Postoperative auxiliary rehabilitation device for vascular surgery

A post-surgery, rehabilitation device technology, applied in the field of medical devices, can solve the problems of boring exercise process, prolong the patient's recovery time, easy to sweat, etc., and achieve the effect of promoting the patient's recovery, shortening the recovery time, and maintaining physical and mental health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

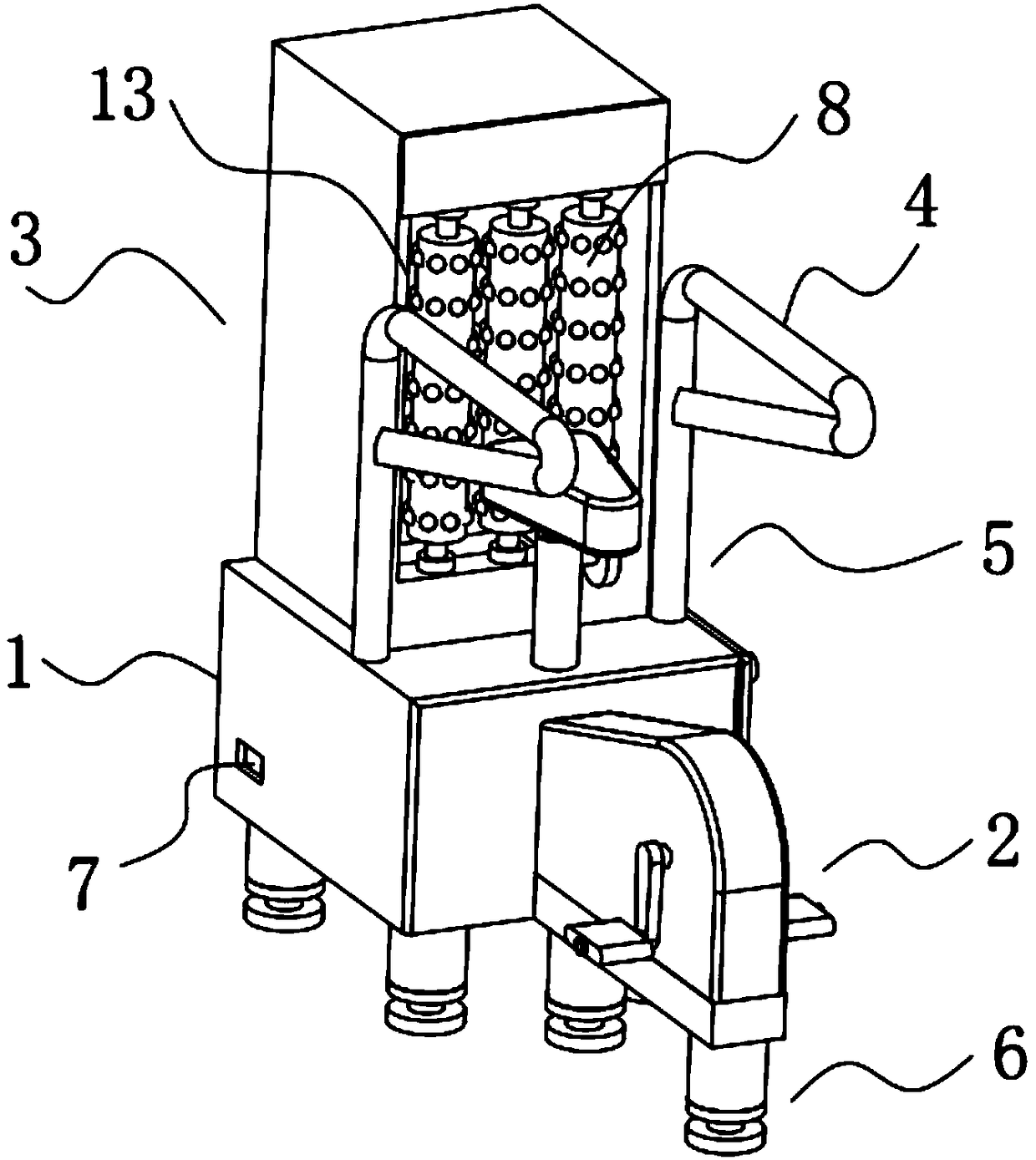

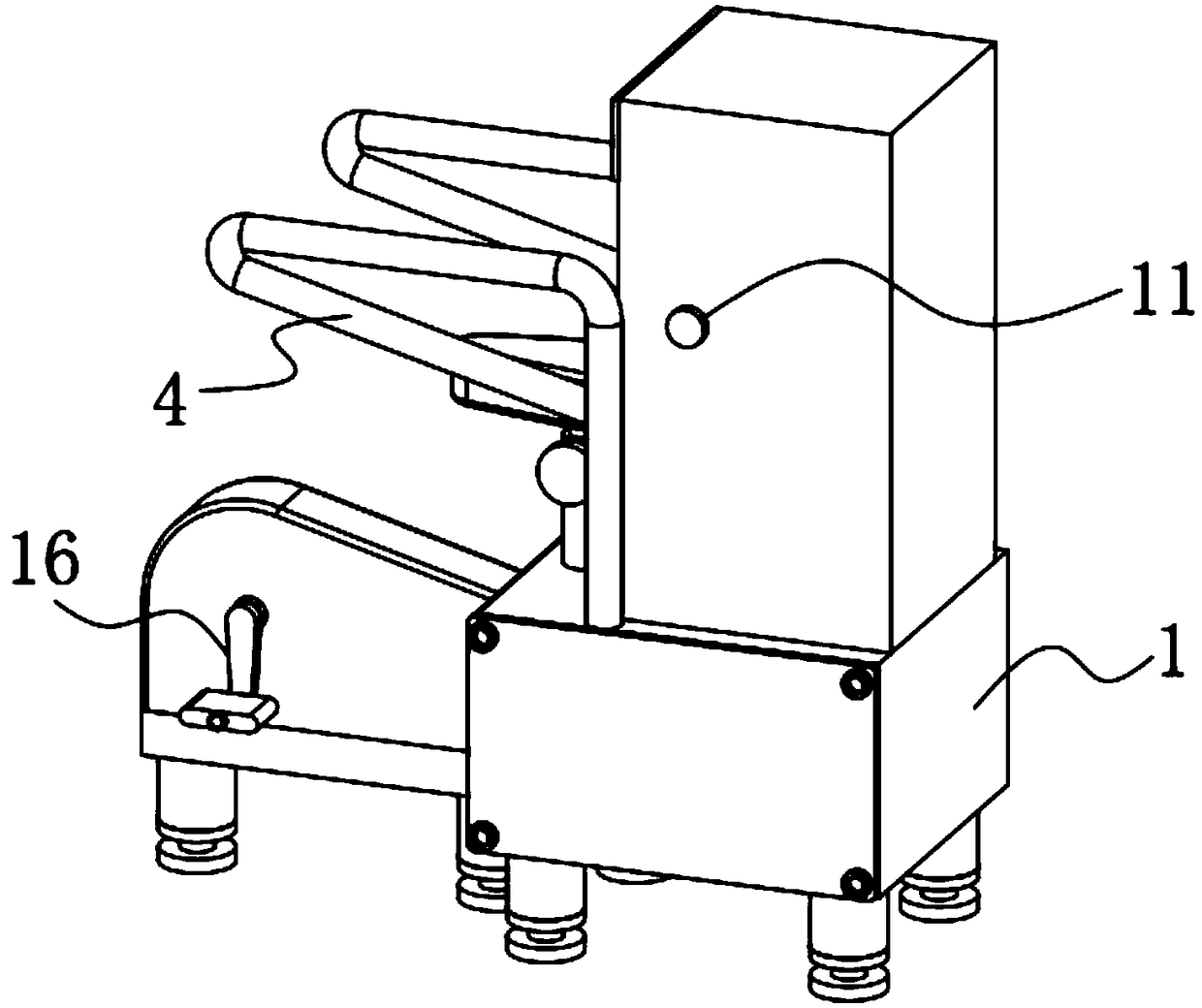

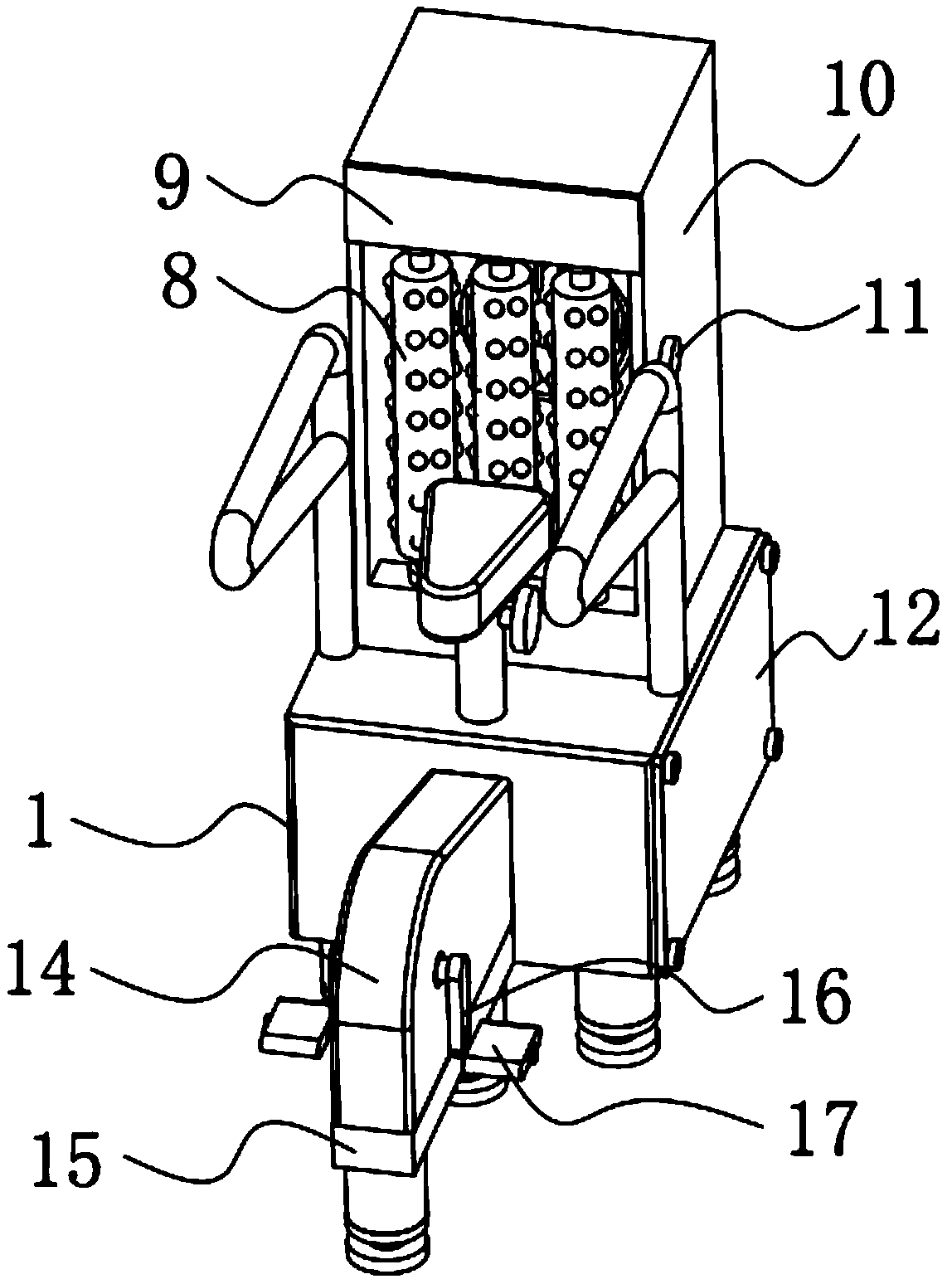

[0058] The following is attached Figure 1-13 The present invention is described in further detail.

[0059] An auxiliary rehabilitation device after vascular surgery, such as Figure 1-13 As shown, it includes a hollow base 1, one side of the hollow base 1 is provided with a lower limb exercise device 2, and the upper part of the hollow base 1 is provided with a back exercise device 3, and the upper part of the hollow base 1 is located on the lower limb exercise device. A hip support device 5 is provided between the device 2 and the back exercise device 3;

[0060] The lower limb exercise device 2 includes a support beam 15 welded on one side of the hollow base 1, the upper part of the support beam 15 is fixedly installed with an arc-shaped housing 14 communicating with the hollow base 1, the arc The inside of the shaped housing 14 is equipped with a connecting shaft 28 through two first rolling bearings 29, the middle part of the connecting shaft 28 is fixedly fitted with ...

Embodiment 2

[0073] The difference from Example 1 is that the surface of the hollow base 1 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0074] Take the following raw materials and weigh them by weight: 30 parts of porcelain powder, 12 parts of zinc oxide powder, 15 parts of p-toluenesulfonic acid powder, 6 parts of alumina powder, 18 parts of epoxy resin, 3 parts of paraffin wax, 8 parts of cobalt naphthenate , 1 part of silane coupling agent and 40 parts of ethanol;

[0075] S1, add the weighed paraffin, silane coupling agent and ethanol into the mixer and stir for 20min, the stirring speed is 600r / min, to prepare a mixed solution;

[0076] S2, adding porcelain powder, zinc oxide powder, p-toluenesulfonic acid powder, aluminum oxide powder, epoxy resin and cobalt naphthenate into a ball mill for fine grinding until the particle diameter is 20um to obtain a mixed powder material;

[0077] S3. Add the mixed solution prepared in s...

Embodiment 3

[0082] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0083] Take the following raw materials and weigh them by weight: 35 parts of porcelain powder, 15 parts of zinc oxide powder, 18 parts of p-toluenesulfonic acid powder, 8 parts of alumina powder, 22 parts of epoxy resin, 4 parts of paraffin wax, 10 parts of cobalt naphthenate , 2 parts of silane coupling agent and 50 parts of ethanol;

[0084] S1. Add the weighed paraffin, silane coupling agent and ethanol into the mixer and stir for 25min at a stirring speed of 700r / min to prepare a mixed solution;

[0085] S2, adding porcelain powder, zinc oxide powder, p-toluenesulfonic acid powder, aluminum oxide powder, epoxy resin and cobalt naphthenate into a ball mill for fine grinding until the particle diameter is 30um to obtain a mixed powder material;

[0086] S3. Add the mixed solution prepared in step S1 and the mixed powder material prepared in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com