A preparation method of loaded ammonium perchlorate/graphene oxide three-dimensional energetic material

An ammonium perchlorate, supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Heat conduction path and other issues, to achieve the effect of low cost, high yield, and increase the burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

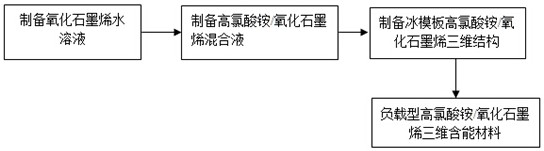

[0023] Such as figure 1 The preparation method of the shown loaded ammonium perchlorate / graphene oxide three-dimensional energetic material comprises the following steps:

[0024] The first step is to prepare a uniformly dispersed graphene oxide aqueous solution, (1) select natural graphite flakes, use the improved Hummers' method to exfoliate graphene oxide, and adjust the concentration of the exfoliated graphene oxide aqueous solution to 10 mg / mL;

[0025] (2) Perform high-intensity ultrasonic treatment, and treat the graphene oxide aqueous solution in an ultrasonic disperser for more than 90 minutes, so that the diameter of the graphene oxide sheet is 20-50 microns and the thickness is 1.5-11.3 nanometers;

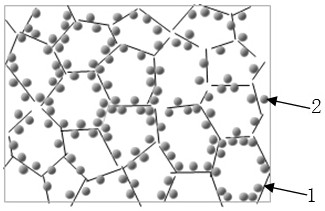

[0026] The second step is to use the ice template method to make ammonium perchlorate and graphene oxide form a three-dimensional structure. (1) Dissolve ammonium perchlorate crystal particles in graphene oxide aqueous solution. The mass ratio of ammonium perchlorate to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com