Directionally arranged graphene super high heat conductivity composite material, and preparation method thereof

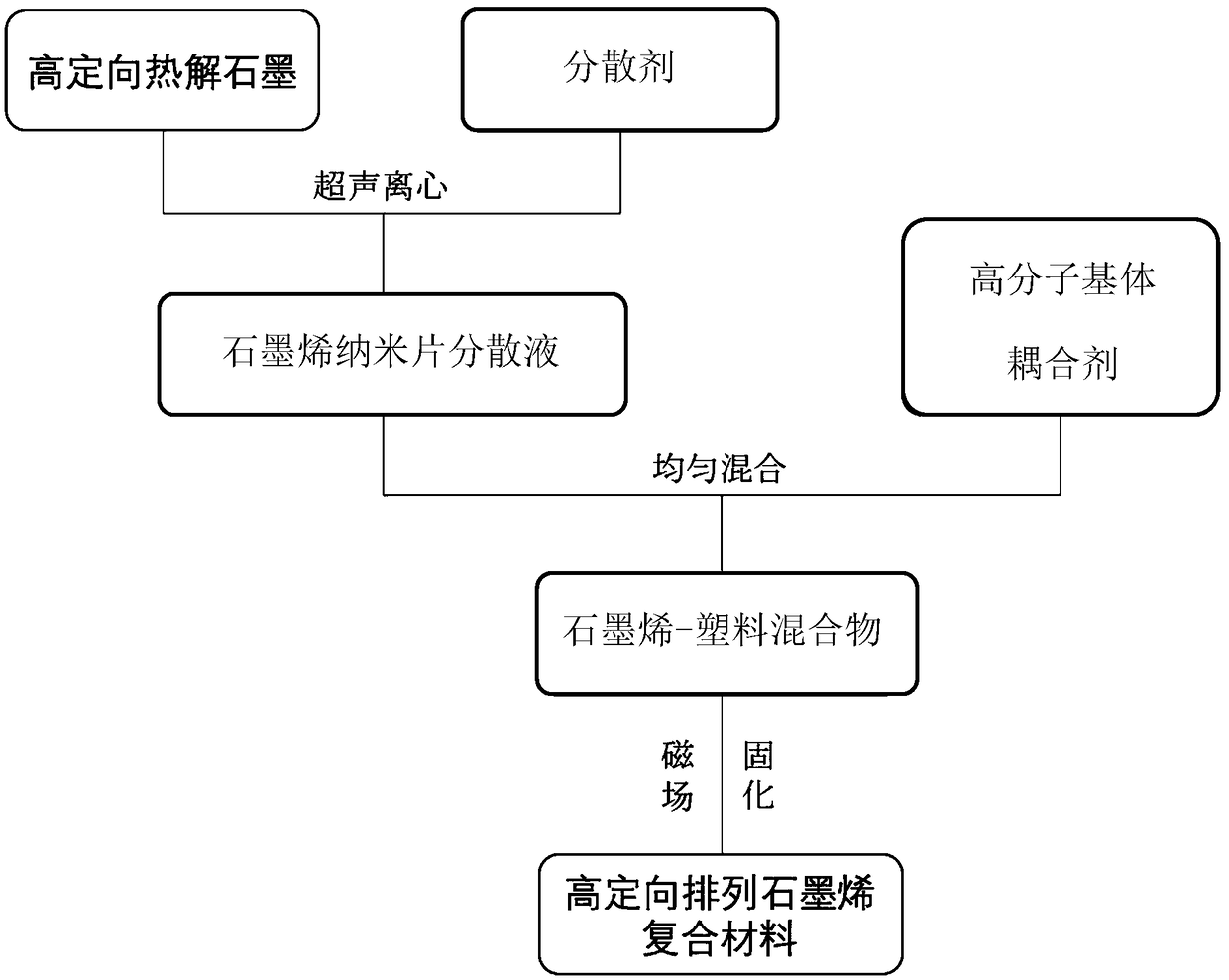

A composite material and directional arrangement technology, applied in the field of directional arrangement graphene ultra-high thermal conductivity composite material and its preparation, can solve the problems of low yield, offset thermal conductivity, inability to fully utilize the high thermal conductivity characteristics of graphene, etc. Simple method, strong controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

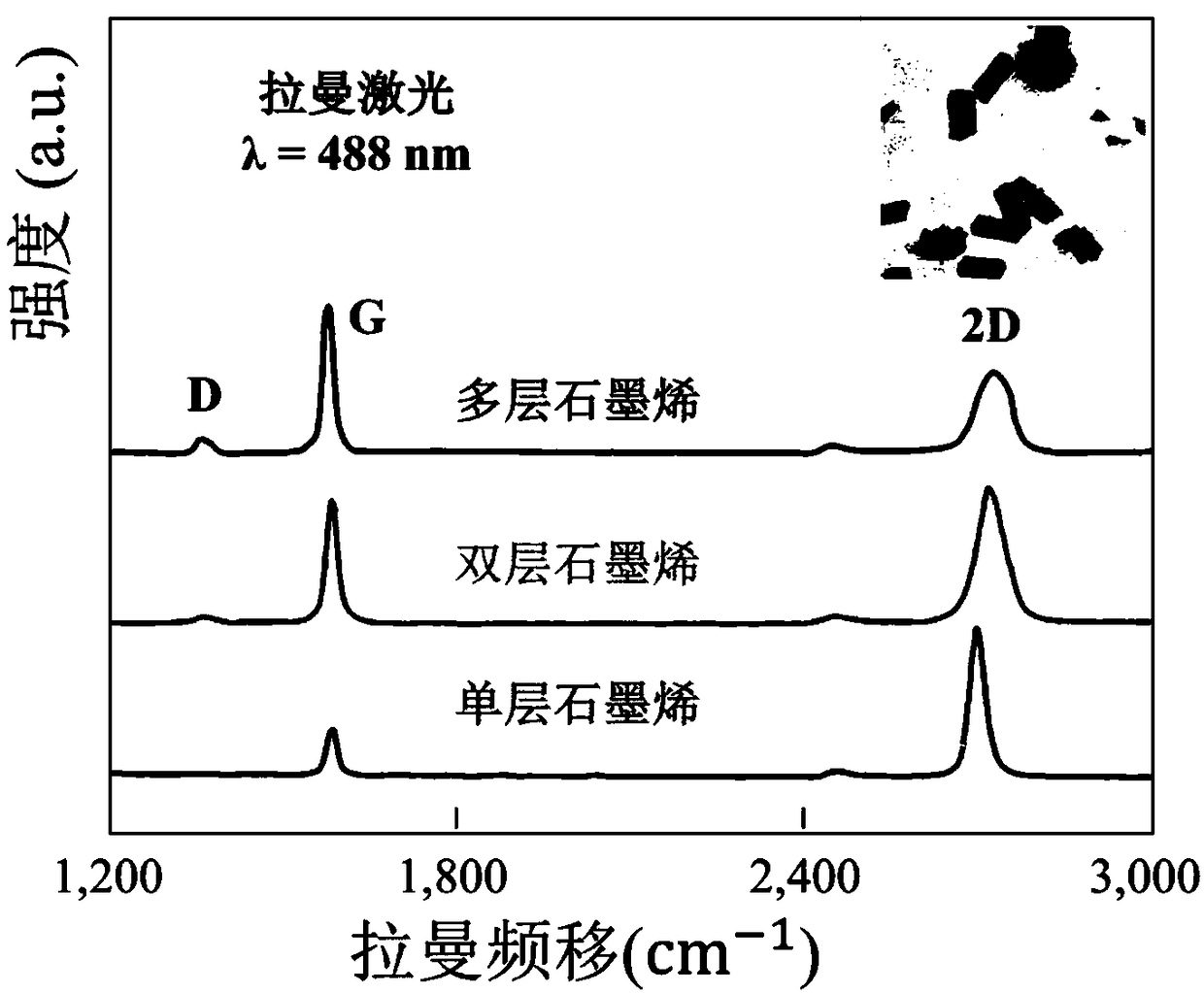

[0032] Disperse high-quality and highly oriented pyrolytic graphite in N-methylpyrrolidone, and use direct liquid phase exfoliation to prepare high-quality non-redox graphene nanosheets; the dispersion of graphene nanosheets is uniformly mixed with PE and polyvinylpyrrolidone Mix to form a graphene-plastic mixture; inject the mixture into a mold or a plastic device and apply a gradient magnetic field (1.5 Tesla), so that the graphene nanosheets are oriented and solidified. The mass fraction of the graphene nanosheets is 2.5%, the mass fraction of N-methylpyrrolidone is 15%, and the mass fraction of polyvinylpyrrolidone is 3%.

[0033] As a comparative example, the composition remains unchanged, and highly oriented pyrolytic graphite is dispersed in N-methylpyrrolidone, and non-redox graphene nanosheets are prepared by direct liquid phase exfoliation; the dispersion of graphene nanosheets is mixed with high The molecular matrix and polyvinylpyrrolidone are uniformly mixed to fo...

Embodiment 2

[0035] The massfraction of graphene nanoplate is 5%, all the other are with embodiment 1. The comparative examples were also set up.

Embodiment 3

[0037] The massfraction of graphene nanoplate is 7.5%, all the other are with embodiment 1. The comparative examples were also set up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com