Aroma-strengthening system

A technology of flavoring and atomization equipment, applied in the field of flavoring system, which can solve the problems of uneven spraying, complicated cover making, and long time, so as to improve the uniformity and fineness of powder coating, improve the uniformity and fullness of flavoring Sex, the effect of increasing the time of staying in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

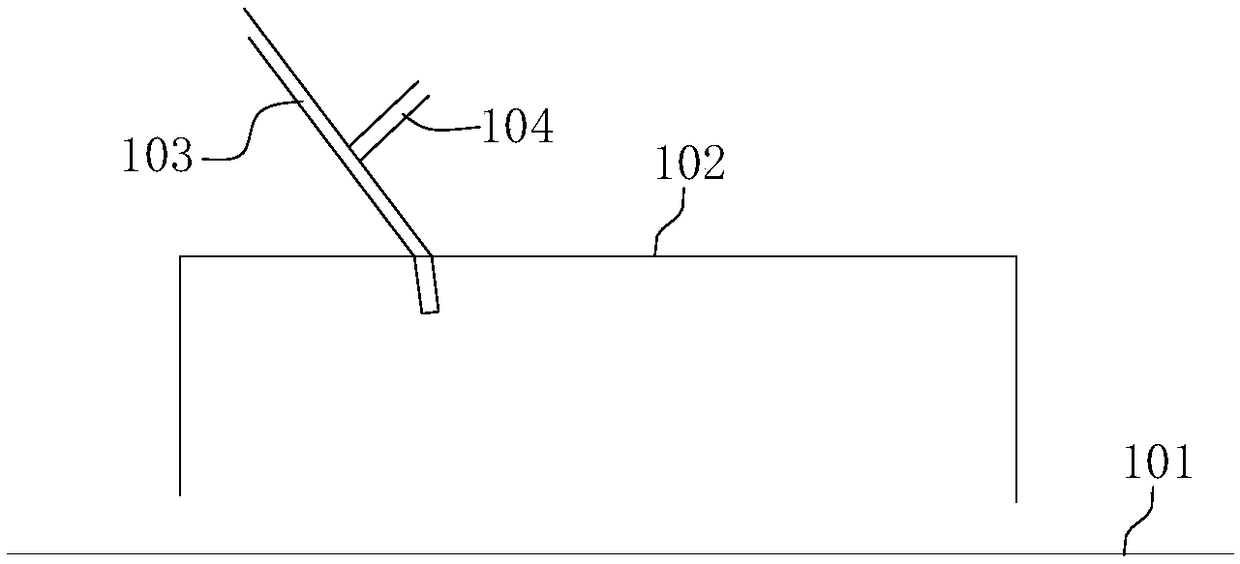

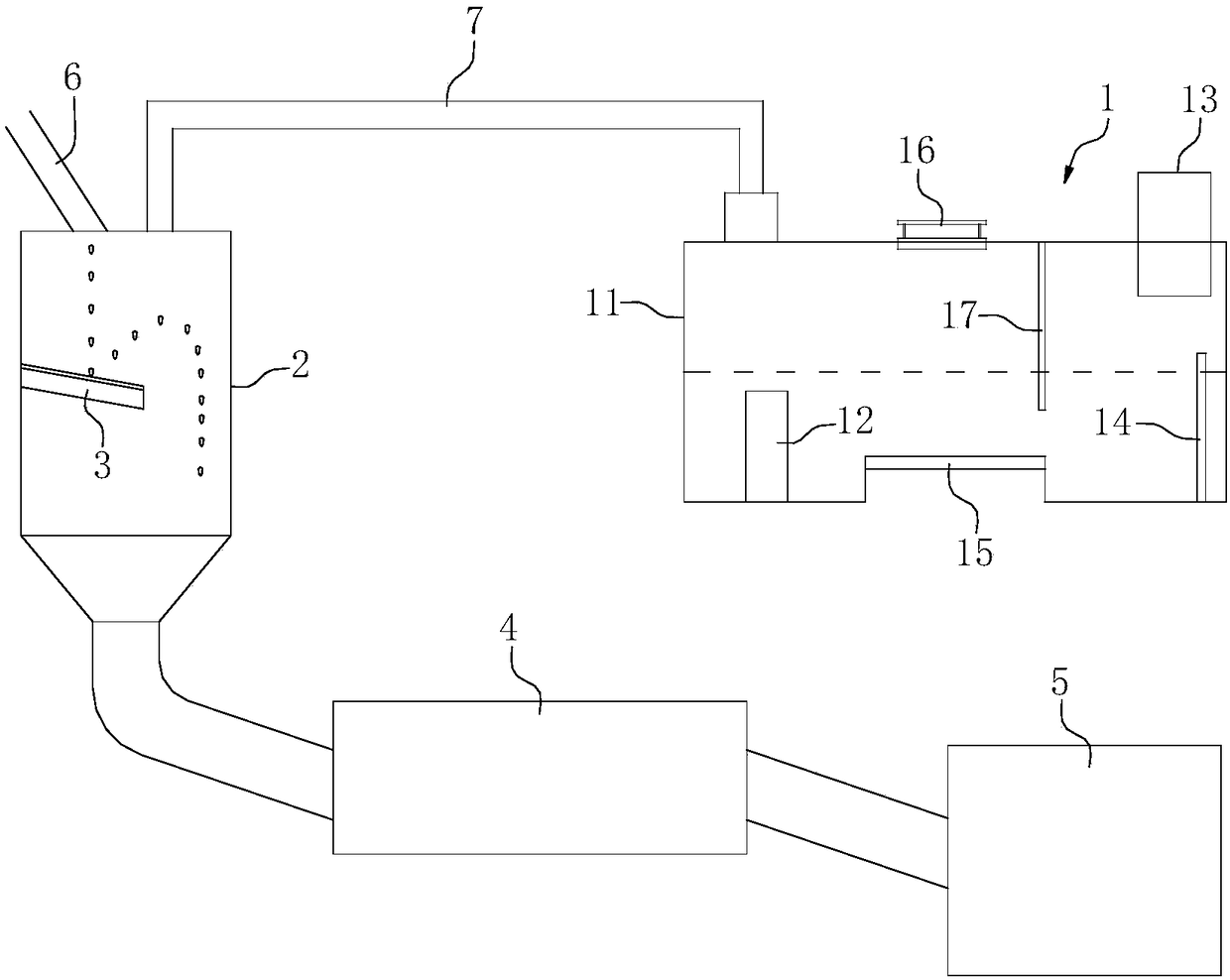

[0036] See attached figure 2 .

[0037] Perfuming system of the present invention comprises:

[0038] Atomization device 1, used to atomize the essence liquid;

[0039] The mixing tank 2 communicates with the mist outlet of the atomization device 1 and is used to provide a place where the atomized essence liquid contacts with the material;

[0040] The bulk material plate 3 is arranged in the mixing tank 2 , and is used for bouncing and splashing the incoming materials, scattering them in multiple directions, and then falling to the bottom of the mixing tank 2 .

[0041] The invention uses atomization equipment to atomize the essence liquid. Compared with the prior art, the mist droplets formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com