BiOCOOH/g-C3N4 composite photocatalyst and preparation method and application thereof

A g-c3n4, composite light technology, applied in catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the complex synthesis process, affect practical application, and increase cost and other problems, to achieve the effect of high catalytic activity, high degradation efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] According to a second aspect of the present invention, there is provided a BiOCOOH / g-C 3 N 4 The preparation method of composite photocatalyst comprises the following steps:

[0057] will g-C 3 N 4 , soluble bismuth salt and solvent to synthesize BiOCOOH / g-C by hydrothermal method 3 N 4 Composite photocatalyst; soluble bismuth salt and g-C 3 N 4 The molar ratio is (0.15~4.75):1.

[0058] Soluble Bismuth Salt and g-C 3 N 4 Typical but non-limiting molar ratios are, for example, 0.15:1, 0.25:1, 0.3:1, 0.5:1, 0.8:1, 1:1, 1.2:1, 1.5:1, 1.8:1, 2:1 , 2.5:1, 3:1, 4:1, or 4.75:1.

[0059] Hydrothermal synthesis refers to the synthesis by chemical reaction of substances in aqueous solution at a temperature of 100-1000°C and a pressure of 1MPa-1GPa. Under hydrothermal conditions, because the reaction is at the molecular level, the reactivity is enhanced, so hydrothermal reactions can replace some high-temperature solid-state reactions. Use hydrothermal method to synth...

Embodiment 1

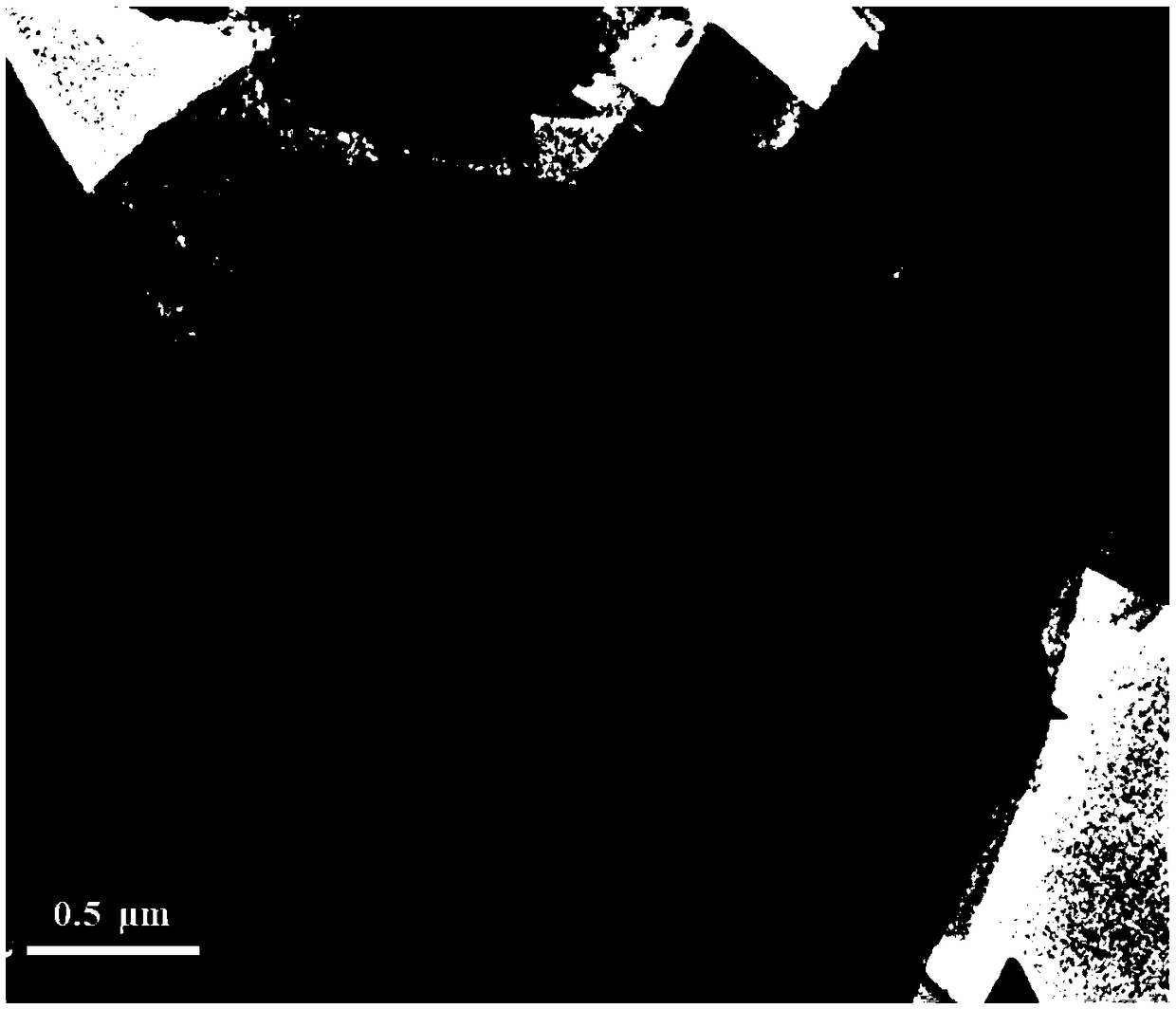

[0107] A BiOCOOH / g-C 3 N 4 Composite photocatalyst, flower-like BiOCOOH embedded in g-C 3 N 4 In the sheet structure; BiOCOOH and g-C 3 N 4 The molar ratio is 3:1;

[0108] The above BiOCOOH / g-C 3 N 4 The preferred preparation method of composite photocatalyst comprises the following steps:

[0109] (1) Add 1 mmol of bismuth nitrate pentahydrate to 5 mL of N, N-dimethylformamide, and mix well at room temperature until transparent;

[0110] (2) Add 40mL of deionized water and mix ultrasonically for 5min;

[0111] (3) Add 0.031g g-C 3 N 4 Powder, ultrasonically mixed for 5 minutes;

[0112] (4) Transfer the suspension obtained in step (3) into a 100mL stainless steel autoclave lined with polytetrafluoroethylene, and keep it warm at 130°C for 11h;

[0113] (5) The product obtained in step (4) was centrifuged, washed three times with deionized water and absolute ethanol, dried at 70°C for 10 hours, and ground to obtain BiOCOOH / g-C with a particle size of about 1200nm ...

Embodiment 2

[0115]A BiOCOOH / g-C 3 N 4 Composite photocatalyst, flower-like BiOCOOH embedded in g-C 3 N 4 In the sheet structure; BiOCOOH and g-C 3 N 4 The molar ratio is 0.25:1;

[0116] The above BiOCOOH / g-C 3 N 4 The preferred preparation method of composite photocatalyst comprises the following steps:

[0117] (1) Add 1 mmol of bismuth nitrate pentahydrate to 5 mL of N, N-dimethylformamide, and mix well at room temperature until transparent;

[0118] (2) Add 40mL of deionized water and mix ultrasonically for 5min;

[0119] (3) Add 0.368g g-C 3 N 4 Powder, ultrasonically mixed for 5 minutes;

[0120] (4) Transfer the suspension obtained in step (3) into a 100mL stainless steel autoclave lined with polytetrafluoroethylene, and keep it warm at 130°C for 11h;

[0121] (5) Centrifuge the product obtained in step (4), wash with deionized water and absolute ethanol for 5 times, dry at 50°C for 14 hours, and grind to obtain BiOCOOH / g-C with a particle size of about 300nm 3 N 4 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com