Method for dyeing fabric with color-matched natural pigment

A fabric dyeing and natural pigment technology, applied in the field of fabric dyeing with natural pigments, can solve the problems of not being able to adapt to the temperature during printing and dyeing, and achieve the effects of low space and environmental requirements, bright colors, good color yield and color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

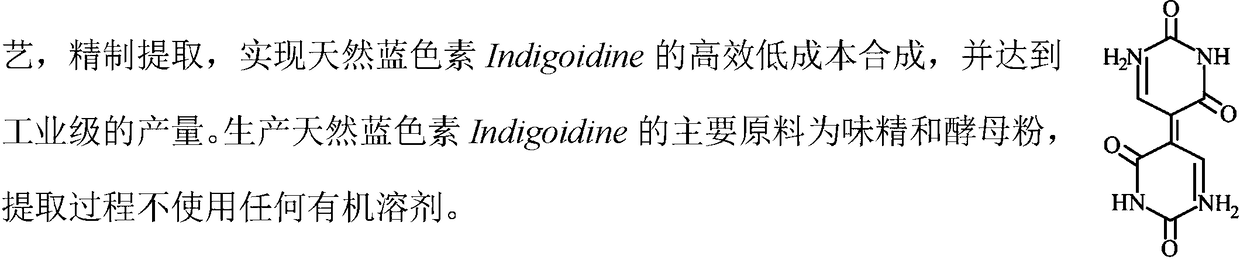

[0025] A method for dyeing fabrics with natural pigments after color matching,

[0026] The natural blue pigment Indigoidine and Monascus red pigment are dissolved in the solvent respectively and then mixed for color matching; together with praseodymium chloride, they are added to the water, the pH value is adjusted to 3, the fabric is added to the dyeing solution, and the temperature is raised to 60°C for dyeing. After washing and drying, the dyeing of the fabric is completed; the mass percentage of praseodymium chloride is 5-10g / L.

[0027] The mass fraction of natural blue pigment Indigoidine is at most 30%. The solvent is water.

Embodiment 2

[0029] A method for dyeing fabrics with natural pigments after color matching,

[0030] The natural blue pigments Indigoidine and Monascus Yellow are dissolved in solvents and then mixed for color matching; they are added to water together with lanthanum trioxide, the pH value is adjusted to 6, the fabric is added to the dyeing solution, and the temperature is raised to 90°C for dyeing , washed with water and dried to complete the dyeing of the fabric; the sum of the mass percentages of lanthanum trioxide is 10g / L.

[0031] The mass fraction of natural blue pigment Indigoidine is at most 30%. The fabric is silk fabric. The solvent is alcohol.

Embodiment 3

[0033] A method for dyeing fabrics with natural pigments after color matching,

[0034] The natural blue pigment Indigoidine, Monascus red pigment and Monascus yellow pigment are dissolved in the solvent respectively and then mixed for color matching; together with sodium sulfonate, they are added to the water, the pH value is adjusted to 4, the fabric is added to the dyeing solution, and the temperature is raised Dyeing at 68°C, washing and drying to complete the dyeing of the fabric; the sum of the mass percentages of sodium sulfonate is 8g / L.

[0035] The mass fraction of natural blue pigment Indigoidine is at most 30%. The fabric is wool fabric. The solvent is methanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com