Laminate of aramid paper sheet and polyimide film and method for producing same

A technology of polyimide film and manufacturing method, applied in chemical instruments and methods, paper/cardboard layered products, papermaking, etc., can solve problems such as being unsuitable for continuous processing of large sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (raw material preparation)

[0062] A fibrid body of poly-m-phenylene isophthalamide was produced using a pulp particle production apparatus (wet-type precipitator) constituted by a combination of a stator and a rotor described in JP-A-52-15621. This was processed in a mill, beater to adjust the length-weighted average fiber length to 0.9 mm. On the other hand, meta-aramid fiber (meta-aramid fiber, NOMEX (registered trademark), monofilament fineness: 2.2 dtex) manufactured by DuPont was cut to a length of 6 mm, and used as a raw material for papermaking.

[0063] (Manufacture of aramid paper)

[0064] The above-prepared aramid fibrids and aramid short fibers were each dispersed in water to prepare a slurry. These slurries are mixed so that the aramid fibrids and aramid short fibers have a mixing ratio (weight ratio) of 1 / 1, and then the liquid is sent to a fourdrinier type paper machine for dehydration , squeezed water, dried and coiled to obtain aramid paper.

[00...

Embodiment 2

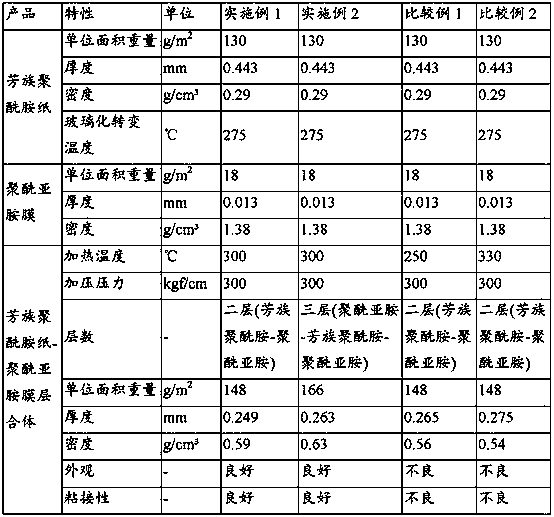

[0076] The aramid paper and two polyimide films obtained in Example 1 were cut into A4 size, and laminated with the aramid paper sandwiched between the two polyimide films to prepare Prelaminate. Using a calendering device with metal calender rolls, the prelaminate was subjected to heat and pressure processing at a temperature of 300°C and a linear pressure of 300kgf / cm to obtain a polyimide film-aromatic polyamide film. Three-layer laminate of amide paper-polyimide film. The main characteristic values of the insulating member thus obtained were evaluated in the same manner as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com