Preparation method of oil-soluble fluorescent tmds quantum dots and colloids thereof

A quantum dot and oil-soluble technology, applied in chemical instruments and methods, luminescent materials, nanotechnology, etc., can solve the problems of complex and unsafe preparation methods of oil-soluble fluorescent TMDs quantum dots, and achieve low equipment cost, simple method, The effect of mild and safe conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

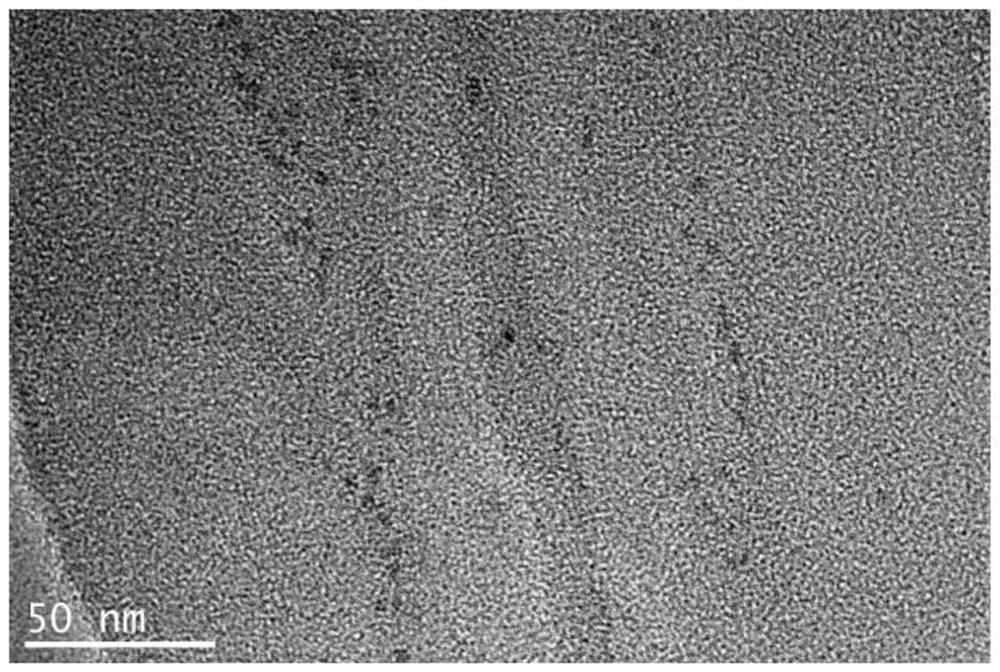

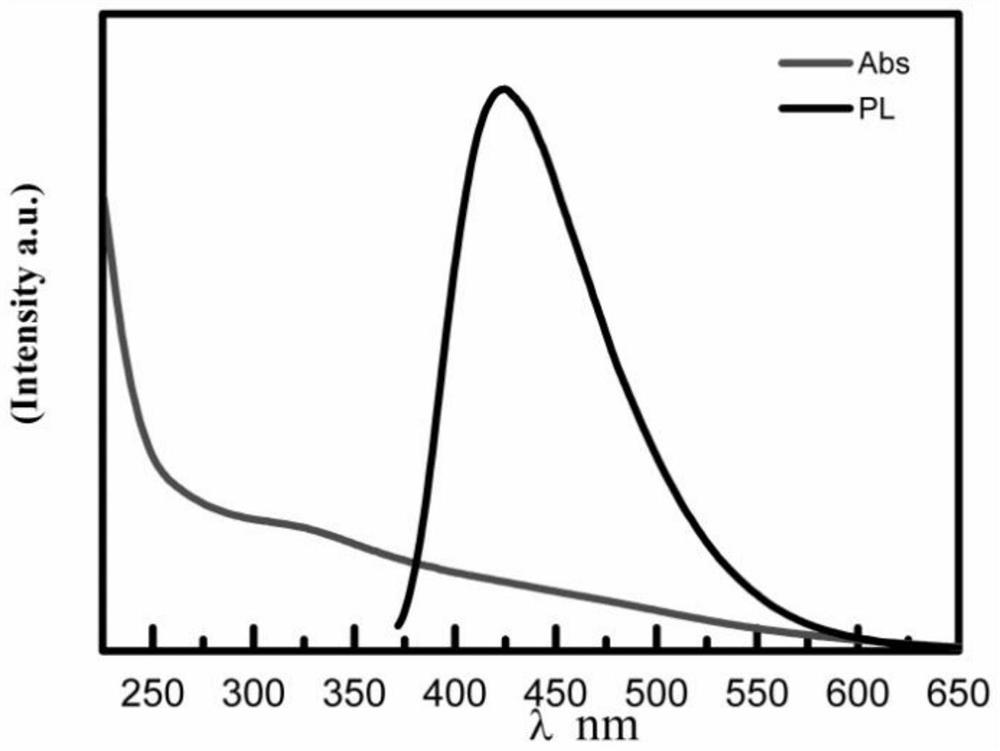

[0050] Example 1: Oil-soluble fluorescent MoS 2 Preparation of quantum dots

[0051] (1) Add 150mg MoS to a three-neck flask containing 30ml cyclohexanone 2 ;

[0052] (2) Simultaneously turn on the magnetic stirrer and the electric heating mantle, heat the solution under stirring conditions until the temperature of the solution is 140°C, then reflux at a constant temperature for 12 hours, then stop stirring, turn off the heat source at the same time, and let stand for 3 hours;

[0053] (3) Take the supernatant and centrifuge at 12000r / min for 10min, collect the supernatant and put it in a rotary evaporator, keep a relative vacuum of -40KPa, and dry it in vacuum at 120°C for 12 hours to obtain 50mg of fluorescent MoS 2 quantum dots. Calculated, fluorescent MoS 2 The yield of quantum dots was 0.33, and the fluorescence quantum yield was 9.6%.

[0054] Product yield calculation steps:

[0055] (1) Weigh the raw material MoS 2 or WS 2 mass, denoted as m 0 ;

[0056] (2)...

Embodiment 2

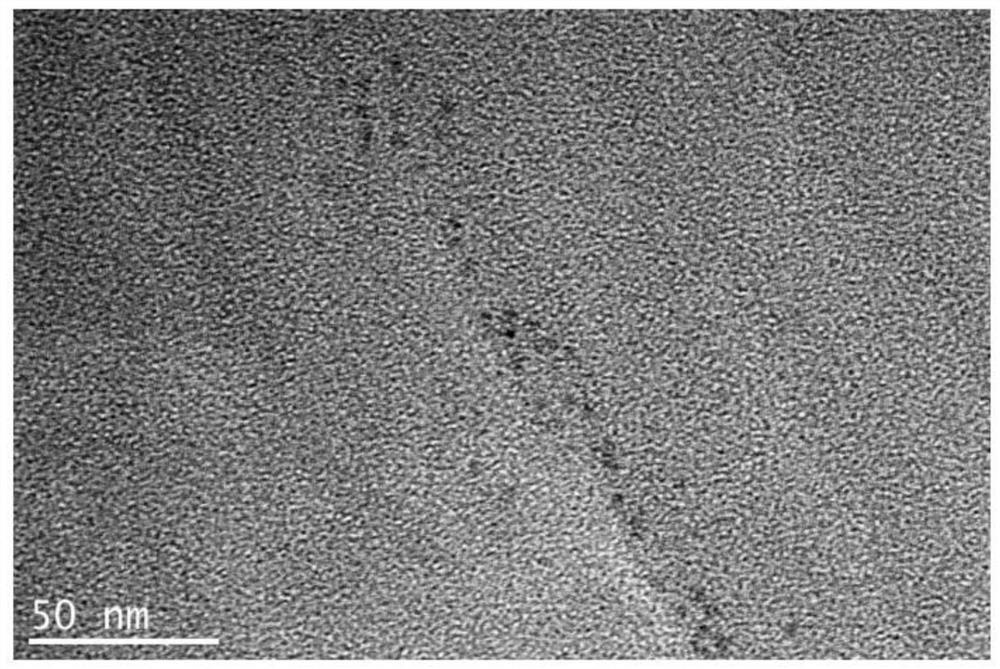

[0066] Example 2: Oil-soluble fluorescent MoS 2 Preparation of quantum dots

[0067] Using the method of Example 1, the difference is that in the present example step (1) cyclohexanone and MoS 2 The dosages are 60ml and 400mg respectively. This embodiment obtains 120mg fluorescent MoS in total 2 quantum dots. Calculated, fluorescent MoS 2 The yield of quantum dots is 0.3, and the fluorescence quantum yield is 8.8%.

Embodiment 3

[0068] Example 3: Oil-soluble fluorescent MoS 2 Preparation of Quantum Dot Colloids

[0069] Get the MoS prepared in 20mg embodiment 1 2 Quantum dots, added to 20ml cyclohexane, ultrasonically dispersed for 20min, stored at low temperature and protected from light, to obtain fluorescent MoS 2 Quantum dot colloid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com