Production device of pipe body, and production method of strengthening pipe body based on device

A technology for producing a device and a pipe body, applied in the field of pipe body, can solve the problems of paint peeling, poor filling uniformity, inapplicability, etc., and achieve the effect of reducing the frequency of secondary processing, avoiding large inclination, and avoiding stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

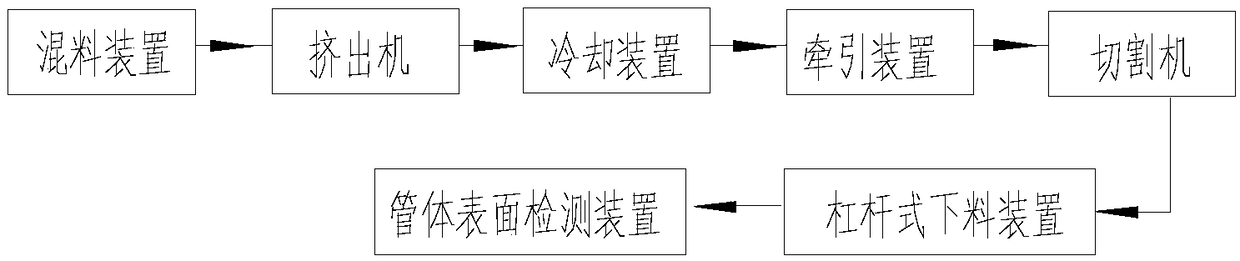

[0047] like figure 1 As shown, this embodiment discloses a pipe body production device, which includes a mixing device, an extruder, a cooling device, a cutting machine, a lever type feeding device, and a pipe body surface detection device from front to back according to the technological process.

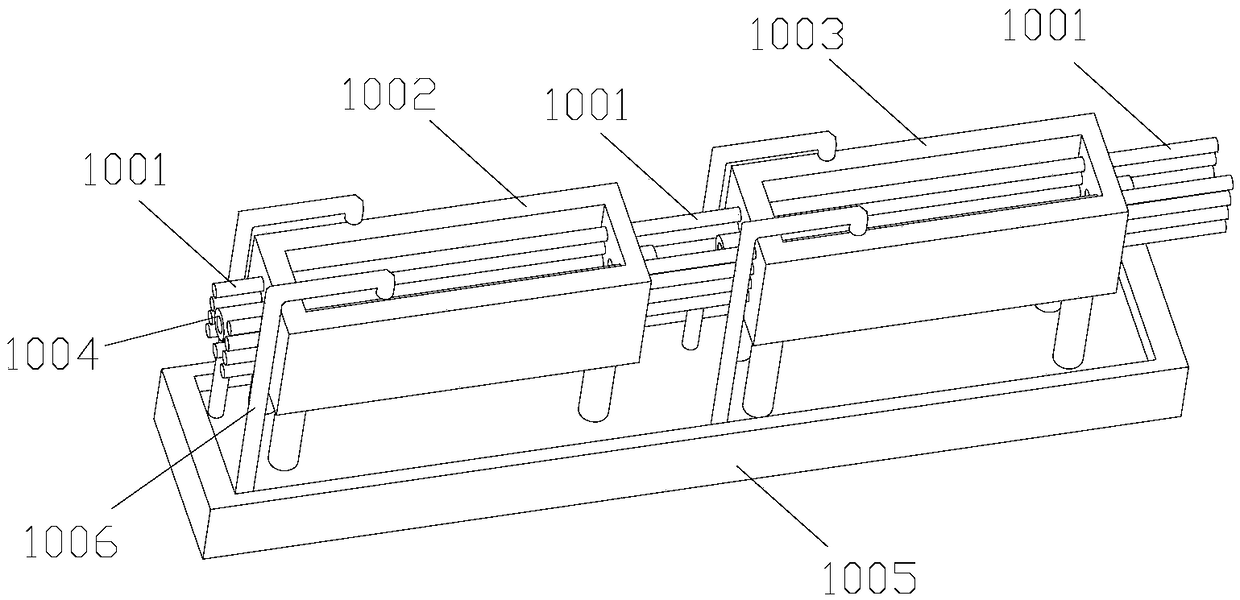

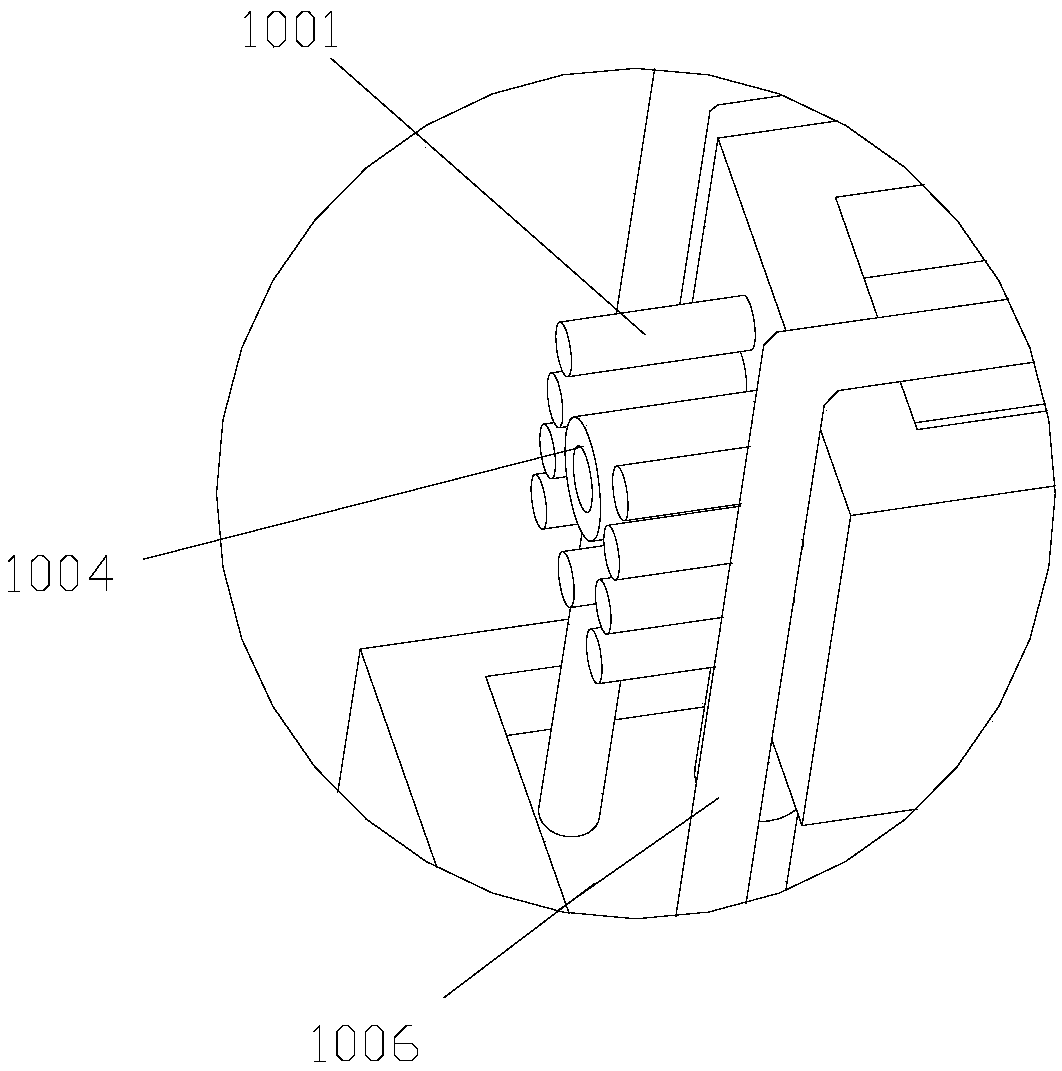

[0048] like Figure 2-3 As mentioned above, the cooling device includes a cooling heat exchange pipe 1001 and a water-cooled tank assembly; the cooling heat exchange pipe 1001 is arranged in the water-cooled tank assembly, and the water-cooled tank assembly includes a plurality of water-cooled tanks, and the cooling sequence is from front to back Arranged sequentially; the number of cooling heat exchange pipes 1001 is multiple and connected in parallel with each other, and each cooling heat exchange pipe 1001 extends from the beginning of the water-cooling tank at the starting position to the end of the water-cooling tank at the end position.

[0049] like Figure 4-6 As shown, t...

Embodiment 2

[0065] This embodiment discloses a method for producing a reinforced pipe body 11 using the production device of the pipe body in Embodiment 1. Step 1: After mixing polyvinyl chloride resin and glass fiber modified polypropylene in a mixing device, add titanate Coupling agent, vinyltrimethoxysilane, calcium carbonate, n-octadecyl propionate, titanium dioxide, and benzophenone-type ultraviolet absorbers are mixed;

[0066] Step 2: After being extruded by an extruder, the product is obtained after successively sizing, cooling, pulling, cutting, and testing.

[0067] Preferably, 70~90 parts of polyvinyl chloride resin, 1~3 parts of titanate coupling agent, 1~2 parts of vinyltrimethoxysilane, 10~20 parts of glass fiber modified polypropylene, 20~20 parts of calcium carbonate 35 parts, 0.1 to 0.5 parts of n-octadecanyl propionate, 1 to 2 parts of titanium dioxide, 2 to 5 parts of benzophenone ultraviolet absorbers; the temperatures of the extruder from the hopper to the die are res...

Embodiment 3

[0069] Such as Figure 10-12 As shown, this embodiment discloses a composite pipe body 11, which sequentially includes raw material mixing, extrusion, cooling, pulling, and cutting. The tube body 11 includes an inner layer tube body 111 and an outer layer tube body 112, and a gap layer is formed between the inner layer tube body 111 and the outer layer tube body 112;

[0070] A skeleton 13 is arranged in the gap layer, and the two ends of the skeleton 13 are respectively connected with the inner layer pipe body 111 and the outer layer pipe body 112; Surrounding the center at intervals, an accommodating cavity 14 is formed between the adjacent skeleton 13 and the inner tube body 111 and the outer tube body 112 .

[0071] The pipe body 11 is prepared from the following raw materials in parts by mass: 70-90 parts of polyvinyl chloride resin, 1-3 parts of titanate coupling agent, 1-2 parts of vinyltrimethoxysilane, glass fiber modified 10-20 parts of polypropylene, 20-35 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com