Production method of cylindrical and tubular mechanical part

A technology of mechanical parts and production methods, which is applied in the field of mechanical processing, can solve problems such as high pollution and high energy consumption, and achieve the effects of low equipment investment, short production process and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

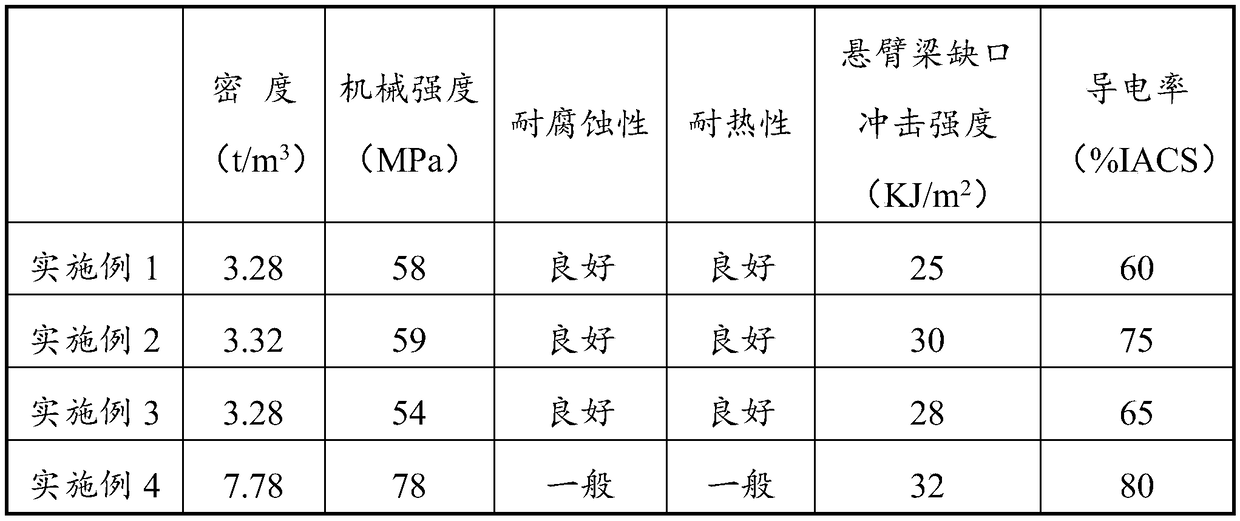

Examples

Embodiment 1

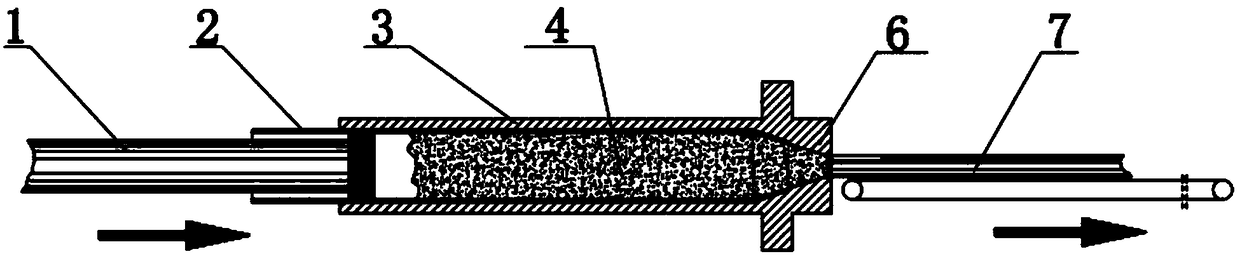

[0030] A method for producing an extruded wafer butterfly valve body, comprising the steps of:

[0031] 1) Raw material preparation: using reduced iron powder mixed evenly with TFe 98.28%, ηFe 98.5%, C0.48%, fineness 5-74μm as raw material A, to "Fangxin brand" FX-199 m-phthalic unsaturated poly Add liquid curing agent methyl ethyl ketone peroxide I to the ester resin, and mix the two evenly as raw material B, wherein the amount of unsaturated polyester resin is 10% of the weight of reduced iron powder, and the amount of liquid curing agent is liquid unsaturated polyester resin 2% by weight;

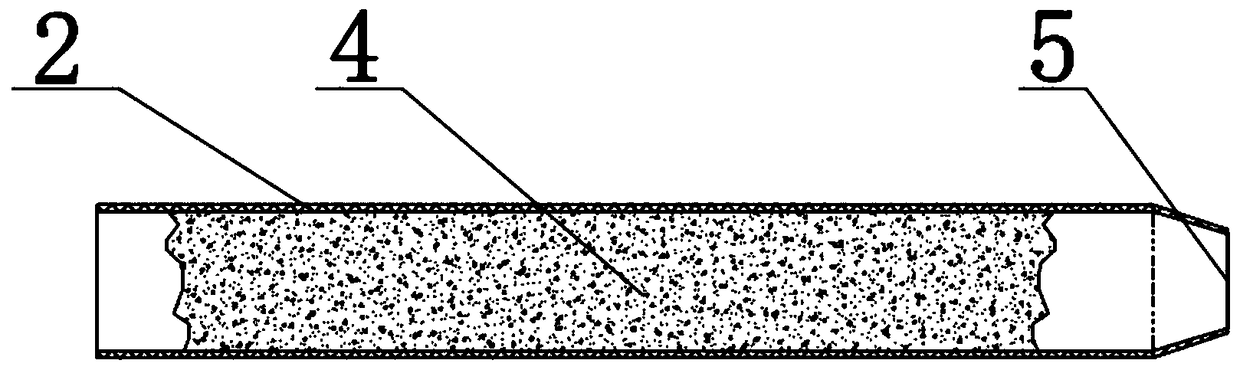

[0032] 2) Mixing and grinding, putting into a ladle: Pour raw material B into raw material A, stir and mix evenly, and then mix and grind for 15 minutes to obtain "dough"-like mixture 4, and put the obtained mixture into the inner and outer walls of which are coated with a layer of Vaseline. Ladle cover 2;

[0033] 3) Vacuum treatment: place the ladle containing the "dough" mixture at ...

Embodiment 2

[0038] A production method of an extruded shaft coupling, comprising the steps of:

[0039] 1) Raw material preparation: using reduced iron powder mixed evenly with TFe 98.28%, ηFe 98.5%, C0.48%, fineness 5-74μm as raw material A, to Nantong Fangxin Chemical Company to produce "Fangxin Brand" FX- Add "Fangxin brand" liquid curing agent methyl ethyl ketone peroxide into the 3502 type liquid resin, and mix the two evenly as raw material B. The amount of resin is 10% of the weight of reduced iron powder, and the amount of liquid curing agent is resin 2% by weight;

[0040] 2) Mixing and grinding, putting into a ladle: Pour raw material B into raw material A, stir and mix evenly, and then mix and grind for 20 minutes to obtain "dough"-like mixture 4, and put the obtained mixture into the inner and outer walls of which are coated with a layer of Vaseline Ladle cover 2;

[0041] 3) Vacuum treatment: place the ladle containing the "dough" mixture at -0.012MPa to vacuumize for 6 min...

Embodiment 3

[0046] A method for producing an extruded motor casing, comprising the steps of:

[0047] 1) Raw material preparation: using reduced iron powder mixed evenly with TFe 98.28%, ηFe 98.5%, C0.48%, fineness 5-74μm as raw material A, to Nantong Fangxin Chemical Company to produce "Fangxin Brand" FX- Add "Fangxin brand" liquid curing agent methyl ethyl ketone peroxide to the 7102 type resin, and mix the two evenly as raw material B. The amount of resin is 20% of the weight of the reduced iron powder, and the amount of liquid curing agent is the weight of the resin 0.5% of;

[0048] 2) Mixing and milling, putting into a ladle: Pour raw material B into raw material A, stir and mix evenly, and then mix and mill for 18 minutes to obtain "dough"-like mixture 4, put the obtained mixture into the inner and outer walls and apply a layer of detergent Refined ladle set 2;

[0049] 3) Vacuum treatment: place the ladle containing the "dough" mixture at -0.015MPa and vacuumize for 10 minutes;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com