Manufacturing process of machine tool bed with outer protective cover

A technology for an outer protective cover and a manufacturing process, which is used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc. Internal stress, the effect of avoiding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

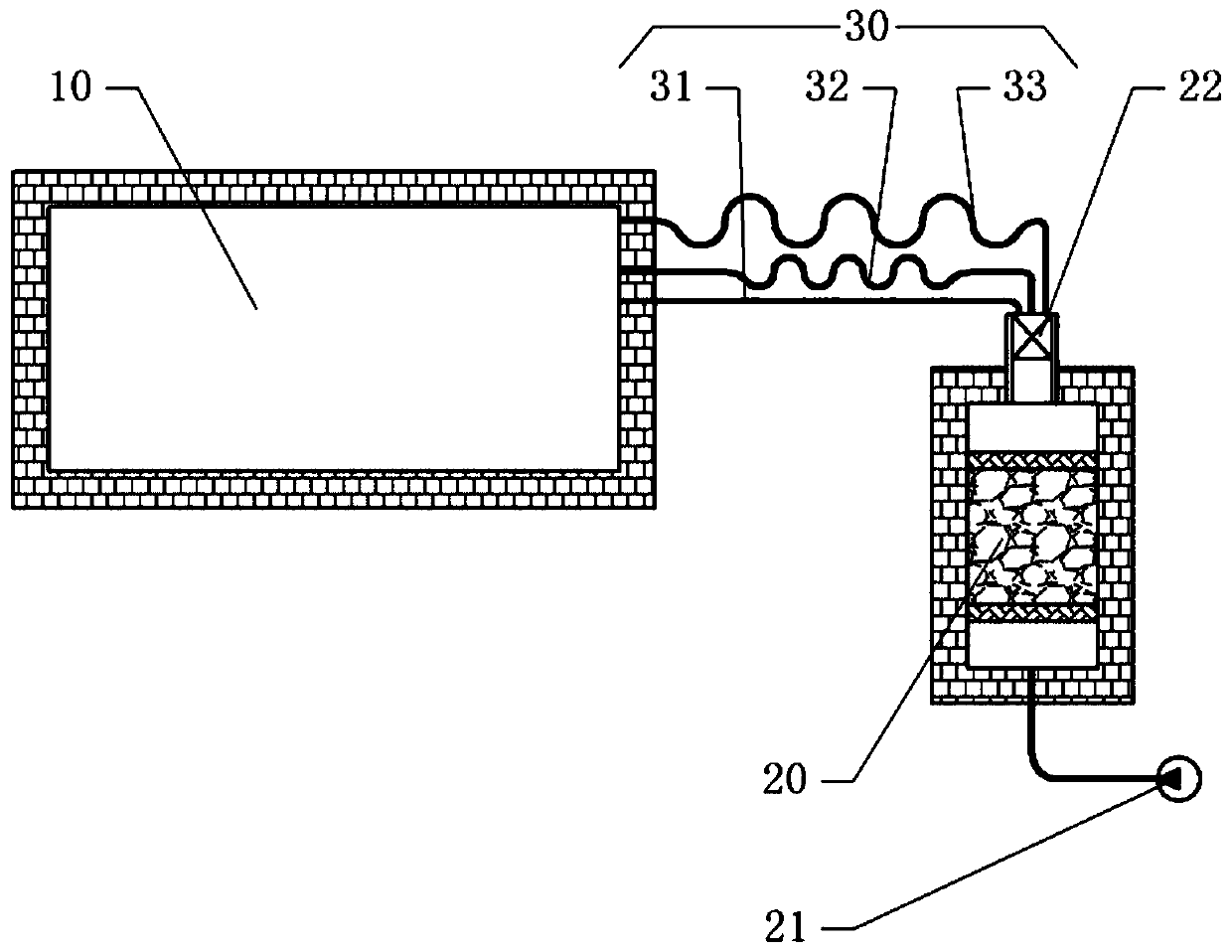

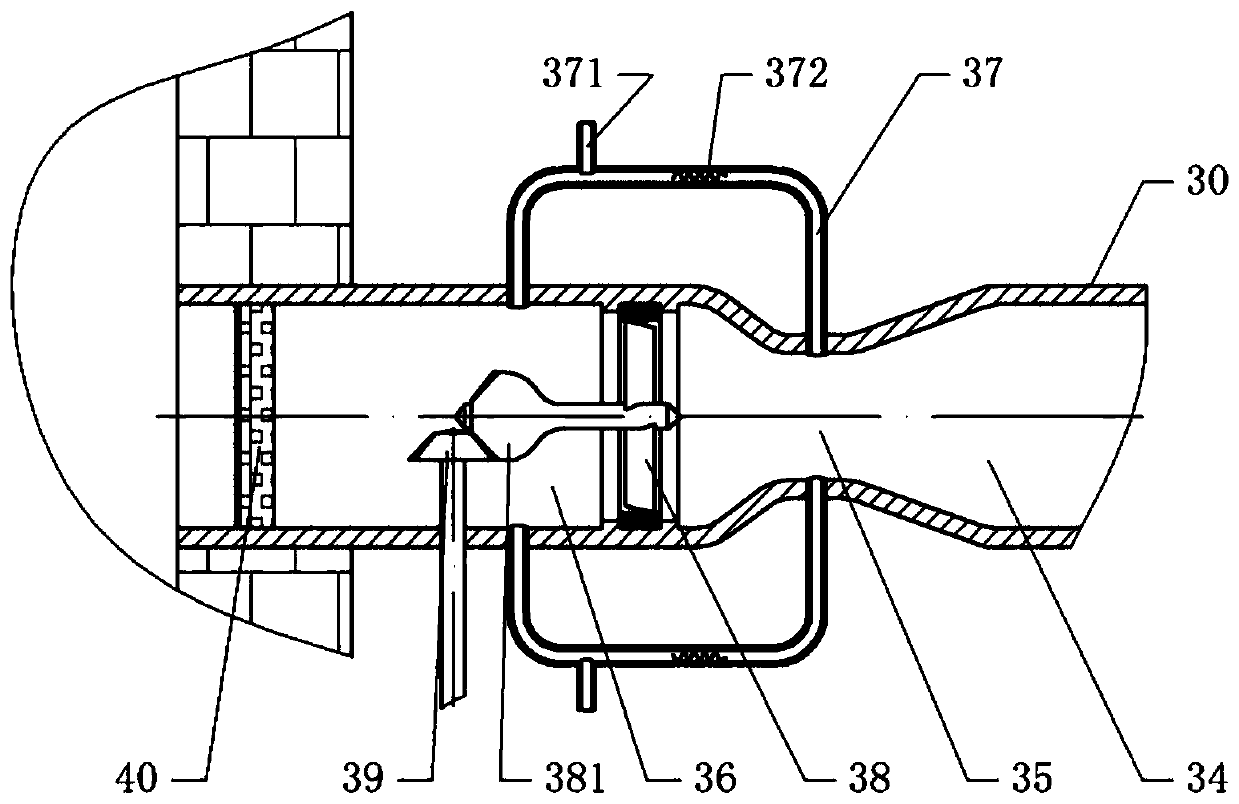

[0024] The reference numerals in the drawings of the description include: heating furnace 10, charcoal layer 20, air pump 21, reversing valve 22, exhaust pipe 30, first pipe 31, second pipe 32, third pipe 33, inlet section 34, Throat 35, diffusion section 36, suction pipe 37, air inlet 371, heating wire 372, impeller 38, first bevel gear 381, second bevel gear 39, drying bag 40.

[0025] The embodiment is basically as figure 1 , figure 2 Shown:

[0026] The manufacturing process of the outer protective cover machine bed of the present embodiment, the product outer protective cover machine bed includes a steel skeleton, and the steel skeleton includes a left box body, a right box body, and a connecting plate connecting the left box body and the right box body. The guide rail supporting plate at the upper end of the left box body and the right box body and the bed base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com