Larimichthys crocea feed and preparation method thereof

A technology for large yellow croaker and feed, which is applied in the direction of animal feed, animal feed, and animal feed molding or processing, can solve the problems of extruded material absorbing water, waste of feed, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

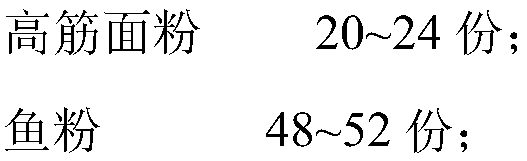

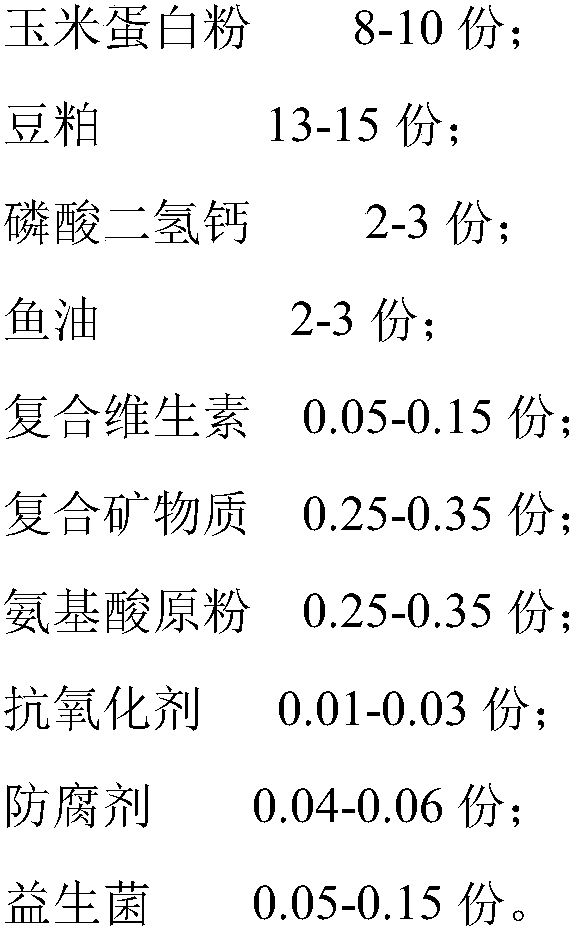

Method used

Image

Examples

Embodiment 1a

[0047] A preparation method for large yellow croaker feed, comprising the following steps:

[0048] Step1, use a feed mill to grind 20kg of high-gluten flour, 48kg of fish meal, 8kg of corn gluten meal, 13kg of soybean meal, 2kg of calcium dihydrogen phosphate, 0.05kg of multivitamin, 0.25kg of multivitamin, 0.25kg of raw amino acid powder, and 0.05kg of probiotics After pulverizing and stirring evenly, pass through a 100-mesh sieve to obtain the mixture;

[0049] Step2, put the pulverized mixture into a differential pressure extruder for pre-expansion to obtain a pre-expanded material;

[0050] Step3, mix 2kg of fish oil, 0.01kg of antioxidant, and 0.04kg of preservative evenly, then add it to the pre-expanded material, stir evenly and dry it to obtain the dried material;

[0051] Step4, putting the dried material into the differential pressure extruder again for extruding to obtain the large yellow croaker feed.

[0052] Multivitamins were purchased from Jinan Hongtu Chemi...

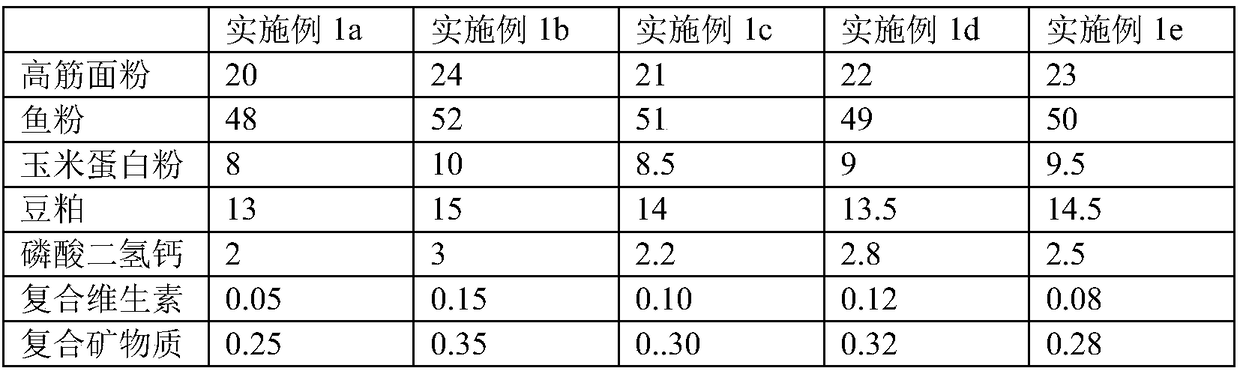

Embodiment 1

[0059] The preparation method of Example 1b-Example 1e is the same as that of Example 1a, the difference is that the components and the specific content of the components of Example 1b-Example 1e are different from Example 1a. See the table below for details (unit: kg):

[0060]

[0061]

Embodiment 2a

[0063] A preparation method for large yellow croaker feed, comprising the steps of:

[0064] Step1, dissolve 0.3kg of cornstarch, 0.2kg of propolis, 0.1kg of guar gum, 0.05kg of lotus leaf powder, and 0.02kg of sodium carboxymethyl cellulose in 10kg of water and stir to obtain a thick liquid;

[0065] Step2, use the feed obtained in Example 1a as the puffed body, spray the viscous liquid on the surface of the puffed body, the nozzle diameter is 0.1mm, the nozzle pressure is 10Mpa, and after blast drying at 50°C, a rough polysaccharide layer with a thickness of 0.1mm is obtained ;

[0066] Step3, after drying 0.5kg of beeswax at 50°C with air blast, mix it with 2L of water and pulverize it evenly with an ultrafine pulverizer to obtain a micron-sized edible wax suspension;

[0067] Step4, take part of the micron edible wax suspension and add it to the nano grinder to continue grinding evenly to obtain the nano edible wax suspension;

[0068] Step5, after mixing the nano-scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com