Lithium-ion battery gel electrolyte and preparation method thereof

A gel electrolyte and lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor mechanical properties, discounted battery performance, and difficulty in dispersing, so as to increase the conductivity of lithium ions and increase heat dissipation. Stability, beneficial effect of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of liquid-filled batteries: graphite and lithium cobaltate are used as active materials for anode and cathode, respectively, conductive agents and adhesives are added, and the anode and cathode to be wound are obtained through stirring, coating, cold pressing, slitting, welding and other processes. The pole piece is then wound together with the separator to obtain the bare cell, and the aluminum-plastic film is used to seal the top and side of the packaging bag, and then baked in a Baking furnace until the water content is lower than 200ppm;

[0038] Liquid injection and cell molding: inject the prepared electrolyte into the baked cell, let it stand until the electrolyte fully infiltrates the entire diaphragm, and then perform heating polymerization, shaping, degassing and other processes to finally obtain the formed cell core.

Embodiment 1

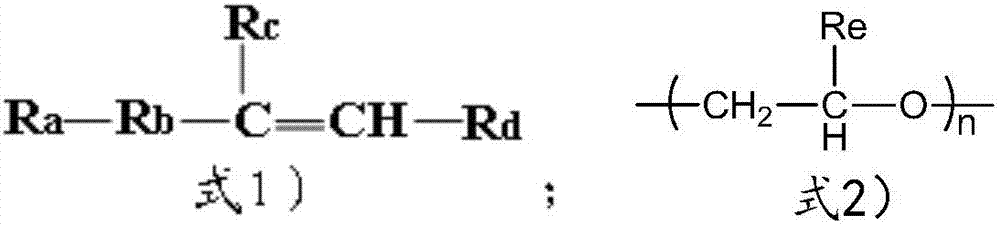

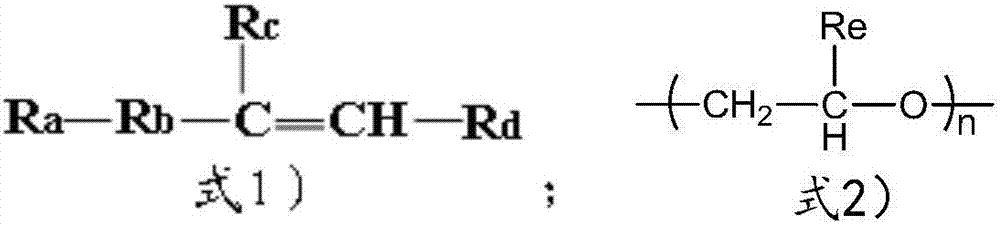

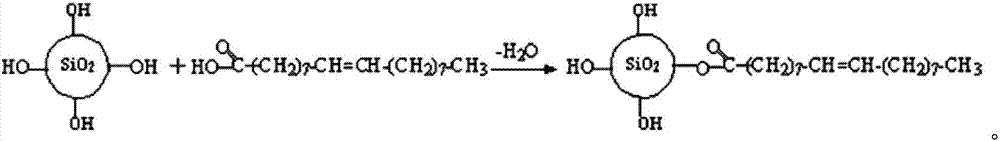

[0040] Organic compound-nanoparticle composite SiO 2 -OA1 (OA1 here is for SiO 2 A naming method of -O-A, where A refers to the organic compound monomer, SiO 2and the organic compound monomer are connected by -O-bond, and the following OA2 has the same meaning) synthesis:

[0041] 1g of nano-SiO with an average particle size of 20nm 2 Disperse in 200ml n-hexane solution to obtain a suspension; at room temperature, add 0.5g (COOH-CH 2 -CH 2 -O-CH=CH 2 ) Propionic acid vinyl ether, heated up to 60 ℃ and reacted for 4h; the obtained liquid was filtered, and water and organic solvent were distilled off under reduced pressure to obtain a clear and transparent organic compound-nanoparticle composite agent SiO 2 -OA1, about 90% yield.

Embodiment 2

[0043] Organic compound-nanoparticle composite SiO 2 Synthesis of -OA2:

[0044] 1g of nano-SiO with an average particle size of 20nm 2 Disperse into 200ml of n-hexane solution to obtain a suspension; add 15g of propionic acid vinyl ether to the suspension at room temperature, raise the temperature to 60°C and react for 4h; filter the obtained liquid, and distill under reduced pressure to remove water and organic Solvent, that is, to obtain a clear and transparent organic compound-nanoparticle composite agent SiO 2 -OA2 in about 91% yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com