Well cementing cement material with high thermal conductivity for geothermal exploitation

A technology of cementing and high thermal conductivity, which is applied in the field of cementing slurry, can solve the problems of little research on thermal conductivity, and achieve the effects of shortening the setting time, matching the compressive strength and reducing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

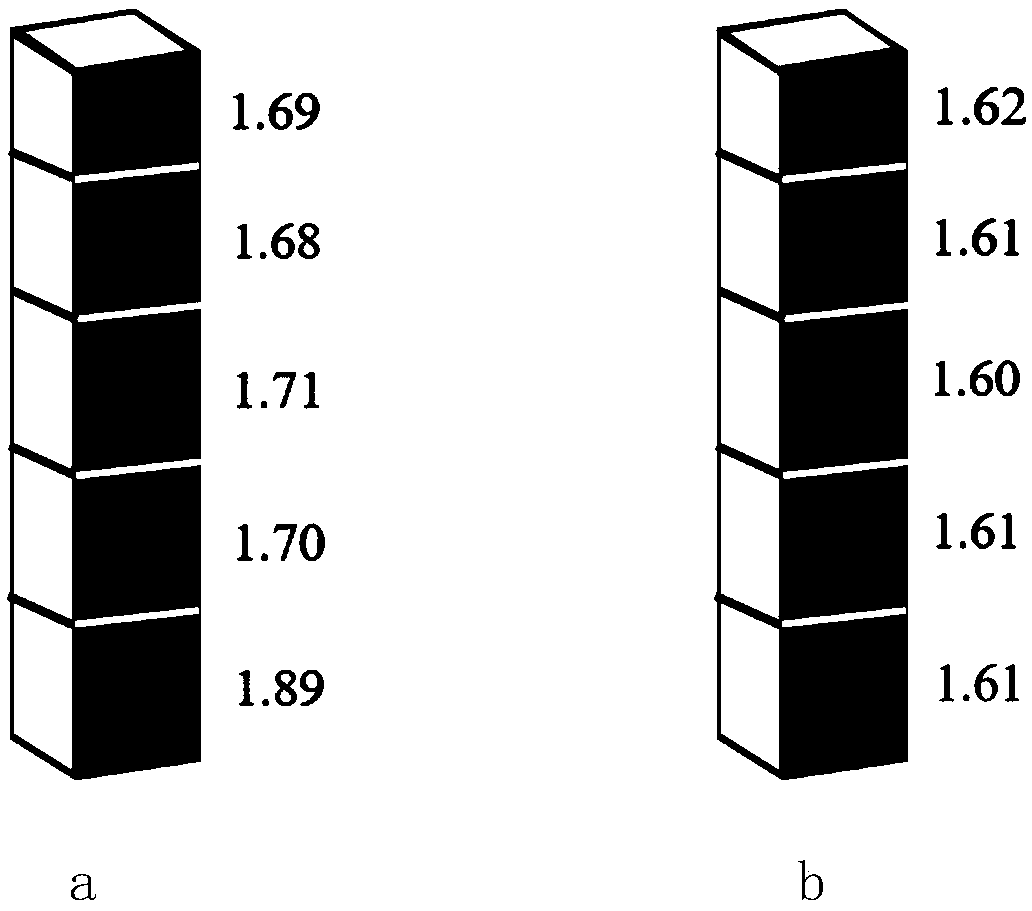

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and examples.

[0025] A cement material with high thermal conductivity for geothermal exploitation, the cement material for well cementing includes:

[0026] Water, ordinary Portland cement (P.O42.5), thermal conductivity enhancing material, JSS water reducer, sodium chloride (NaCl) and triethanolamine (TEA);

[0027] Water-cement ratio: the weight ratio of water to ordinary Portland cement: 0.6;

[0028] The following is calculated according to the mass ratio of ordinary Portland cement;

[0029] Thermal conductivity enhancement material 600 mesh graphite, the mass ratio is 10%;

[0030] The mass ratio of JSS water reducer is: 0.3%;

[0031] Sodium chloride (NaCl) mass ratio is: 0.3%;

[0032] The mass ratio of triethanolamine (TEA) is: 0.02%.

[0033] The actua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com