A vocs waste gas treatment method combining absorption and adsorption

A waste gas treatment and adsorption phase technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of absorbent selectivity, water content interference, high regeneration energy consumption, etc., to reduce energy consumption and improve recovery rate , Improve desorption efficiency and recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

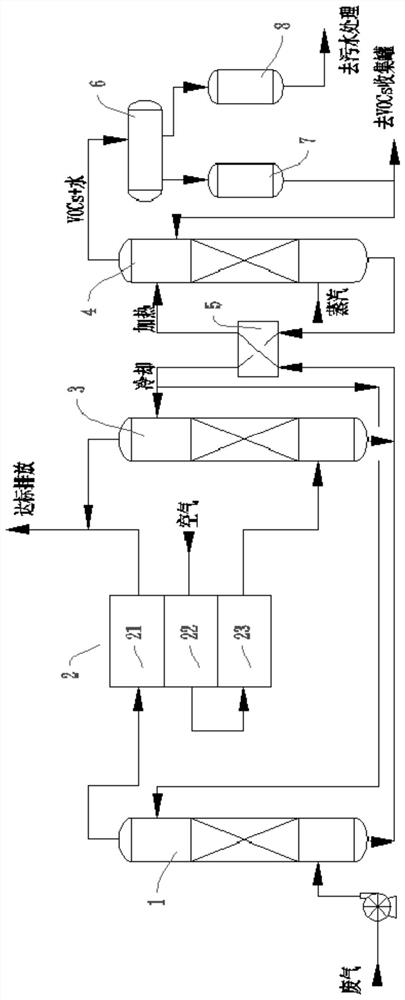

[0021] In order to better understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Take the exhaust gas discharged by a pharmaceutical company as an example, the gas volume is 16000m 3 / h, the exhaust emissions mainly contain VOCs such as styrene, toluene, methanol, ethanol, etc., with a total content of 4000mg / m 3 , each component needs to be reduced to 40mg / m 3 The following emission standards are met.

[0023] The VOCs exhaust gas collected in the workshop is transported to the bottom of the first absorption tower 1, and the absorbent enters from the top of the tower. The first absorption tower 1 is under normal temperature and pressure conditions, and the absorbent and the exhaust gas are in countercurrent contact, and the VOCs are dissolved in the absorbent. The first absorbent-rich liquid of VOCs such as styrene, toluene, methanol, ethanol, etc. is extracted from the tower kettle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com