Process for producing refined sulfuric acid by sulphuric acid plant

A sulfuric acid and process technology, applied in the fields of sulfur compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of high raw material quality and flue gas pretreatment requirements, reduce flue gas pretreatment load, improve product quality, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

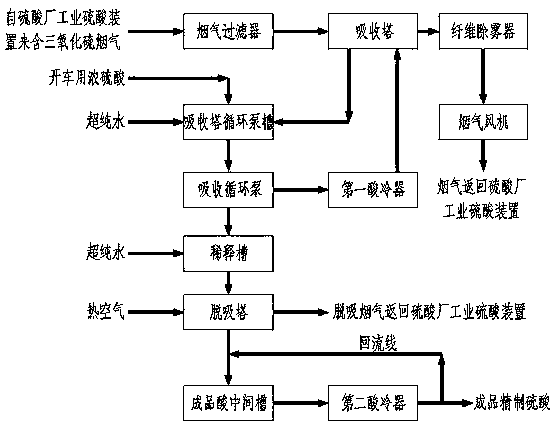

Image

Examples

Embodiment 1

[0023] A process for producing refined sulfuric acid in a sulfuric acid plant. The process flow is as follows: 1) Extract the flue gas from the primary transformation of the copper smelting acid plant, containing about 15% (V) of sulfur trioxide, and remove the acid mist through the flue gas filter After being mixed with smoke and dust, it enters the absorption tower, where it is sprayed with 98.3% sulfuric acid at about 50°C. After the flue gas is demistered by the fiber demister, it is sent back to the copper smelting acid plant by the flue gas fan. The concentrated sulfuric acid in the absorption tower enters the circulation pump tank of the absorption tower, and ultrapure water is added to adjust the acid concentration to 98.3%, and the acid temperature is about 90°C. The circulation pump tank of the absorption tower is sent to the acid cooler through the absorption tower circulation pump to cool down to 50°C and returned to the absorption tower for spraying. The sulfuric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com