Anaerobic microbial filler

An anaerobic microorganism and filler block technology, which is applied in anaerobic digestion treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as environmental accidents, microbial diseases, and substandard effluent quality, and achieve The effect of effluent water quality up to standard, disease prevention and environmental protection accident prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

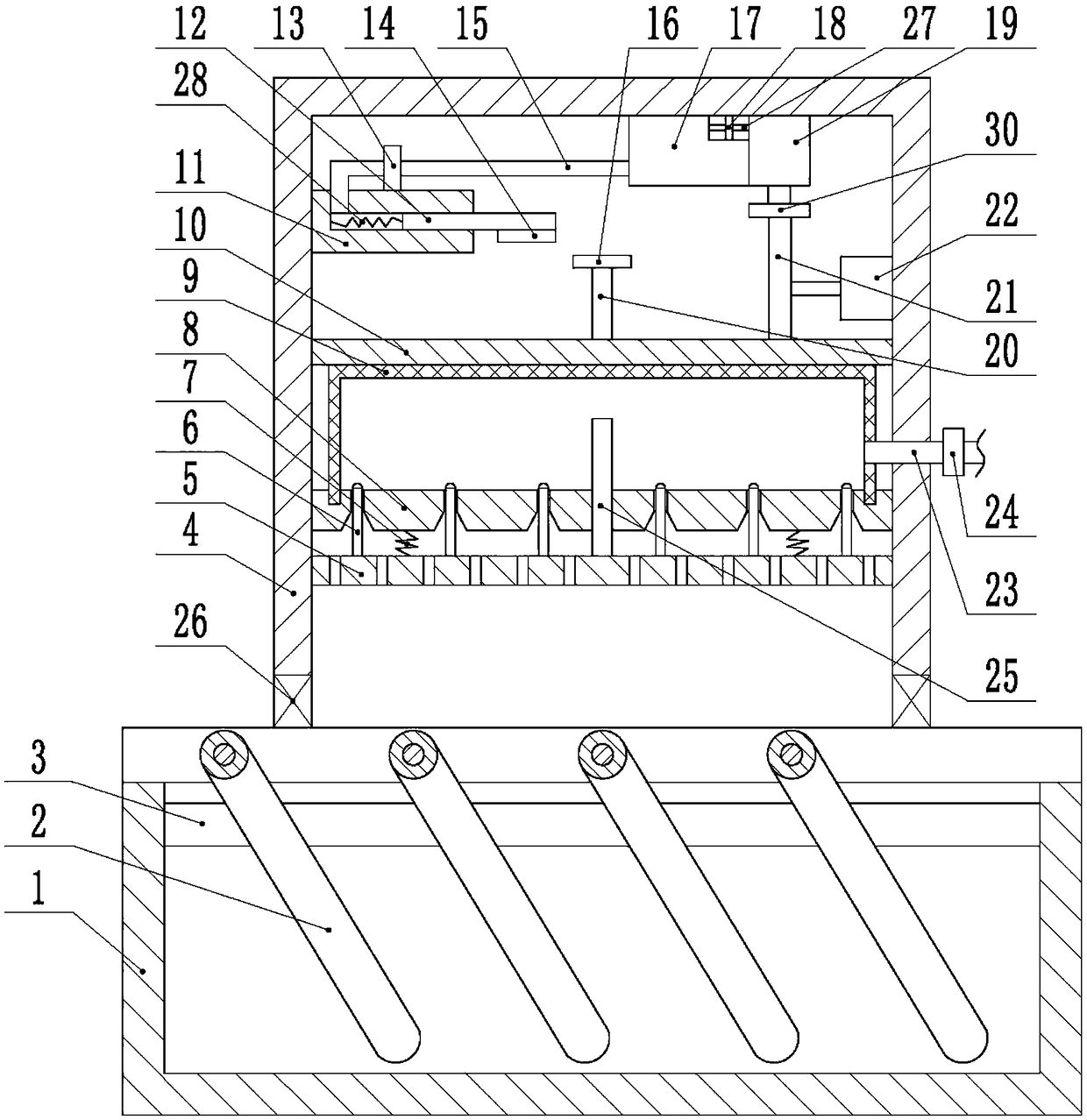

[0016] Embodiment one is basically as attached figure 1 Shown: anaerobic microbial packing, including support frame 1, second packing block 3 and four first packing blocks 2, each first packing block 2 is hinged on the supporting frame 1, and each first packing block 2 is Obliquely fixed on the second filler block 3, the second filler block 3 and the four first filler blocks 2 are made of polyethylene or vinylon by injection molding, the second filler block 3 and the four first filler blocks Each filler block 2 needs to be soaked in a potion for 2 months. The potion includes the following components: 8kg of nitric acid, 0.5kg of phosphoric acid, 0.8kg of iron oxide, 0.8kg of calcium sulfate, 0.8kg of magnesium oxide, 0.8kg of potassium oxide, water 135kg.

[0017] Initially, soak the four first packing blocks 2 and the second packing block 3 in the nutrient solution for 2 months, this method can provide enough microelements for the microorganisms and can last for a period of ...

Embodiment 2

[0018] Embodiment 2, on the basis of Embodiment 1, differs from Embodiment 1 in that the potion includes the following components: 10 kg of nitric acid, 1 kg of phosphoric acid, 1 kg of iron oxide, 1 kg of calcium sulfate, 1 kg of magnesium oxide, 1 kg of potassium oxide, and 140 kg of water . According to practice, the average service life of the anaerobic microbial filler in this example is 6.8 years.

Embodiment 3

[0019] Embodiment three, on the basis of embodiment one, differs from embodiment one in that the potion includes the following components: 12kg of nitric acid, 1.5kg of phosphoric acid, 1.2kg of iron oxide, 1.2kg of calcium sulfate, 1.2kg of magnesium oxide, potassium oxide 1.2kg, water 145kg. According to practice, the average service life of the anaerobic microbial filler in this example is 6.1 years.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com