Method for preparing nano-porous material based on annular micelle multi-stage assembling

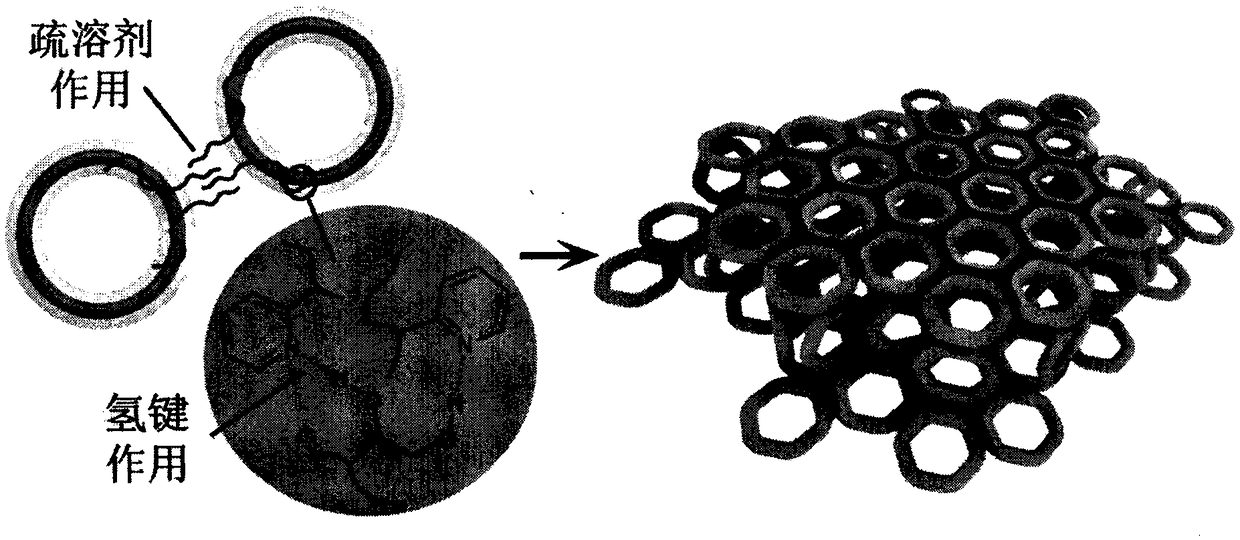

A nanoporous and micelle technology, which is applied in the field of preparation of nanoporous materials, can solve the problem that the induced assembly method is difficult to control the uniformity of the pore structure, and achieve the effect of low assembly efficiency, uniform size and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] (1) Preparation of cyclic micelles

[0046]Tetrahydrofuran was purified by sodium distillation under nitrogen atmosphere; isoprene, 2-vinylpyridine, and 1,1-stilbene were stirred overnight with calcium hydride, then purified by distillation, and then added a small amount of trioctyl aluminum, purified by distillation; lithium chloride , p-tert-butylphenol is treated at a high temperature of 120°C.

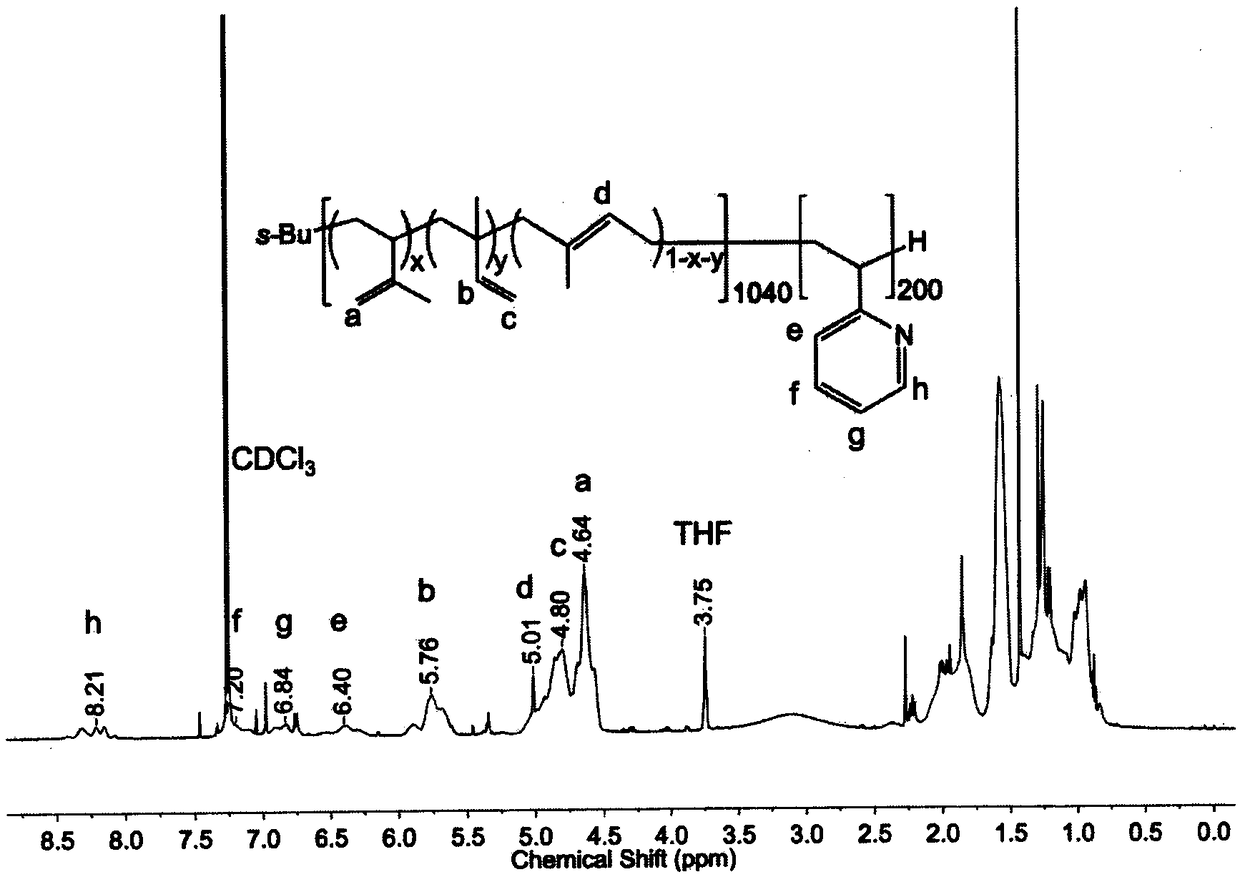

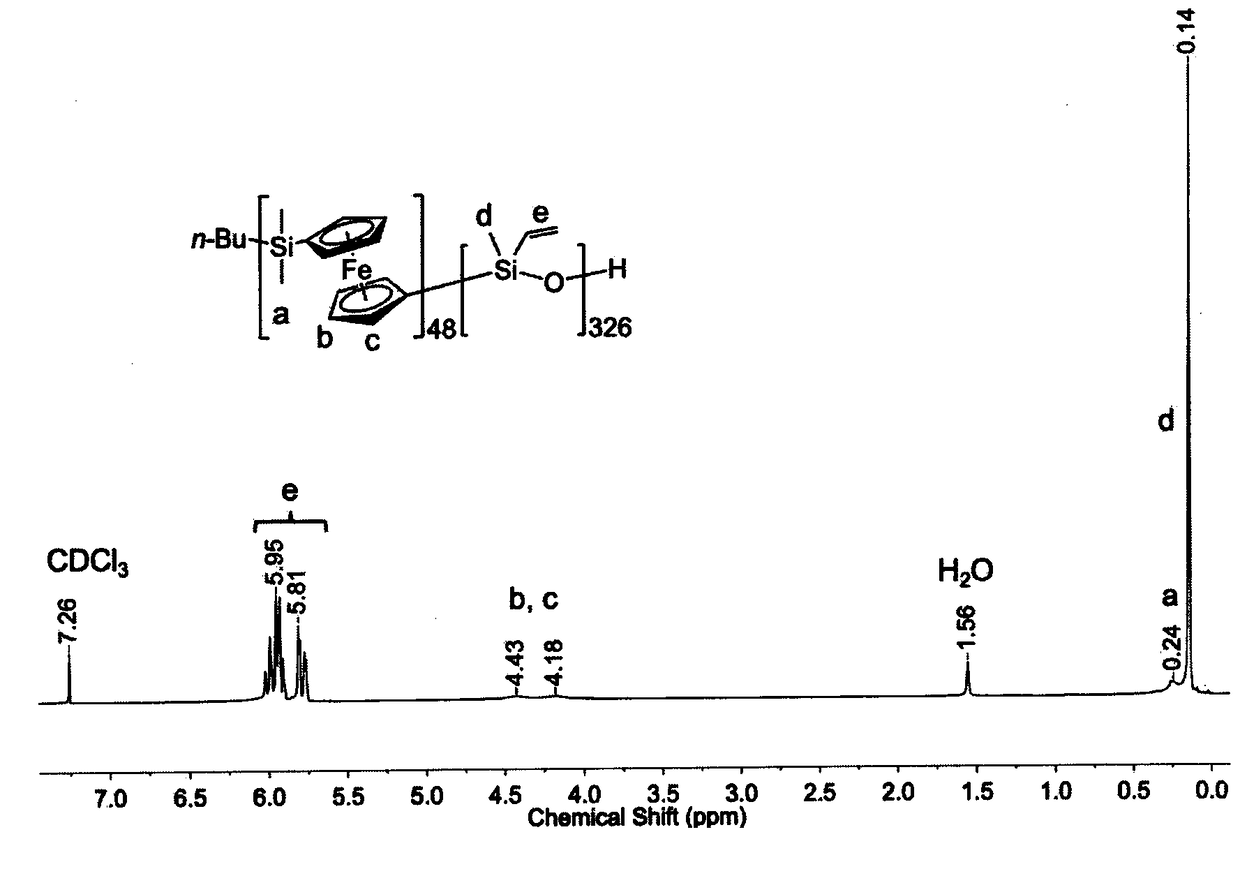

[0047] Preparation of polyisoprene-b-poly(2-vinylpyridine) block copolymer by anionic polymerization: Dissolve isoprene (1 mL, 10.0 mmol) in tetrahydrofuran in an argon atmosphere glove box (20 mL), 1.3 M sec-butyllithium (7.4 μL, 9.6 μmol) was added under stirring conditions to initiate monomer polymerization, and the reaction was stirred at -30° C. for 4 h. Subsequently, 2 mL of the solution was taken out, and a small amount of p-tert-butylphenol was added to terminate the reaction, which was used for subsequent H-NMR and gel permeation chromatography analyses. The remai...

Embodiment 2

[0060] A method for preparing nanoporous materials based on multi-stage assembly of annular micelles, the specific steps are:

[0061] (1) Preparation of cyclic micelles

[0062] Tetrahydrofuran was purified by sodium distillation under nitrogen atmosphere; isoprene, 2-vinylpyridine, and 1,1-stilbene were stirred overnight with calcium hydride, then purified by distillation, and then added a small amount of trioctyl aluminum, purified by distillation; lithium chloride , p-tert-butylphenol is treated at a high temperature of 120°C.

[0063] Preparation of polyisoprene-b-poly(2-vinylpyridine) block copolymer by anionic polymerization: Dissolve isoprene (1 mL, 10.0 mmol) in tetrahydrofuran in an argon atmosphere glove box (20 mL), 1.3 M sec-butyllithium (9.2 μL, 12 μmol) was added under stirring conditions to initiate monomer polymerization, and the reaction was stirred at -30° C. for 4 h. Subsequently, 2 mL of the solution was taken out, and a small amount of p-tert-butylpheno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com