Au@Cu2O composite hollow micro-particles, preparation method and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

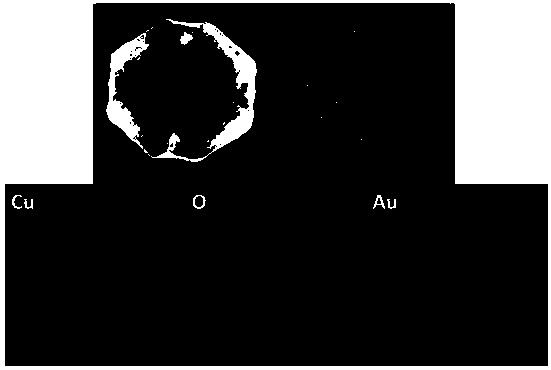

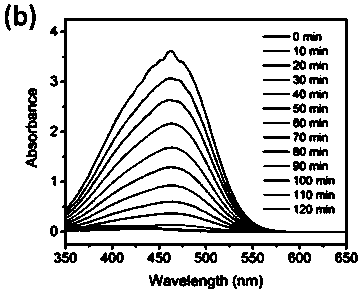

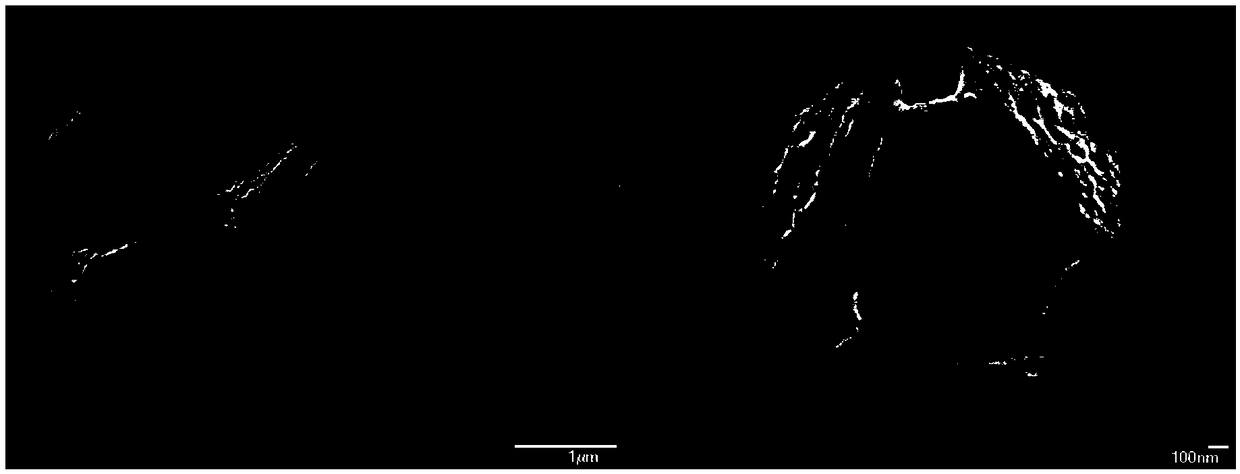

[0025] The following will be combined with Figure 1-4(b) The embodiment of the present invention is described in detail. One embodiment of the present invention is Au@Cu 2 The preparation method of O composite hollow micron particle, comprises the steps:

[0026] Step (1), preparing a hollow Cu shell;

[0027] And, in step (2), add chloroauric acid solution to obtain Au@Cu 2 O composite hollow micron particles.

[0028] Further, in step (1), preparing the hollow Cu shell includes:

[0029] In step (1-1), an alkaline solution is added to a certain concentration of copper salt solution, and then a reducing agent is added to make Cu 2+ reduced to Cu + , to obtain cuprous oxide;

[0030] Step (1-2), the cuprous oxide obtained in step (1) is put into the ethylene glycol solution, and the alkaline solution and the above-mentioned reducing agent are added successively, the cuprous oxide is reduced by the reducing agent, and the Cu + reduced to Cu 0 , to obtain hollow Cu shel...

Embodiment 1

[0042] (1) Add 25ml of sodium hydroxide solution (3.6M) dropwise into 30ml of copper sulfate solution (0.1M), and then add 0.5g of hydroquinone powder after 5 minutes. The entire reaction temperature is kept at 55°C. 2+ reduced to Cu + , reacted for 60 minutes to obtain a 26-hedral cuprous oxide.

[0043] (2) Disperse the cuprous oxide of 26-hedron in 180ml ethylene glycol solution, add 60ml of sodium hydroxide solution (5M), then add 60ml of glucose solution (1.1M), the whole reaction temperature remains at 60°C, and Cu + reduced to Cu 0 , and reacted for 180 minutes to obtain a hollow Cu shell.

[0044] (3) Put the hollow Cu shell into 90ml of aqueous solution containing 0.3g of PVP, add 9ml of chloroauric acid solution (10mM), stir and react at 550rpm at room temperature for 60 minutes at 23°C, centrifuge at 7000rpm for 2 minutes to collect and dry The obtained powder can obtain hexahedron Au@Cu with a hollow structure 2 O composite microparticles.

[0045] The result...

Embodiment 2

[0048] (1) Add 25ml of sodium hydroxide solution (6.8M) dropwise into 30ml of copper sulfate solution (0.1M), and then add 0.5g of hydroquinone powder after 5 minutes. The entire reaction temperature is kept at 55°C. 2+ reduced to Cu + , reacted for 60 minutes to obtain an octahedral cuprous oxide.

[0049] (2) Disperse the octahedral cuprous oxide in 180ml ethylene glycol solution, add 60ml of sodium hydroxide solution (5M), then add 60ml of glucose solution (1.1M), the whole reaction temperature remains at 60°C, and Cu + reduced to Cu 0 , and reacted for 180 minutes to obtain a hollow Cu shell.

[0050] (3) Put the hollow Cu shell into 90ml of aqueous solution containing 0.3g of PVP, add 9ml of chloroauric acid solution (10mM), stir and react at 550rpm at room temperature for 60 minutes at 23°C, centrifuge at 7000rpm for 2 minutes to collect and dry The obtained powder can obtain octahedral Au@Cu with a hollow structure 2 O composite microparticles.

[0051] The result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com