiment also provides a method for making small grain walnut-flavored peanuts, comprising the following steps:

[0035] Step 1. Peeling: Wash the small grains of peanuts an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com