Low energy consumption denitration system for sintering smoke and technology

A technology of sintering flue gas and low energy consumption, applied in the field of sintering flue gas treatment, can solve the problems of unconsidered energy consumption, insufficient consideration, and large energy consumption, so as to ensure reliable operation of the system, reduce injection volume, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

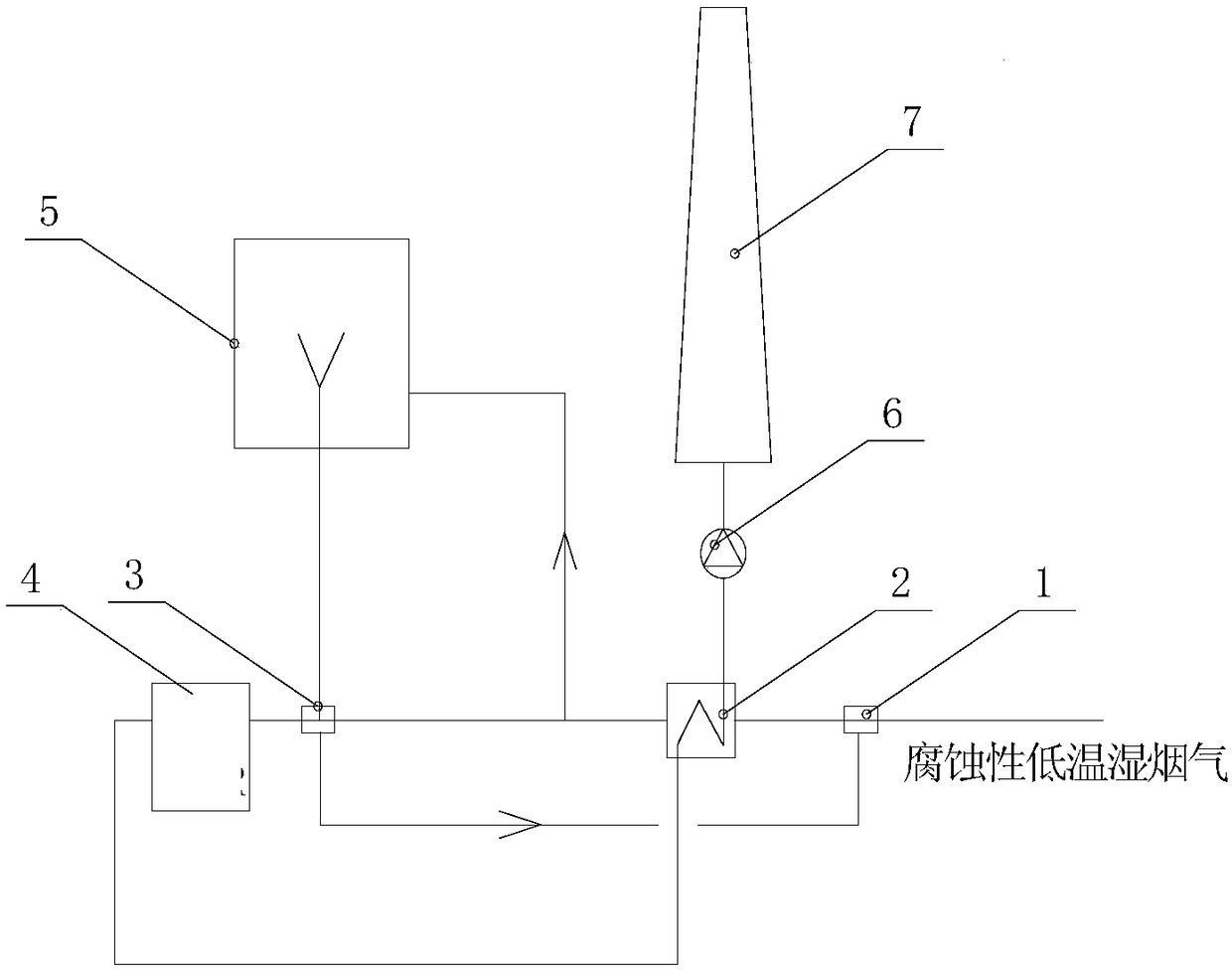

[0047] This embodiment provides a low energy consumption sintering flue gas denitrification system, the structural diagram of the system is as follows figure 1 shown, from figure 1 It can be seen from the figure that the system includes a primary heating device 1, a flue gas heating heat exchanger 2, a secondary heating device 3, a denitrification device 4, a hot flue gas generating device 5, a pressurized fan 6 and a chimney 7;

[0048] The primary heating device 1 is provided with a first flue gas inlet, a second flue gas inlet, and a flue gas outlet; The flue gas outlet of the device 1 passes through the flue gas heating heat exchanger 2 (the first flue gas inlet and the first flue gas outlet) and the secondary heating device 3 (the first flue gas inlet and the first flue gas outlet) in sequence through the pipeline It is connected with the flue gas inlet of the denitrification device 4; the flue gas outlet of the denitrification device 4 is connected with the second flue ...

Embodiment 2

[0053] This embodiment provides a low-energy sintering flue gas denitrification process, wherein the process is realized by using the low-energy sintering flue gas denitrification system provided in Example 1, and the process includes the following specific steps:

[0054] (1) Sintering flue gas (such as low-temperature wet sintering flue gas containing acid corrosive gas) enters the primary heating device 1 through the pipeline through its first flue gas inlet, and is initially heated in the primary heating device 1 The sintering flue gas is used to remove moisture in the flue gas and avoid acid corrosion;

[0055] (2) Exchange heat between the high-temperature purified flue gas obtained after the denitrification treatment and the sintered flue gas obtained in step (1) in the flue gas heating heat exchanger 2, so that the sintered flue gas is heated to about 150 ° C again, and then cooled The final high-temperature purified flue gas (its temperature is about 110°C) is dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com