Novel lithium ion conduction oxide solid electrolyte and method for preparing same

A solid electrolyte, lithium ion technology, applied in the field of new lithium ion conductive oxide solid electrolyte and its preparation, can solve the problems of increased interface resistance and poor electrochemical stability of solid-state batteries, achieve excellent chemical stability, and promote uniform mixing. , the effect of easy sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] like Figure 4 Shown, the present invention provides a kind of preparation method of novel oxide solid electrolyte, and it comprises the steps:

[0031] S1 wet ball milling mixed raw materials:

[0032] Weigh and analyze the pure chemical raw material lithium source (Li) according to the designed stoichiometric ratio 2 CO 3 , LiOH), Ta 2 o 5 , ZrO 2 , SiO 2 , and placed in a 100ml zirconia ball mill jar (the material of the ball mill is ZrO 2), add 30ml of ball milling liquid (ethanol, isopropanol or water), and use a planetary ball mill to mill for 24h under the condition of 50 rpm to realize the mixing of raw material powder, wherein the solid electrolyte is Li 1+x Ta 1-x Zr x SiO 5 , the content of doping components is 05 Formation;

[0033] S2 Calcination to prepare powder:

[0034] After the mixed slurry is dried, it is calcined at 850°C to 950°C for 12 to 24 hours to realize the decomposition of the lithium source in the raw material and the preliminar...

Embodiment 1

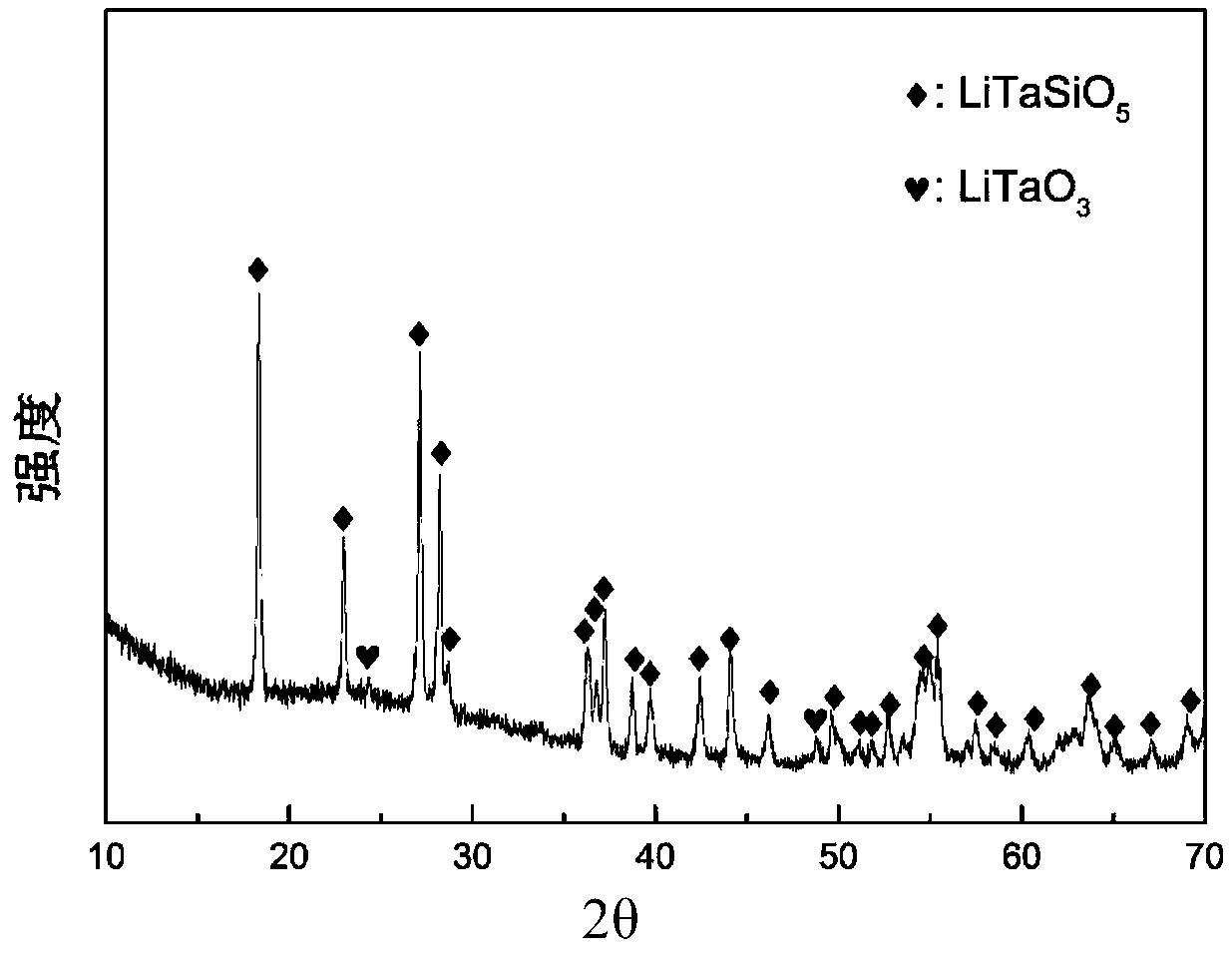

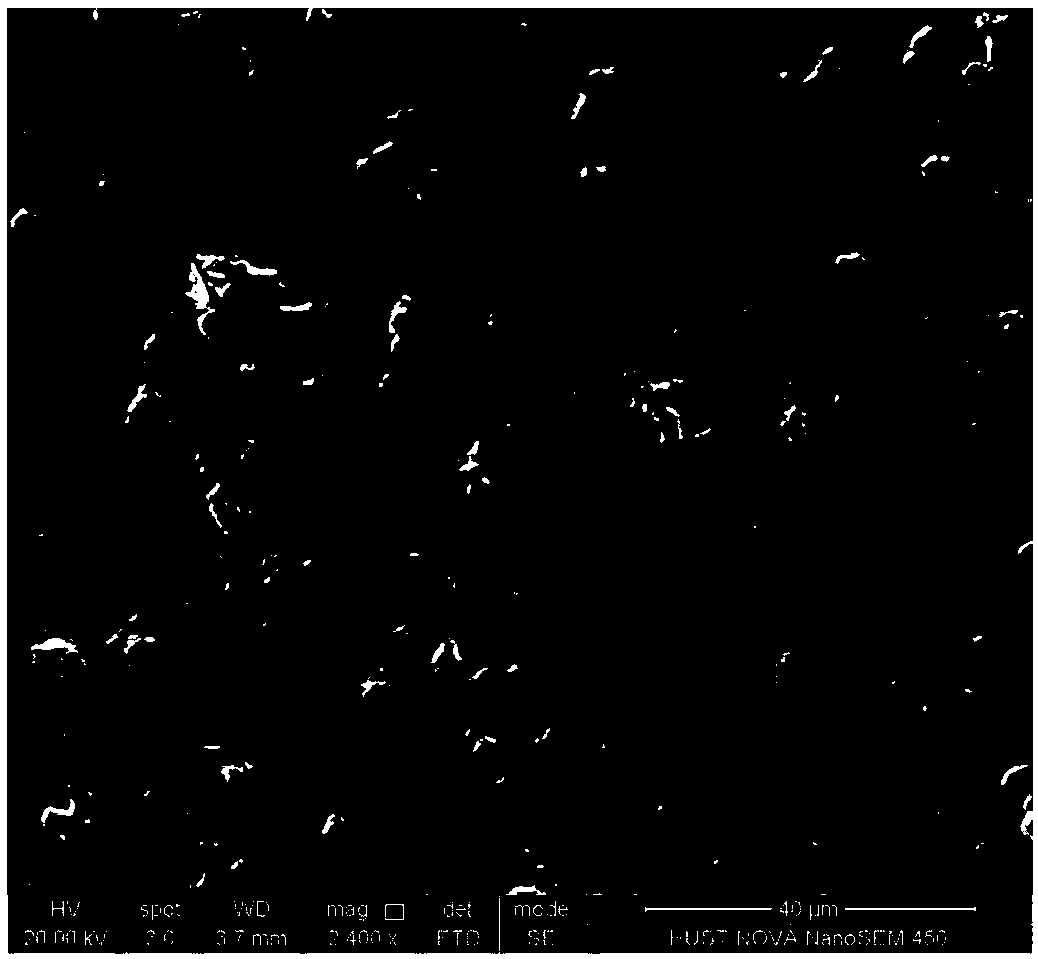

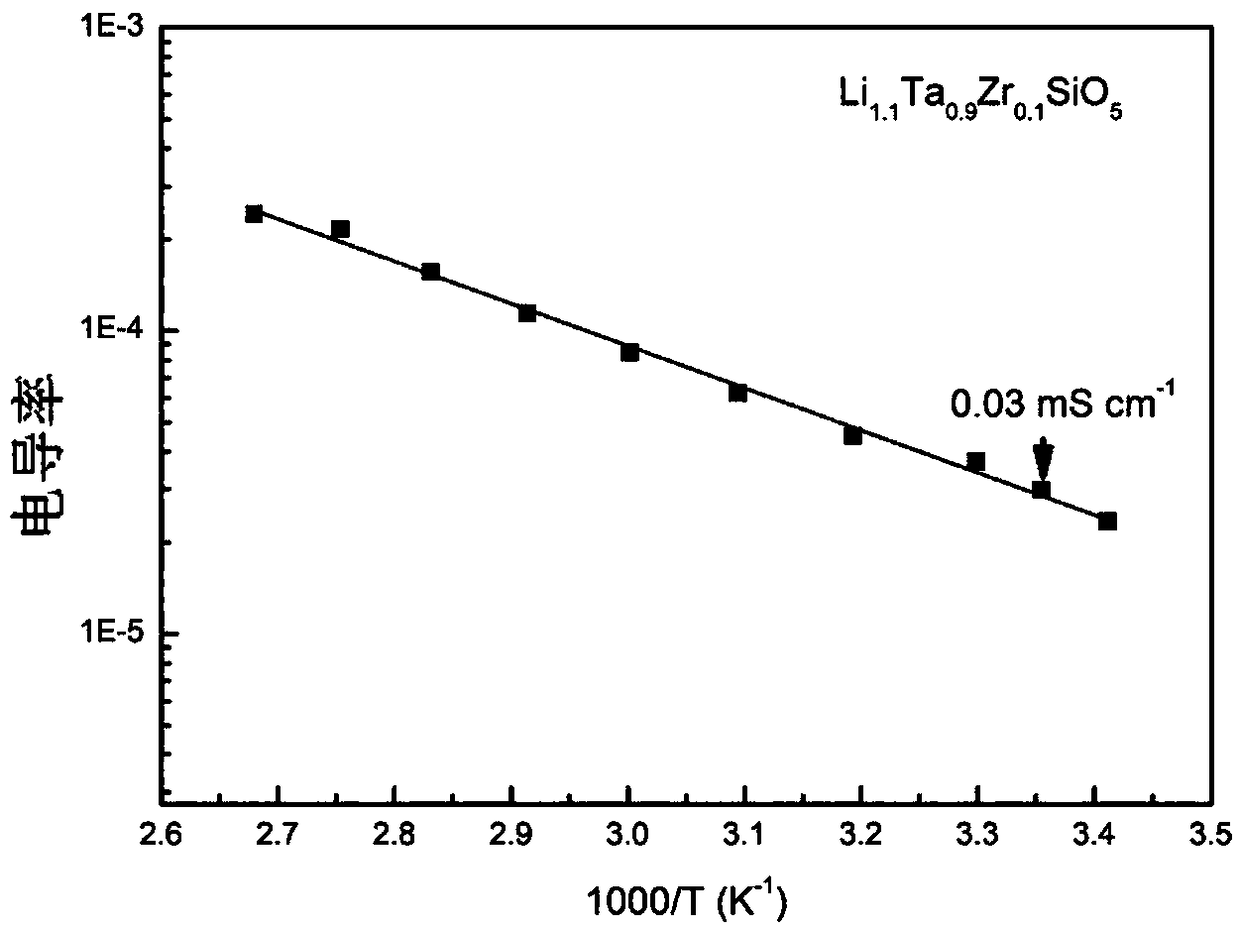

[0040] Li 1.1 Ta 0.9 Zr 0.1 SiO 5 Preparation of solid electrolyte, wherein lithium content is excessive 1%, tantalum is missing 1%, and silicon content is excessive 5%, the specific steps are as follows:

[0041] Weigh the raw material powder according to the designed stoichiometric ratio, that is, according to the chemical formula Li 1.1 Ta 0.9 Zr 0.1 SiO 5 Calculate the amount of each raw material, then adjust the amount of the raw material to make it lower or higher than the calculated value according to the excess or missing requirements, and finally weigh each raw material according to the adjusted value, for example, according to the chemical formula Li 1.1 Ta 0.9 Zr 0.1 SiO 5 Calculate Li 2 CO 3 、 Ta 2 o 5 , ZrO 2 and SiO 2 Respective amount, Li is adjusted according to 0% excess lithium content, 0% tantalum deficiency, and 5% excess silicon content 2 CO 3 、 Ta 2 o 5 and SiO 2 The amount of lithium content in excess of 0%, then Li 2 CO 3 The amoun...

Embodiment 2

[0046] Li 1.05 Ta 0.95 Zr 0.05 SiO 5 The preparation of the solid electrolyte, wherein the excess lithium content is 0%, the tantalum is missing 2%, and the silicon content is excessive 3%, the specific steps are as follows:

[0047] Weigh the raw material powder according to the designed stoichiometric ratio, that is, according to the chemical formula Li 1.05 Ta 0.95 Zr 0.05 SiO 5 Calculate the amount of each raw material, and then adjust the amount of raw materials according to the excess or lack of requirements to make it lower or higher than the calculated value, and finally weigh each raw material according to the adjusted value, that is, weigh Li according to the respective amount 2 CO 3 、 Ta 2 o 5 , ZrO 2 and SiO 2 , and then placed in a 100ml zirconia ball mill jar, added 30ml of ethanol, and ball milled for 24h under the condition of 50 rpm to obtain a mixed slurry of raw materials;

[0048] The slurry mixed with raw materials was dried at 100°C, transferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electronic conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com