Formula and production process of purple sweet potato-flavored puree

A production process and technology of purple sweet potato, applied in the field of purple sweet potato flavor puree formula and production process, can solve the problems of anti-corrosion and difficulty in maintaining the product state, and achieve the effects of promoting gastrointestinal motility, stable product state, and good water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

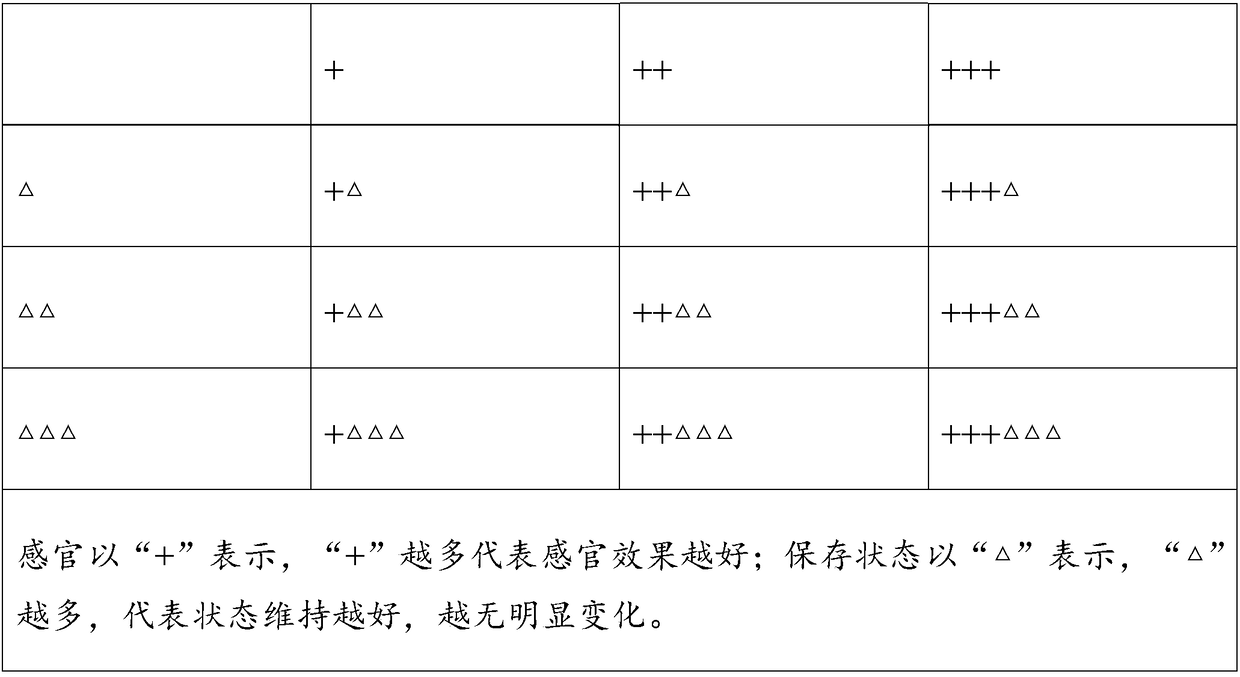

Image

Examples

Embodiment 1

[0019] A purple sweet potato puree, which is composed of the following components by mass percentage: purple sweet potato 33%, white granulated sugar 34%, 75-degree maltose syrup 13%, sodium carboxymethyl cellulose 0.2%, modified starch 0.4%, D-isoascorbic acid Sodium 0.08%, sorbic acid 0.05%, 95 degree edible ethanol 0.85%, potassium cinnamate 0.15%, essence 0.26%, and the balance is water.

Embodiment 2

[0021] A purple sweet potato puree, which is composed of the following components by mass percentage: purple sweet potato 34.5%, white granulated sugar 30%, 75-degree maltose syrup 15%, sodium carboxymethyl cellulose 0.25%, modified starch 0.46%, D-isoascorbic acid Sodium 0.085%, sorbic acid 0.06%, 95-degree edible ethanol 0.85%, potassium cinnamate 0.15%, essence 0.2%, and the balance is water.

Embodiment 3

[0023] A purple sweet potato puree, which is composed of the following components by mass percentage: purple sweet potato 30%, white granulated sugar 40%, 75-degree maltose syrup 10%, sodium carboxymethyl cellulose 0.3%, modified starch 0.5%, D-isoascorbic acid Sodium 0.1%, sorbic acid 0.1%, 95 degree edible ethanol 0.9%, potassium cinnamate 0.2%, essence 0.3%, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com