Ultrasonic-assisted abrasive jet deburring machining device

A technology of abrasive jet and processing equipment, which is applied in the direction of used abrasive processing equipment, abrasives, metal processing equipment, etc., can solve the problems of uneven quality, low efficiency, environmental pollution, etc., and achieve high processing efficiency, low cost, and enhanced The effect of degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Solutions similar to this case made by other persons in the art are within the protection scope of the present invention.

[0025] Such as Figure 1-4 shown.

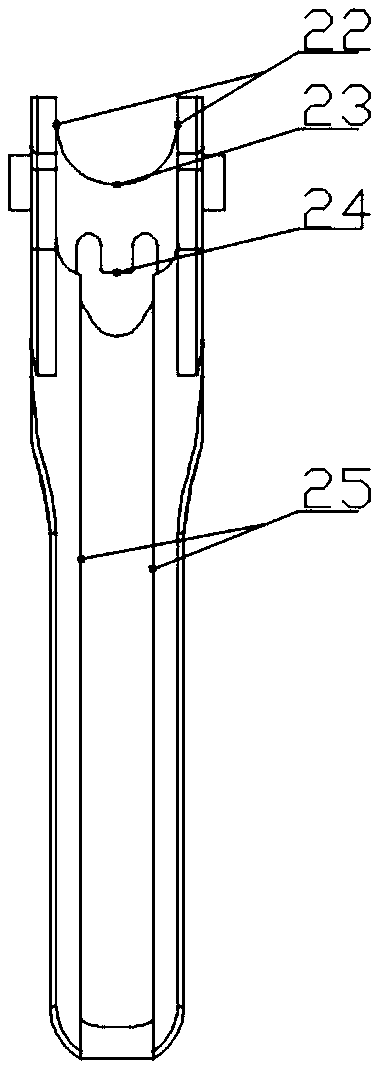

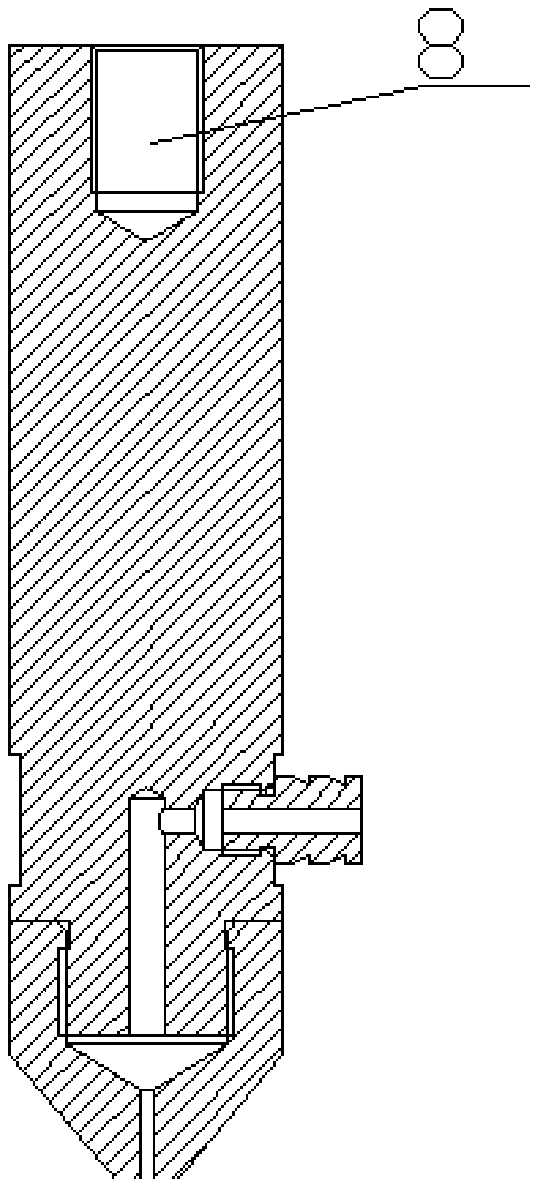

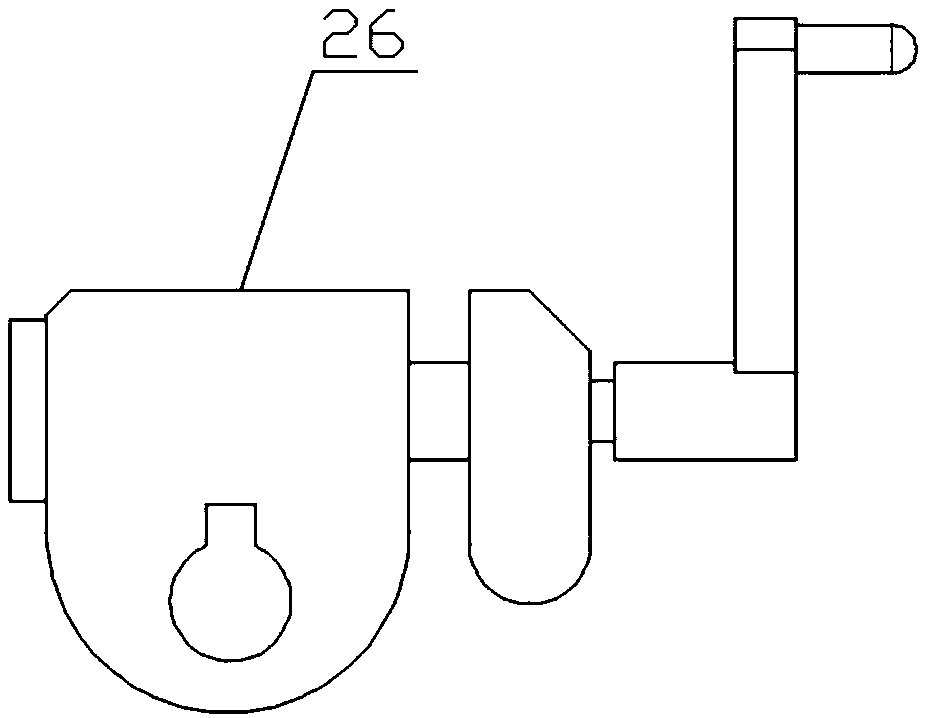

[0026] one for figure 1 The ultrasonic-assisted abrasive jet deburring processing device for removing burrs in the inner holes of the parts shown, its overall structure is as follows Figure 4 As shown, it includes: lifting mechanism 1, part fixture 2 (such as image 3 ), abrasive liquid mixing box 3, high-precision two-axis workbench 4, stirring mechanism 5, transducer 6, horn 7, vibration rod nozzle 8 (such as figure 2 ), temperature sensor 9, ultrasonic power supply 10, microcontroller 11, hose 12, clamp 13, stainless steel jet 14, turbine flow sensor 15, electric control valve 16, notebook computer 17, pressure gauge 18, pulsation damper 19, safety Valve 20, hydraulic diaphragm p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com