Low-temperature fast-fired low-clay glazed green brick and method for preparing same

A glazed tile and green body technology, which is applied in the field of low-temperature fast-firing low-clay glazed tile green body and its preparation field, can solve the problems of high biscuit firing temperature, large loss, and large limitation of raw materials, and achieves low firing temperature and waste material. Reduced, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

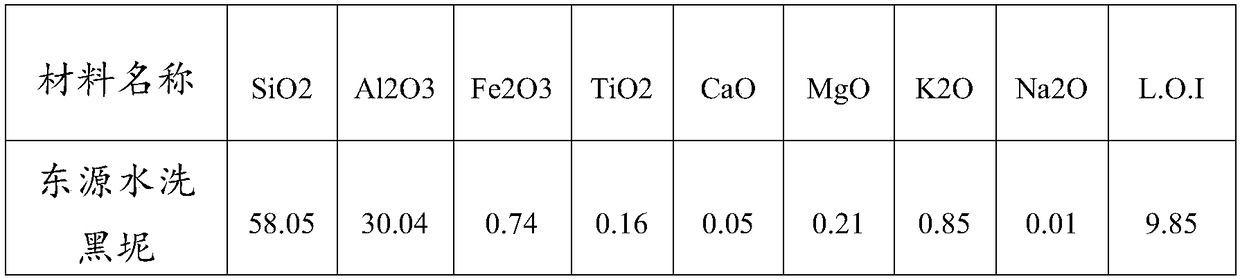

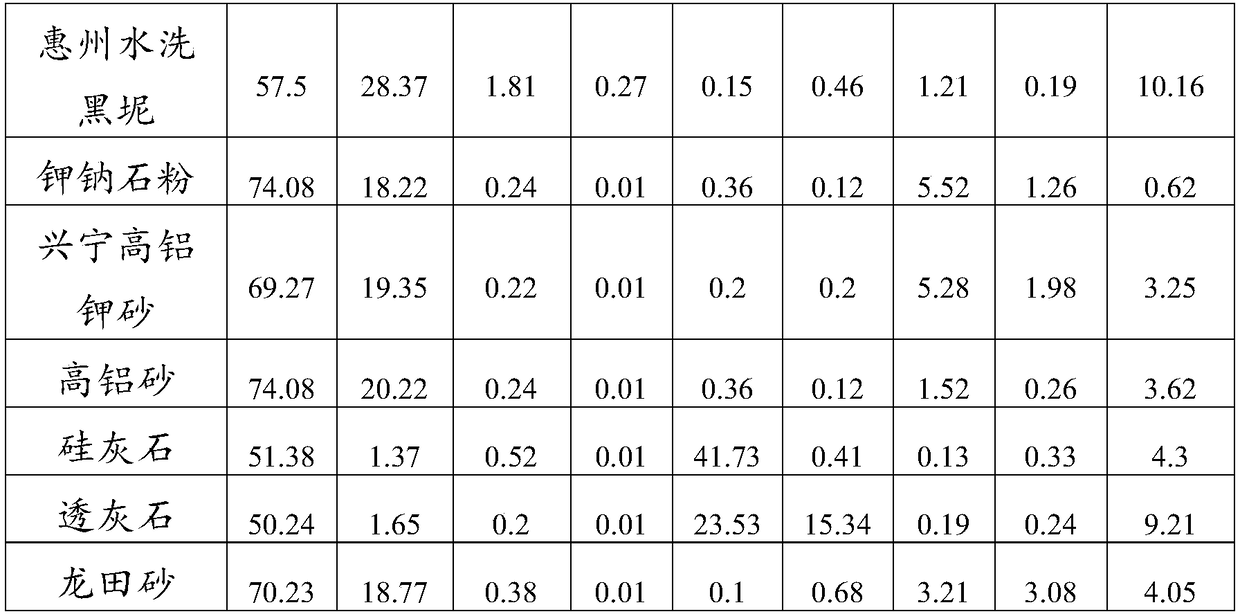

[0037] Embodiment 1: Weigh the raw materials according to the following mass percentages: 10% of Dongyuan washed black clay, 13% of potassium sodium stone powder, 12% of Xingning high-alumina potassium sand, 28% of high-alumina sand, and 5% of wollastonite , Lime 10%, Longtian sand 22%, mix them in a rotary mixer; then add a certain amount of water, and at the same time add a mass fraction of 10% of the total weight of glazed brick body raw materials to be 10wt% polyvinyl alcohol solution , sent to a ball mill for ball milling, and then sieved to remove iron; the glazed brick body raw material after iron removal was spray-dried to obtain brick body powder; the brick body powder was pressed and formed, and then dried at 140°C After 90 minutes, the adobe was prepared, and then bisque fired at 1050°C for 40 minutes to obtain the first-fired biscuit for subsequent glazing treatment. After measurement, the dry strength of the glazed brick body is 1.41MPa, and the flexural strength ...

Embodiment 2

[0038]Embodiment 2: Weigh the raw materials according to the following mass percentages: 14% of Dongyuan washed black stone powder, 18% of potassium sodium stone powder, 17% of Xingning high-alumina potassium sand, 23% of high-alumina sand, and 4% of wollastonite , Lime 7%, Longtian sand 17%, it is mixed in the rotary mixer; Then add a certain amount of water, and add 8% of the total weight of the raw material of the glazed brick body at the same time, the mass fraction is 8wt% polyvinyl alcohol The solution is sent to a ball mill for ball milling, and then sieved to remove iron; the glazed brick body raw material after iron removal is spray-dried to obtain brick body powder; the brick body powder is pressed and formed, and then Dry for 100 minutes to make adobe, and then biscuit firing at 1080°C for 50 minutes to obtain the first-fired biscuit for subsequent glazing treatment. After measurement, the dry strength of the glazed tile body is 1.45MPa, and the flexural strength of...

Embodiment 3

[0039] Embodiment 3: Weigh the raw materials according to the following mass percentages: 15% of Dongyuan washed black clay, 23% of potassium sodium stone powder, 22% of Xingning high-alumina potassium sand, 20% of high-alumina sand, and 2% of wollastonite , Lime 5%, Longtian sand 13%, mix it in a rotary mixer; then add a certain amount of water, and add 5% of the total weight of the raw materials of the glazed brick body at the same time. The mass fraction is 5wt% polyvinyl alcohol The solution is sent to a ball mill for ball milling, and then sieved to remove iron; the glazed brick body raw material after iron removal is spray-dried to obtain brick body powder; the brick body powder is pressed and formed, and then Dry for 120 minutes to make adobe, and then biscuit firing at 1100°C for 60 minutes to obtain the first-fired biscuit for subsequent glazing treatment. After measurement, the dry strength of the glazed tile body is 1.48MPa, and the flexural strength of the green bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com