Environment-friendly epoxy aqueous paint, and preparation method thereof

A technology of epoxy water-based coatings, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor environmental protection, poor comprehensive performance, and single functionality, and achieve good uniformity and stability , improve the effect of antibacterial, high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

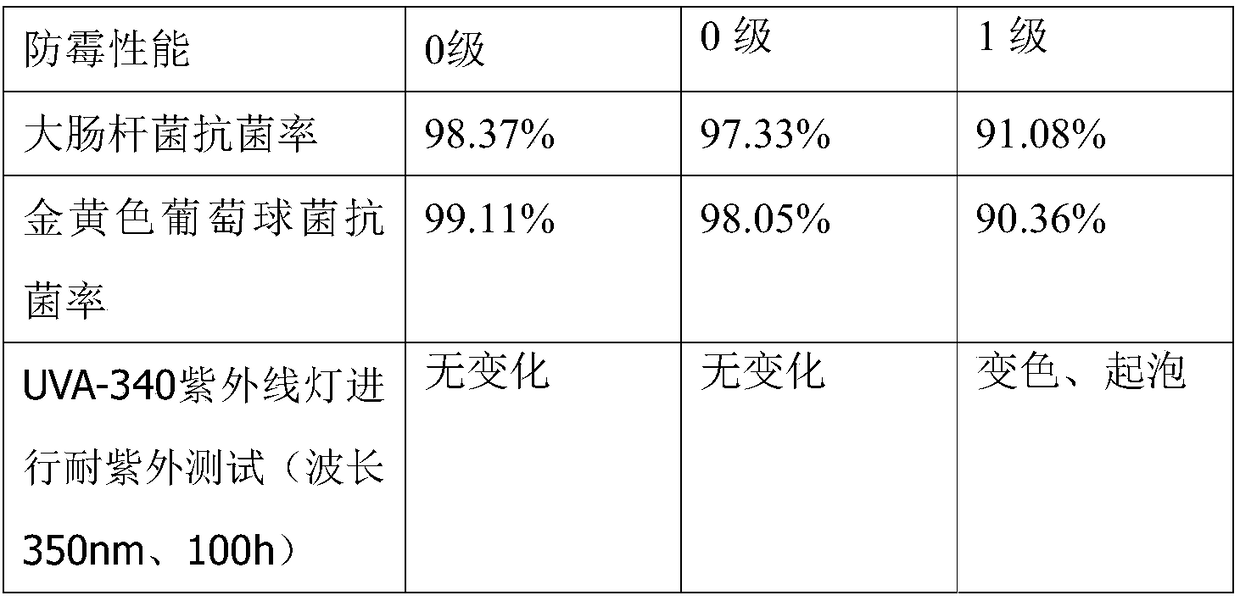

Embodiment 1

[0020] A kind of environment-friendly epoxy water-based coating, it is made up of the raw material of following weight part:

[0021] Water-based epoxy emulsion 200, sodium myristate soap 2, diisocyanate 3, methanol 40, tetrabutyl titanate 40.

[0022] Described aqueous epoxy emulsion is made up of the raw material of following weight part:

[0023] Epoxy resin E51 80, 1-methylimidazole 20, oleic acid 16, 2-mercaptobenzimidazole 2, sucrose acetate isobutyrate 1.

[0024] The preparation method of described aqueous epoxy emulsion, comprises the following steps:

[0025] (1) Take 2-mercaptobenzimidazole, add it to 9 times its weight in absolute ethanol, stir evenly, add 1-methylimidazole, keep stirring at 50°C for 2 hours, distill off ethanol, add oleic acid, Stir at room temperature for 4 hours to obtain oleate;

[0026] (2) Mix sucrose acetate isobutyrate and oleate, add deionized water 30 times the weight of the mixture, stir evenly, add epoxy resin E51, and ultrasonicate ...

Embodiment 2

[0032] A kind of environment-friendly epoxy water-based coating, it is made up of the raw material of following weight part:

[0033] Water-based epoxy emulsion 130, sodium myristate soap 1, diisocyanate 2, methanol 30, tetrabutyl titanate 30.

[0034] Described aqueous epoxy emulsion is made up of the raw material of following weight part:

[0035] Epoxy resin E51 70, 1-methylimidazole 18, oleic acid 10, 2-mercaptobenzimidazole 1, sucrose acetate isobutyrate 0.6.

[0036] The preparation method of described aqueous epoxy emulsion, comprises the following steps:

[0037] (1) Take 2-mercaptobenzimidazole, add it to 6 times the weight of absolute ethanol, stir evenly, add 1-methylimidazole, keep stirring at 40°C for 1 hour, distill off ethanol, add oleic acid, Stir at room temperature for 3 hours to obtain oleate;

[0038] (2) Mix sucrose acetate isobutyrate and oleate, add deionized water 20 times the weight of the mixture, stir well, add epoxy resin E51, and ultrasonicate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com