Injected face filler compound gel for cosmetic plastic surgery and preparation method thereof

A filler and injection-type technology, which is applied in the field of injection-type facial filler composition gel for cosmetic plastic surgery and its preparation, can solve problems such as inability to fill, increased extrusion force, and short residence time of hyaluronic acid. Achieve the effect of easy clinical injection and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

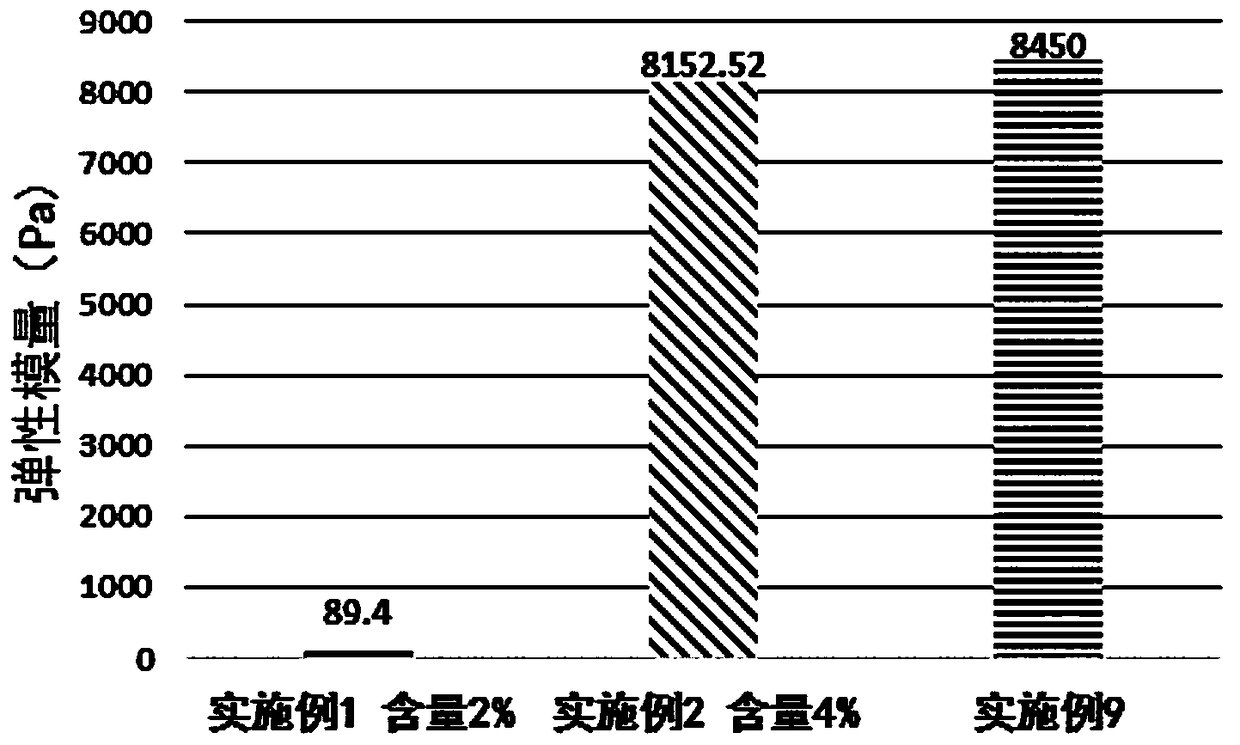

[0053] Example 1 Preparation of a single gel composition (HP) with 1%, 2%, 4% hyaluronic acid and with 30% hydroxyapatite microparticles (comparative gels).

[0054] An HP gel composition with a sodium hyaluronate concentration of 1% was prepared.

[0055] Add 1 g of HA to 100.9 g of solution A under slow stirring, fully wet and swell, and let it stand for 6 hours to obtain a clear and transparent solution or gel. Then add 43.67g of hydroxyapatite and grind or stir for 10min to make it mix into a homogeneous phase.

[0056] According to the formula in Example 1 in Table 1, the formulation amounts of HA, hydroxyapatite and solution A were weighed, and the preparation method was the same as that of the HP gel composition with 1% sodium hyaluronate.

[0057] Table 1: The formula composition of embodiment 1,2,3

[0058]

Embodiment 2

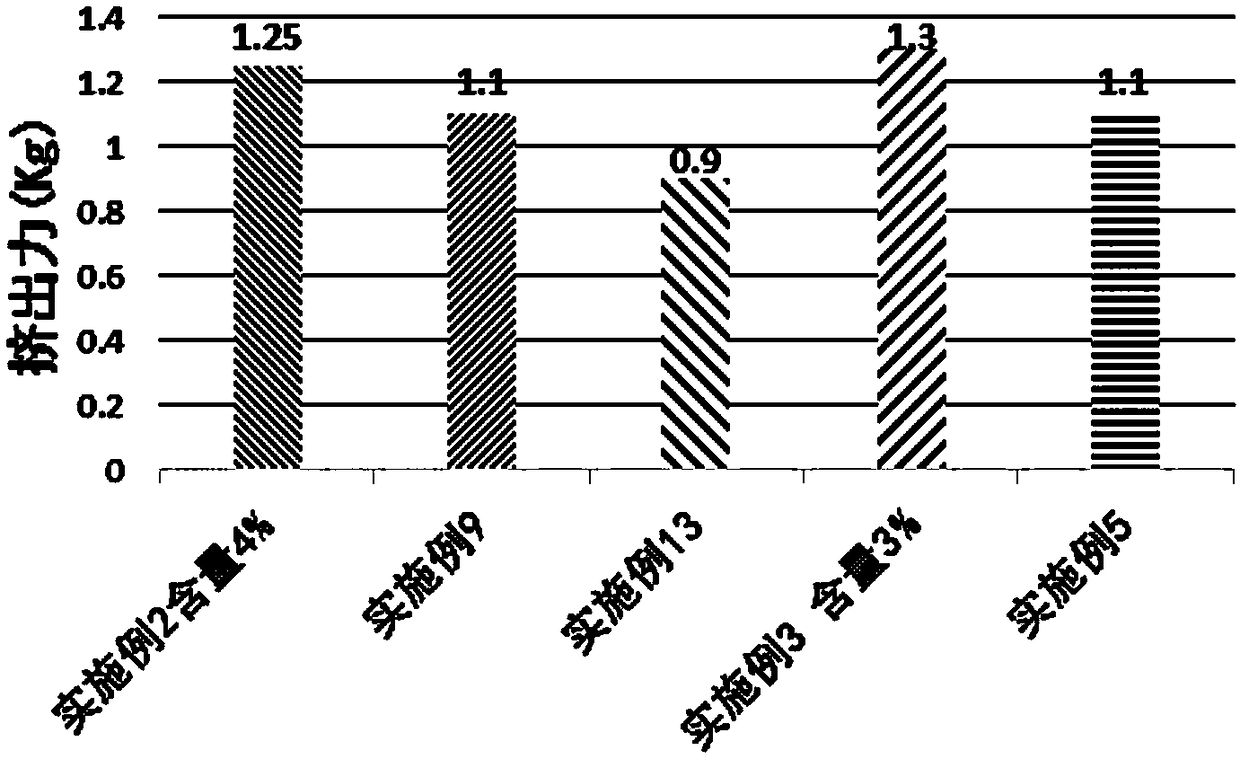

[0059] Example 2 Preparation of a single gel composition (MP) with 1%, 3%, 5% methylcellulose (MC) and with 30% hydroxyapatite (CaHAP) microparticles (comparative gels).

[0060] The specific formula is shown in Table 1, Example 2, the preparation method is the same as that of the HP gel composition of 1% sodium hyaluronate in Example 1, and sodium hyaluronate is replaced by sodium methylcellulose in this example. Can.

Embodiment 3

[0061] Example 3 Preparation of a single gel composition (CP) with 2%, 4%, 6% carboxymethylcellulose sodium (CMC-Na) and with hydroxyapatite (CaHAP) microparticles (comparative gels)

[0062] The specific formula is shown in Table 1, Example 3, the preparation method is the same as that of the HP gel composition of 1% sodium hyaluronate in Example 1, and the sodium hyaluronate is replaced by the methyl cellulose in this example. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com