High performance reflective insulating gypsum-based composite insulation material and preparation method thereof

A composite thermal insulation material and gypsum-based technology, which is applied in the field of high-performance reflective thermal insulation gypsum-based composite thermal insulation materials and their preparation, can solve the problem of poor durability and climate tolerance, affecting the use energy of thermal insulation materials, and expanding perlite aggregates. Broken and other problems to achieve the effect of reducing shrinkage, improving construction performance, adjusting consistency and water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

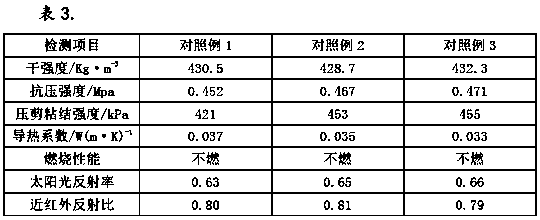

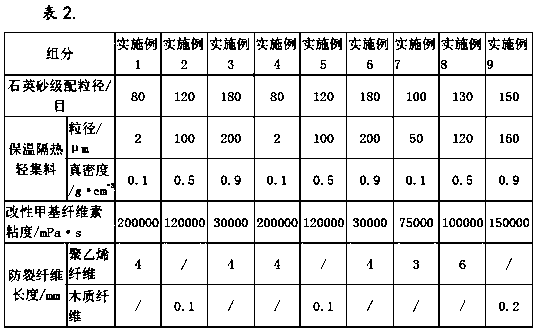

[0059] Examples 1-9 all relate to a high-performance reflective heat-insulating gypsum-based composite thermal insulation material, and the contents of each component by weight are shown in the following table:

[0060]

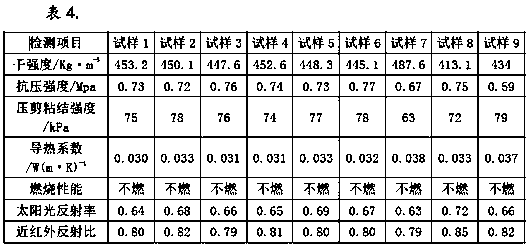

[0061] The gradation particle size of the quartz sand used in each embodiment, the particle size of the thermal insulation light aggregate, the true density of the thermal insulation light aggregate, the viscosity of the modified methyl cellulose used and the length parameter of the anti-crack fiber As shown in the table below:

[0062]

Embodiment 10

[0064] A high-performance reflective heat-insulating gypsum-based composite thermal insulation material, which is based on Example 1, the difference is that the quartz sand used has been treated with hydrophobic treatment, and the specific treatment process is as follows,

[0065] P1. Evenly spray the silicone emulsion with a mass percentage concentration of 3% on the surface of the quartz sand, and the mass ratio of the spray amount of the silicone emulsion to the quartz sand is 1:1;

[0066] P2. Bake the quartz sand treated in step P1 at 85°C until the sprayed silicone emulsion is completely dry;

[0067] P3. After the quartz sand treated in step P2 is naturally cooled to room temperature, it is sieved to obtain quartz sand with a gradation particle size of 80 meshes for use.

Embodiment 11

[0069] A high-performance reflective heat-insulating gypsum-based composite thermal insulation material, which is based on Example 2, the difference is that the quartz sand used has been treated with hydrophobic treatment, and the specific treatment process is as follows,

[0070] P1. Evenly spray the silicone emulsion with a mass percentage concentration of 3% on the surface of the quartz sand, and the mass ratio of the spray amount of the silicone emulsion to the quartz sand is 1:1;

[0071] P2. Bake the quartz sand treated in step P1 at 95°C until the sprayed silicone emulsion is completely dry;

[0072] P3. After the quartz sand treated in step P2 is naturally cooled to room temperature, it is sieved to obtain quartz sand with a gradation particle size of 120 meshes for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com