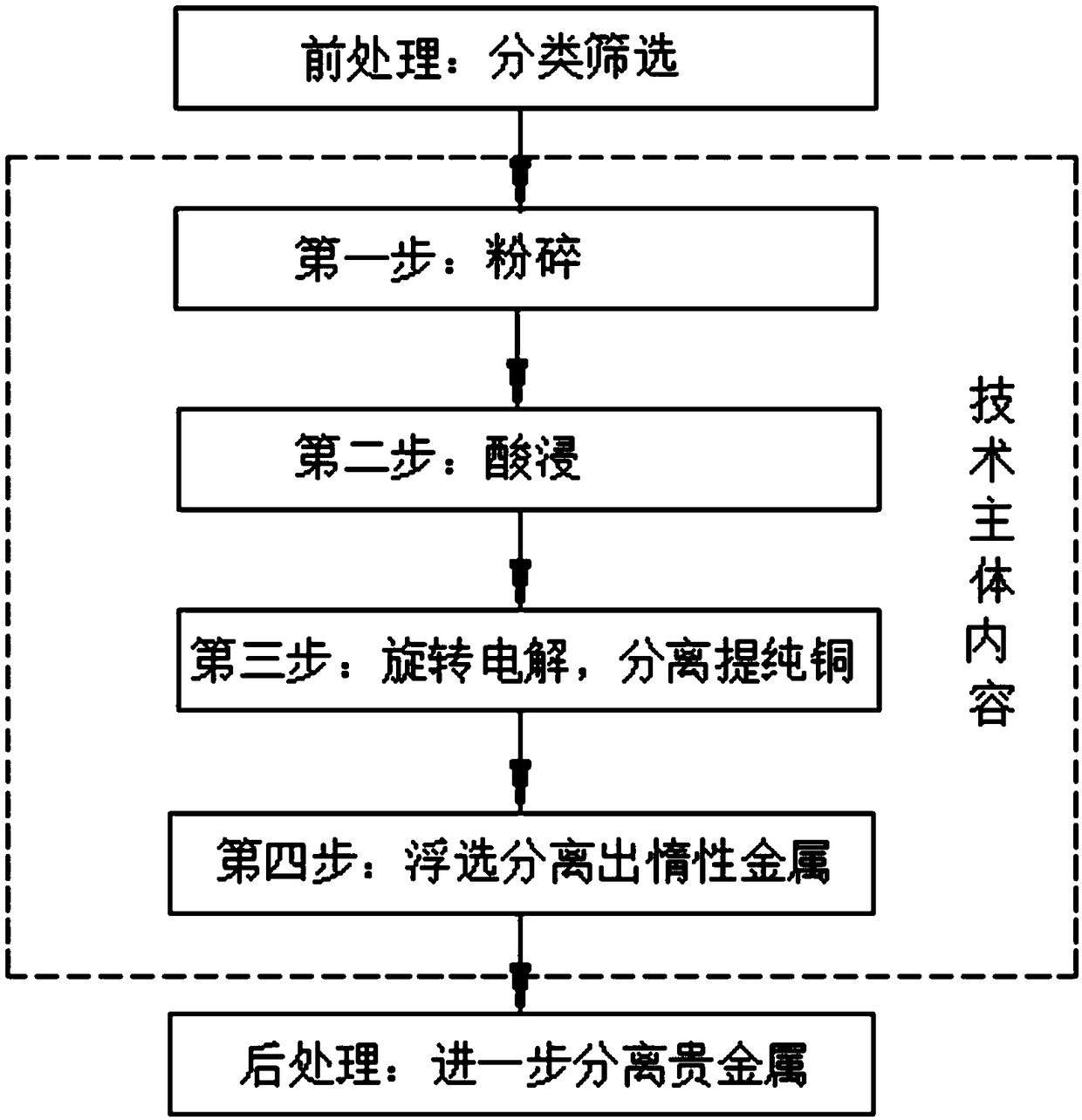

Method of recovering metals in circuit boards in classified manner

A technology of circuit boards and metals, which is applied in the field of metal classification and recycling circuit boards, to avoid operational hazards, improve product purity, and avoid pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 10kg of waste PCB boards whose surface process is chemical immersion gold. Use a cyclone pulverizer to pulverize and pass through a 50-mesh sieve, and the coarse particles continue to pulverize to pass through the sieve and transfer to 20L of H2O with a concentration of 1mol / L. 2 SO 4 After soaking in the solution for 24 hours, dissolve and leach nickel and tin into the solution, and filter to obtain a mixed solution of nickel sulfate and tin sulfate; the filter residue is transferred to the rotating electrolysis anode group and connected to the positive pole of the power supply, and the negative pole is connected to the arc-shaped stainless steel plate. The electrolyte consists of 3 mol / L CuSO 4 , 1 mol / L H 2 SO 4 and 0.01g / L Mn(SO 4 ) 2 Composition, the center distance between the anode group and the corresponding cathode steel plate is controlled to be 15cm, the minimum distance is 5cm, the electrolysis is carried out at a constant voltage of 10V, and the ...

Embodiment 2

[0040] Weigh 10kg of waste PCB boards whose surface process is OSP. Use a mechanical pulverizer to pulverize and pass through a 50-mesh sieve, and the coarse particles continue to be pulverized to pass through the sieve; transfer to 20 L of H 2 SO 4 After soaking in the solution for 24 hours, dissolve and leach nickel and tin into the solution, and filter to obtain a mixed solution of nickel sulfate and tin sulfate; The electrolyte consists of 1mol / L CuSO 4 , 3mol / LH 2 SO 4 and 0.01g / L Fe 2 (SO 4 ) 3 Composition, the center distance between the anode group and the corresponding cathode steel plate is controlled to be 15cm, the minimum distance is 5cm, the electrolysis is carried out at a constant voltage of 10V, the mixer is turned on at the same time during electrolysis, the rotation speed is 600 r / min, and air is blown at the bottom, After 5 hours of electrolysis, 0.59 kg of copper was recovered at the cathode, and resin powder and metal slime were collected in the anod...

Embodiment 3

[0042] The surface process is a mixture of waste PCB boards with chemical immersion gold and OSP, weighing 10Kg. And pass through the sieve screen of 50 meshes, coarse particles continue to pulverize, to pass through the sieve screen; 2 SO 4 After soaking in the solution for 24 hours, dissolve and leach nickel and tin into the solution, and filter to obtain a mixed solution of nickel sulfate and tin sulfate; The electrolyte consists of 4mol / L CuSO 4 , 3mol / L H 2 SO 4 and 0.01g / L Fe 2 (SO 4 ) 3 Composition, the center distance between the anode group and the corresponding cathode steel plate is controlled to be 15cm, the minimum distance is 5cm, the electrolysis is carried out at a constant voltage of 10V, the mixer is turned on at the same time during electrolysis, the rotation speed is 600 r / min, and air is blown at the bottom, After 5 hours of electrolysis, 0.64 kg of copper was recovered at the cathode, and resin powder and metal slime were collected in the anode fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com