Disilane preparation device

A preparation device and disilane technology, applied in the direction of silicon hydride, etc., can solve the problems of limitations, difficult synthesis, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

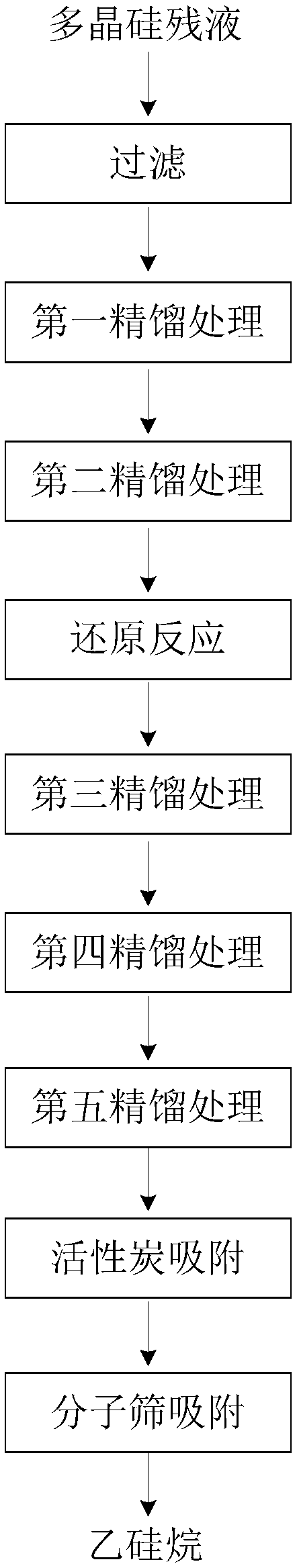

[0020] In the production process of modified Siemens polysilicon, a small amount of chlorodisilane will be produced in the reduction process and hydrogenation process. Chlorodisilane is monochlorodisilane, dichlorodisilane, trichlorodisilane, tetrachlorodisilane, pentachlorodisilane A mixture of disilane and hexachlorodisilane, after concentration, the above-mentioned chlorodisilane is enriched in the polysilicon raffinate.

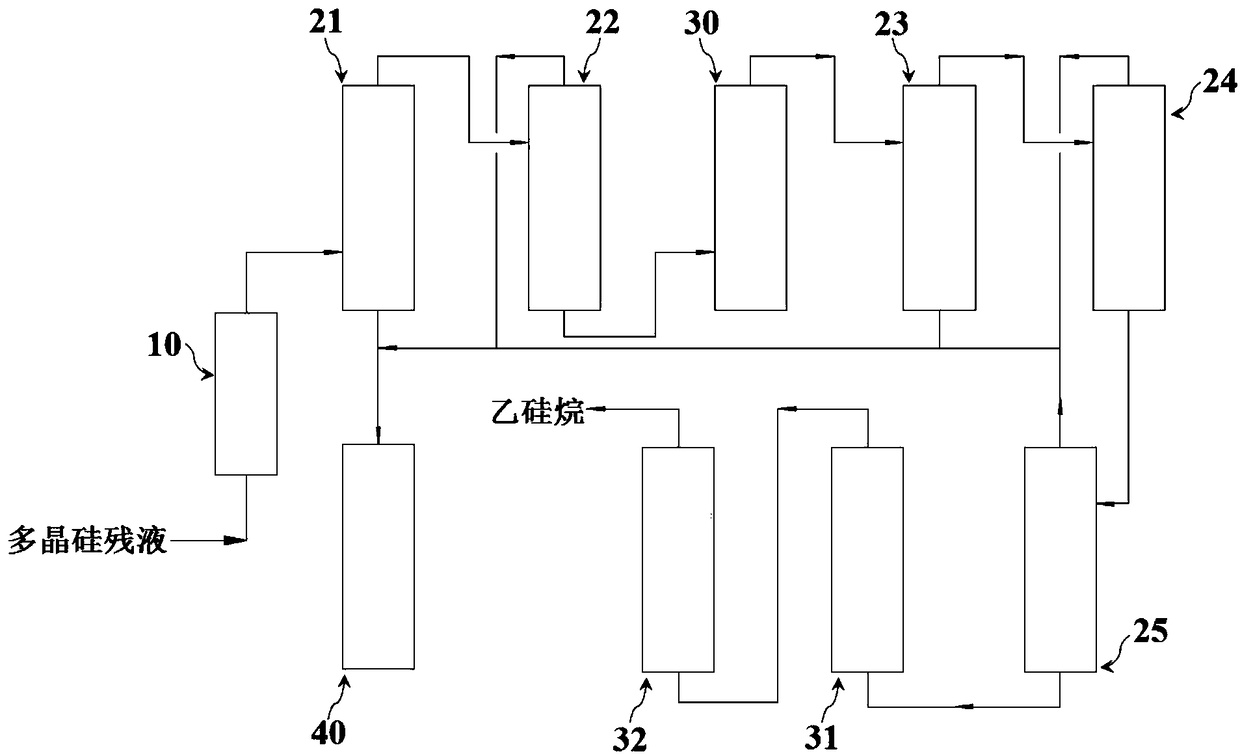

[0021] One embodiment of the present invention provides a disilane preparation device, which can be used to recover and refine chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com