Pretreatment method and pretreatment device before low temperature coal tar hydrogenation

A low-temperature coal tar pretreatment technology, applied in the direction of dehydration/emulsification by chemical methods, only multi-stage serial refining process treatment, refining by dialysis, etc., can solve the problem of high water content in coal tar and difficult separation of oil and water , Coal tar separation and other problems, to achieve the effect of speeding up work efficiency, increasing utilization rate, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

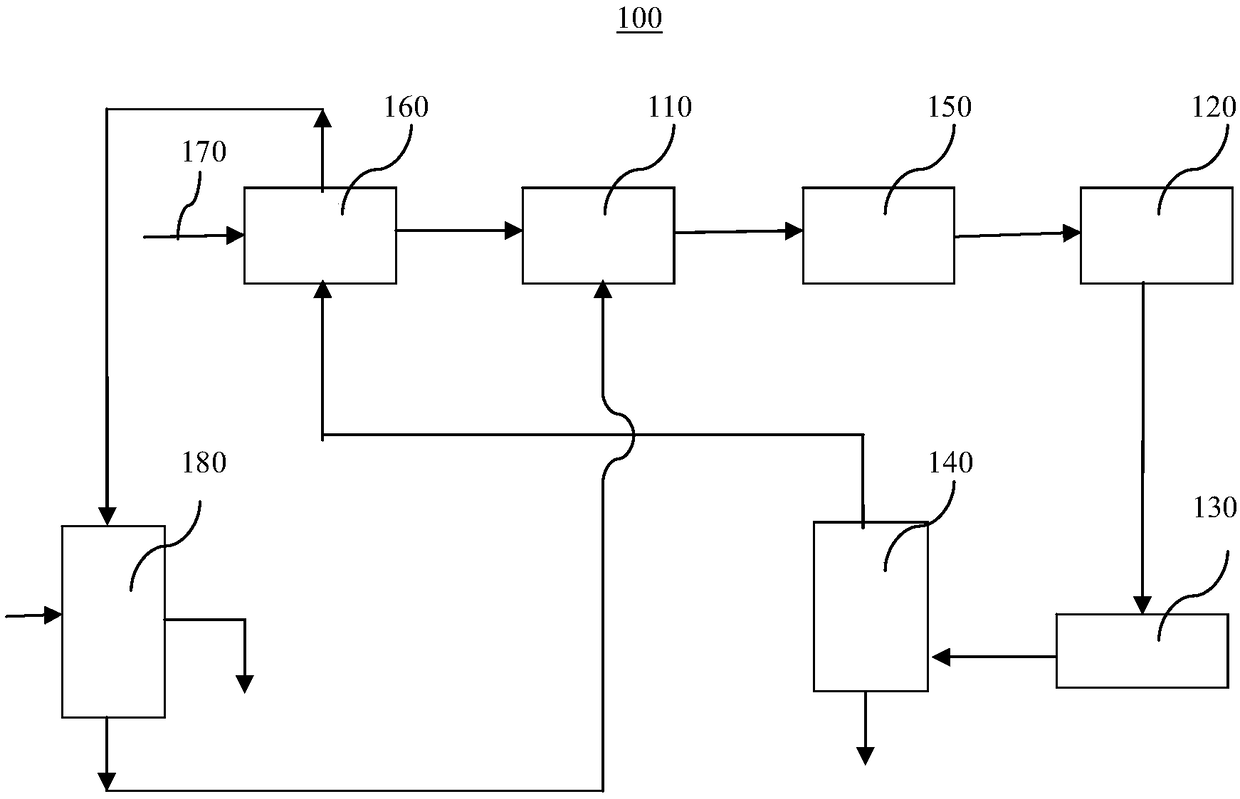

[0044] This embodiment provides a low-temperature coal tar pretreatment device 100 before hydrogenation, which includes a mixer 110, a desalination device 120, a tube furnace 130, and a flash tower 140. Among them, the mixer 110, the desalination device 120, the tube furnace 130 and the flash tower 140 are connected in series in sequence.

[0045] The mixer 110 is a place for mixing low-temperature coal tar, light oil, demulsifier, and desalinated water. The discharge end of the mixer 110 is communicated with the feed end of the filter 150. After the low-temperature coal tar, light oil, demulsifier and desalinated water are fully mixed in the mixer 110, the resulting mixed components are sent to the filter 150 Medium filtration to remove mechanical impurities, coal powder, asphalt, colloids, etc.

[0046] Further, the pretreatment equipment 100 before the low-temperature coal tar hydrogenation, also includes a heat exchanger 160, a condenser 180.

[0047] The gas phase of the flash...

Embodiment 2

[0050] This embodiment provides a pretreatment method before low-temperature coal tar hydrogenation, which adopts the pretreatment equipment 100 provided in Embodiment 1, and the specific steps include:

[0051] S1. Add low-temperature coal tar and No. 120 solvent oil, which accounts for 20% of its mass, into the mixer 110 and mix thoroughly to obtain a mixed oil with a density of 0.976 kg / L.

[0052] S2. Add demulsifier and desalinated water to mixer 110, and stir to obtain mixed components. Wherein, the mass ratio of the mixed oil, the desalinated water and the demulsifier is 100:9:0.04.

[0053] S3. The above-mentioned mixed components are heated to 120°C and transported to the filter 150 to filter out mechanical impurities, coal powder, asphalt, colloids and other substances.

[0054] S4. Keep the filtered mixed components at 120° C. and transport them to the desalination equipment 120 for desalination. After desalination, the moisture content is determined to be 0.35 wt%.

[0055]...

Embodiment 3

[0060] This embodiment provides a pretreatment method before low-temperature coal tar hydrogenation, and the specific steps include:

[0061] S1. Mix low-temperature coal tar with n-heptane accounting for 15% of its mass to obtain a mixed oil with a density of 0.970 kg / L.

[0062] S2. Mix the above mixed oil with demulsifier and desalinated water to obtain mixed components. Among them, the mass ratio of mixed oil, desalinated water and demulsifier is 100:7:0.036.

[0063] S3. Heat the above-mentioned mixed components to 140°C, filter and filter out mechanical impurities, coal powder, asphalt, colloids and other substances.

[0064] S4. Keep the filtered mixed components at 140°C for desalination, and the moisture content is determined to be 0.43 wt% after desalination.

[0065] S5. Heating the oil phase component obtained after desalination to 180° C., and then flashing to separate the gas phase component and the liquid phase component, and the gas phase component is condensed and reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com