High-temperature mine cold and heat source utilization system and operation mode based on absorption type heat pump

An absorption heat pump and heat source technology, applied in the heat source utilization system and high-temperature mine cooling field, can solve the problems of endangering the physical and mental health and life safety of employees, restricting the promotion of conventional mine cooling technology, and low resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

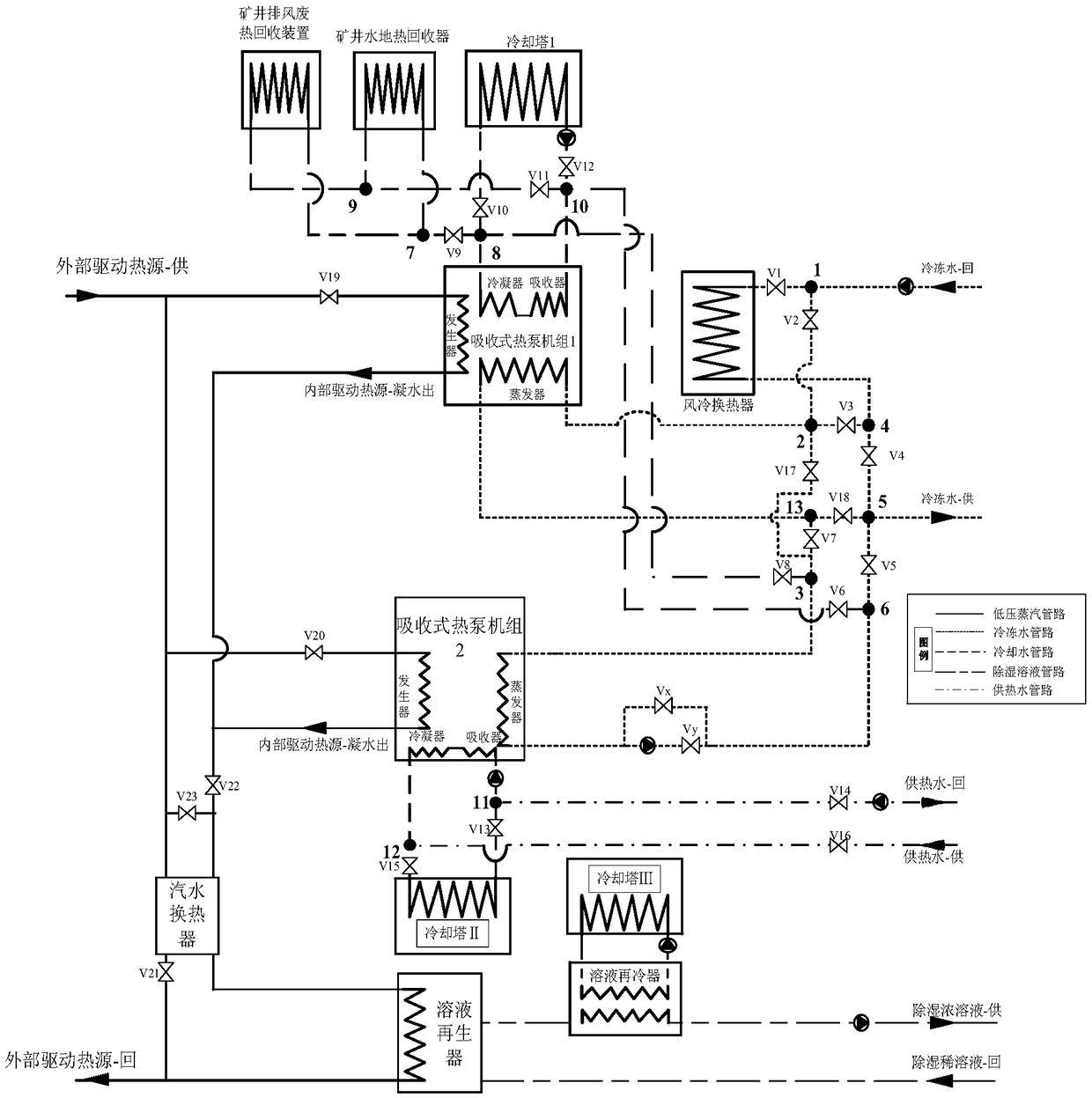

[0063] Example 1, such as figure 1 as shown,

[0064] (1) When the outdoor temperature t≥12°C, the heat pump unit is used to produce chilled water. The specific process is as follows:

[0065] There are two operation methods for the driving heat source pipeline system: the first one, when the external driving heat source is not needed, the V21 valve is closed, the V19 valve, V20 valve, V22 valve, and V23 valve are opened, and the external driving heat source enters the first absorption type respectively. Heat pump unit 1 and the second absorption heat pump unit 2, in the two absorption heat pump units, the condensed water (internal driving heat source) after heat release and cooling drives the solution regenerator, and the V20 valve is closed only when the first absorption heat pump unit 1 is turned on , when only the second absorption heat pump unit 2 is turned on, the V19 valve is closed; the second type, when an external driving heat source is needed, the V19 valve, V20 va...

Embodiment 2

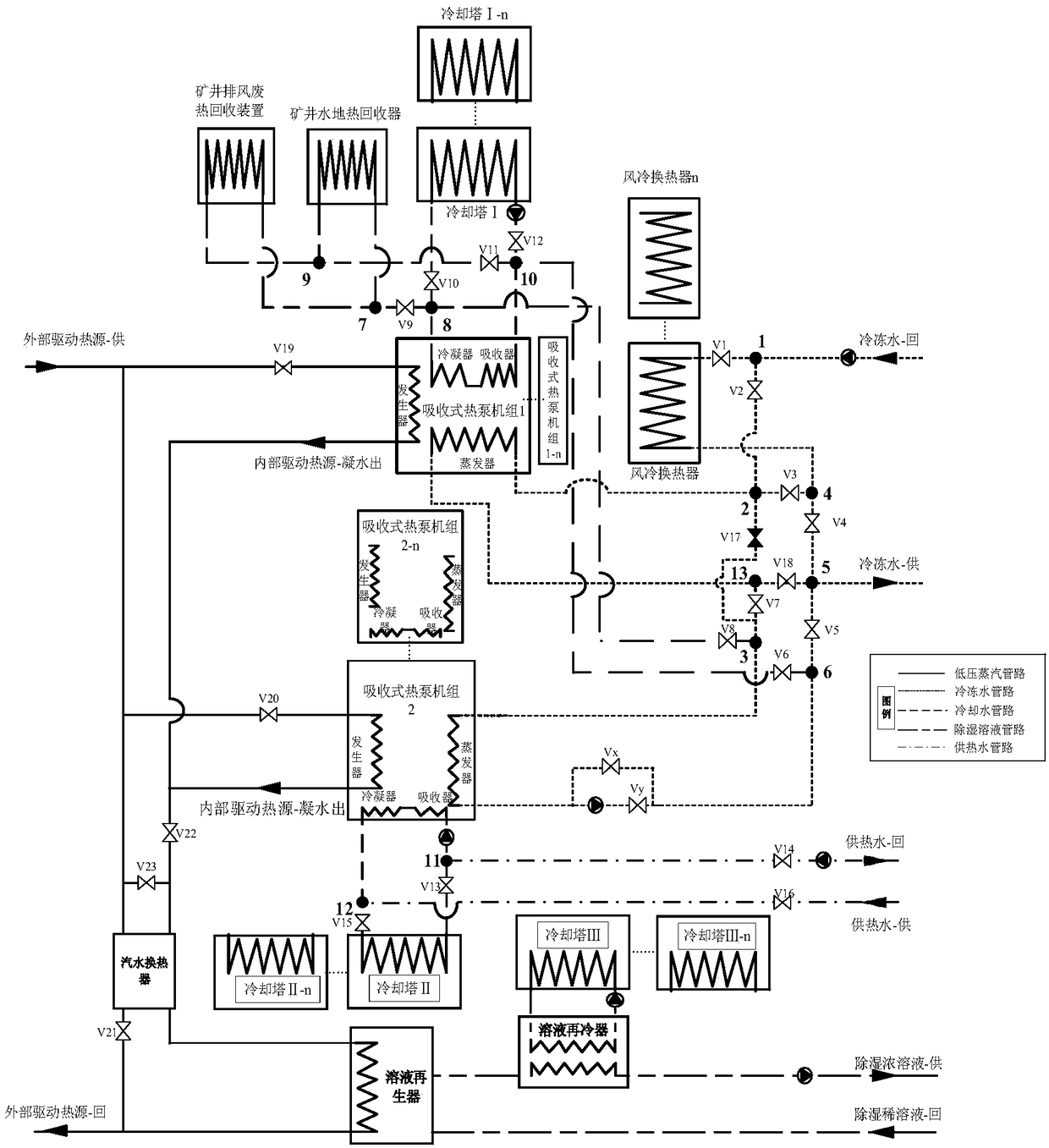

[0094] Such as figure 2As shown, on the basis of the disclosure of Example 1, according to the cooling load demand, the air-cooled heat exchanger, the first absorption heat pump unit 1, the second absorption heat pump unit 2, the first cooling tower I and the second cooling tower Ⅱ One or more units are operated in series or in parallel. Among them, there are two operation methods for driving the heat source pipeline system: the first one, when the external drive heat source is not needed for thermal assistance, the V21 valve is closed, and the V19 valve, V20 valve, and V22 valve are closed. , V23 valve is opened, the external driving heat source enters the first absorption heat pump unit 1 and the second absorption heat pump unit 2 respectively, and the condensed water (internal driving heat source) in the two absorption heat pump units drives the solution regenerator , when only the first absorption heat pump unit 1 is turned on, the V20 valve is closed, and when the second...

Embodiment 3

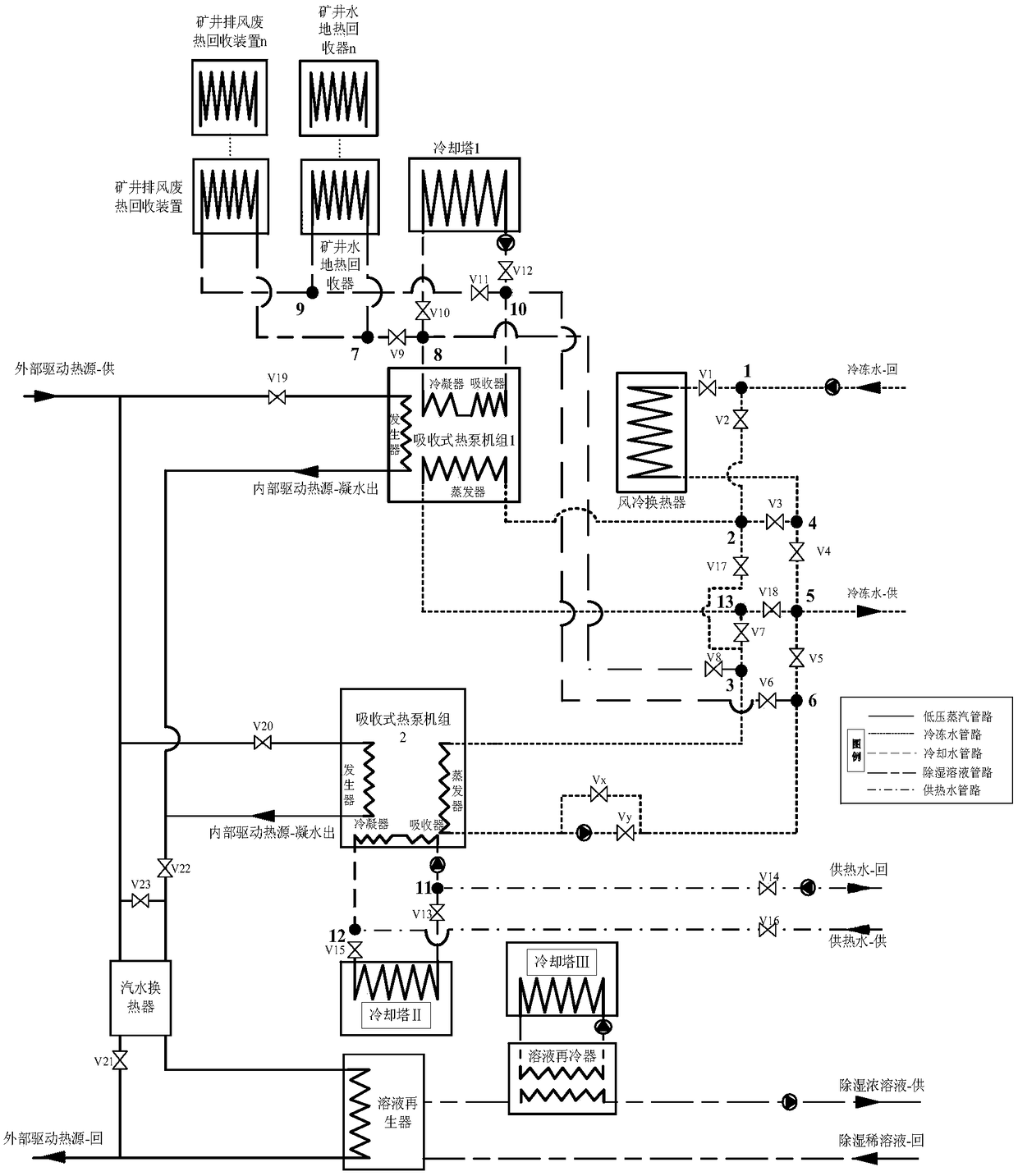

[0119] Such as image 3 As shown, on the basis of the disclosure in Embodiment 1, one or more mine exhaust exhaust heat recovery devices and mine water geothermal heat recovery devices can be operated in series or in parallel according to the heat load demand. There are two operation methods for the driving heat source pipeline system: the first one, when the external driving heat source is not needed, the V21 valve is closed, the V19 valve, V20 valve, V22 valve, and V23 valve are opened, and the external driving heat source enters the first absorption type respectively. Heat pump unit 1 and the second absorption heat pump unit 2, in the two absorption heat pump units, the condensed water (internal driving heat source) after heat release and cooling drives the solution regenerator, and the V20 valve is closed only when the first absorption heat pump unit 1 is turned on , when only the second absorption heat pump unit 2 is turned on, the V19 valve is closed; the second type, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com