A kind of nicuzn gyromagnetic ferrite material for ltcc circulator and preparation method thereof

A technology of gyromagnetic ferrite and circulator, applied in the field of NiCuZn gyromagnetic ferrite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

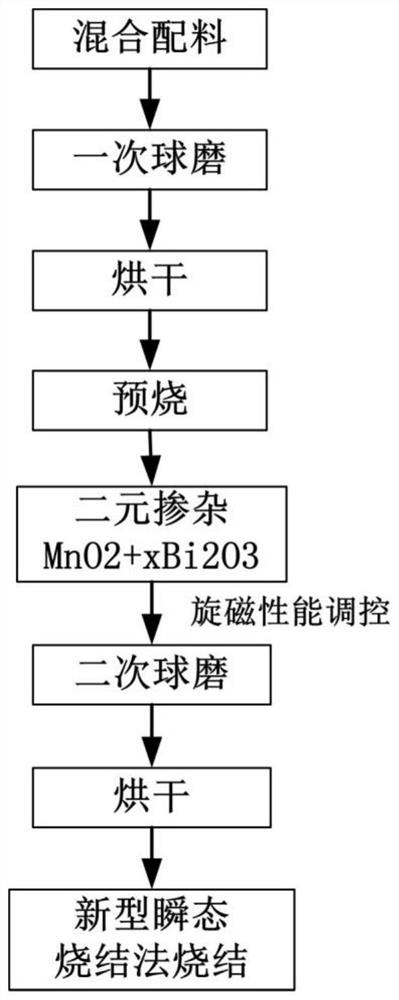

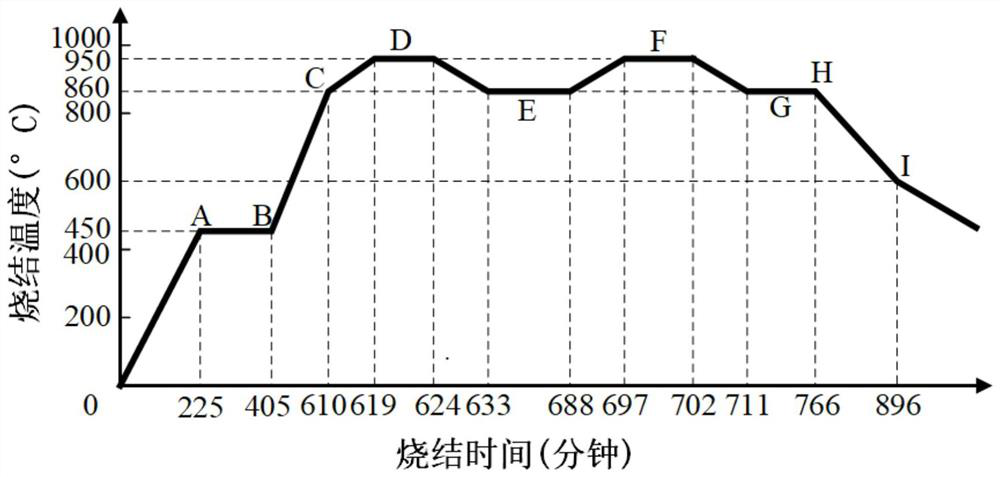

[0035] A kind of preparation method of the NiCuZn gyromagnetic ferrite material that is used for LTCC circulator, comprises the following steps:

[0036] Step 1: NiO, CuO, ZnO and Fe 2 o 3 As raw material, according to the molecular formula Ni 0.2 Cu 0.2 Zn 0.6 Fe 2 o 4 NiO, CuO, ZnO and Fe were converted from the ratio of metal elements in 2 o 3 mass percentage, carry out weighing and mixing, and once ball mill for 10 hours, the raw materials are fully mixed to obtain the mixed powder after the first ball mill;

[0037] Step 2: Put the mixed powder after primary ball milling obtained in Step 1 in an oven, dry it at a temperature of 120°C, and then put it into a sintering furnace for the first pre-sintering, the pre-sintering temperature is 820°C, and the time is After 3 hours, cool down to room temperature with the furnace to obtain the pre-fired powder after the first pre-fire;

[0038] Step 3: Add 0.5wt% MnO equivalent to the mass of the powder in the calcined powder...

example 1

[0070] A kind of preparation method of the NiCuZn gyromagnetic ferrite material that is used for LTCC circulator, comprises the following steps:

[0071] Step 1: NiO (purity is 99%,), CuO (purity is 99%), ZnO (purity is 99%) and Fe 2 o 3 (purity is 99%) as raw material, according to the chemical formula Ni 0.2 Cu 0.2 Zn 0.6 Fe 2 o 4 Carry out weighing, mixing, configuration obtains main powder, the main powder that configuration obtains is according to mass ratio main powder: deionized water: the ratio of zirconium ball=1:1:2.5 carries out ball mill once, ball milling time is 12h, The rotating speed of the ball mill is 300r / min, so that it is fully mixed evenly, and the mixed powder after the first ball mill is obtained;

[0072] Step 2: Put the mixed powder after primary ball milling obtained in Step 1 in an oven, dry it at a temperature of 120°C, and then put it into a sintering furnace for the first pre-sintering, the pre-sintering temperature is 820°C, and the time i...

Embodiment 1

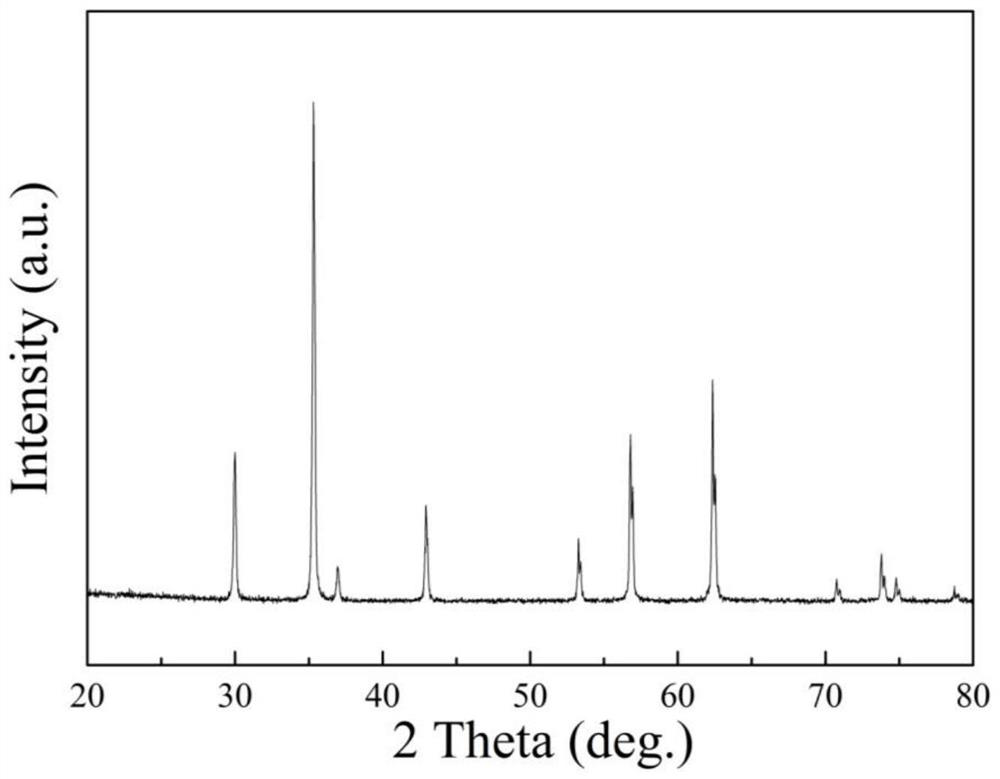

[0088] The properties of the NiCuZn gyromagnetic ferrite material used in LTCC circulators prepared in Example 1 are: sample density: 4.919g / cm 3 , the saturation magnetization is 50.01emu / g, the ferromagnetic resonance linewidth is 491.7Oe, and the coercive force is 347.73A / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com