Compact large diesel engine tail gas treatment device and method

A technology of exhaust gas treatment and diesel engine, which is applied in exhaust treatment, exhaust device, muffler device, etc. It can solve the problems of easy formation of stones, long series length, limited layout space, etc., and achieve space reduction, compact structure, and length reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0042] In order to solve the problem of tail gas reaction treatment of 400kW-560kW heavy-duty engines, the invention provides a tail gas treatment reaction device that can satisfy the overall compact layout of the reactor.

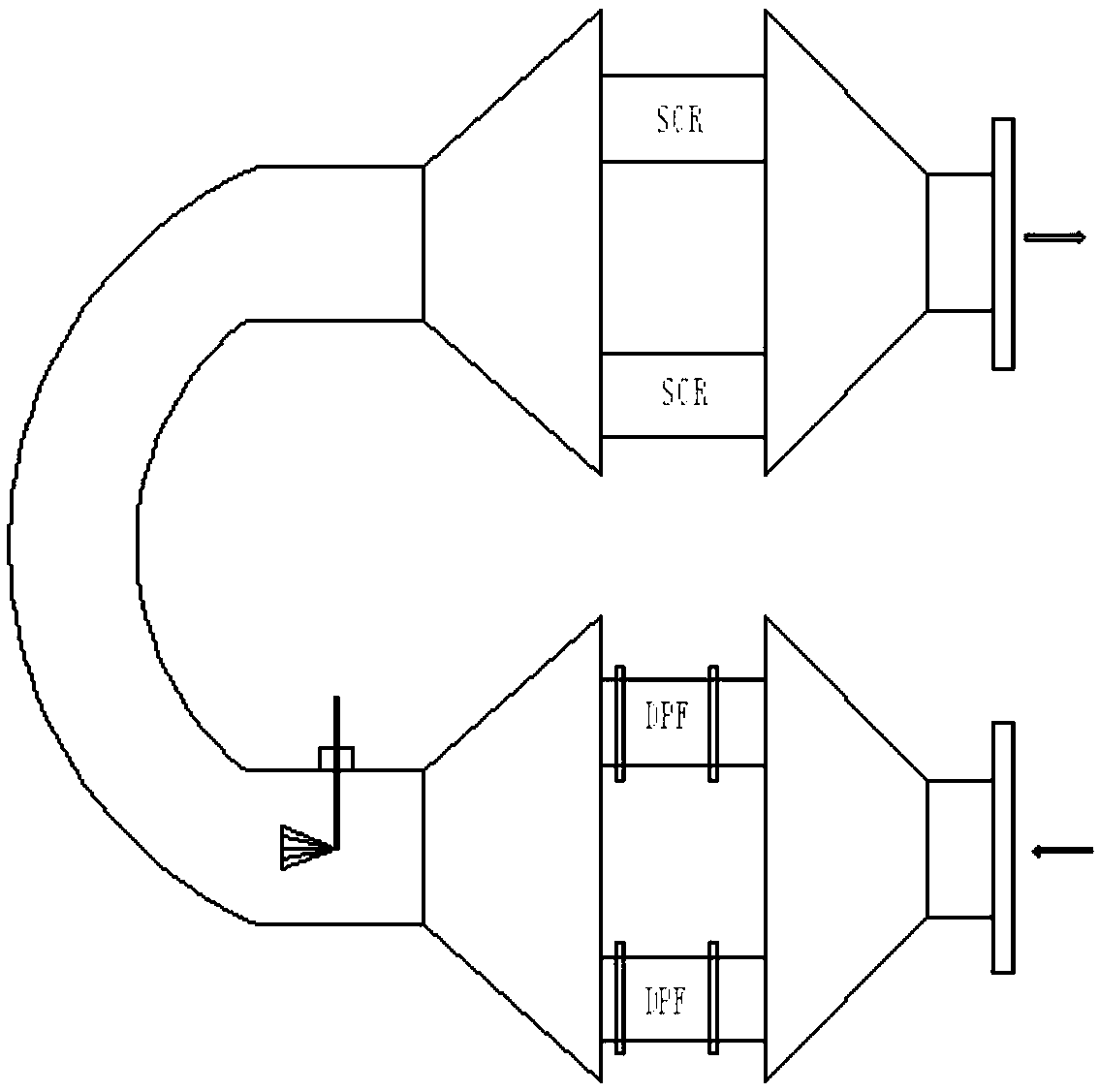

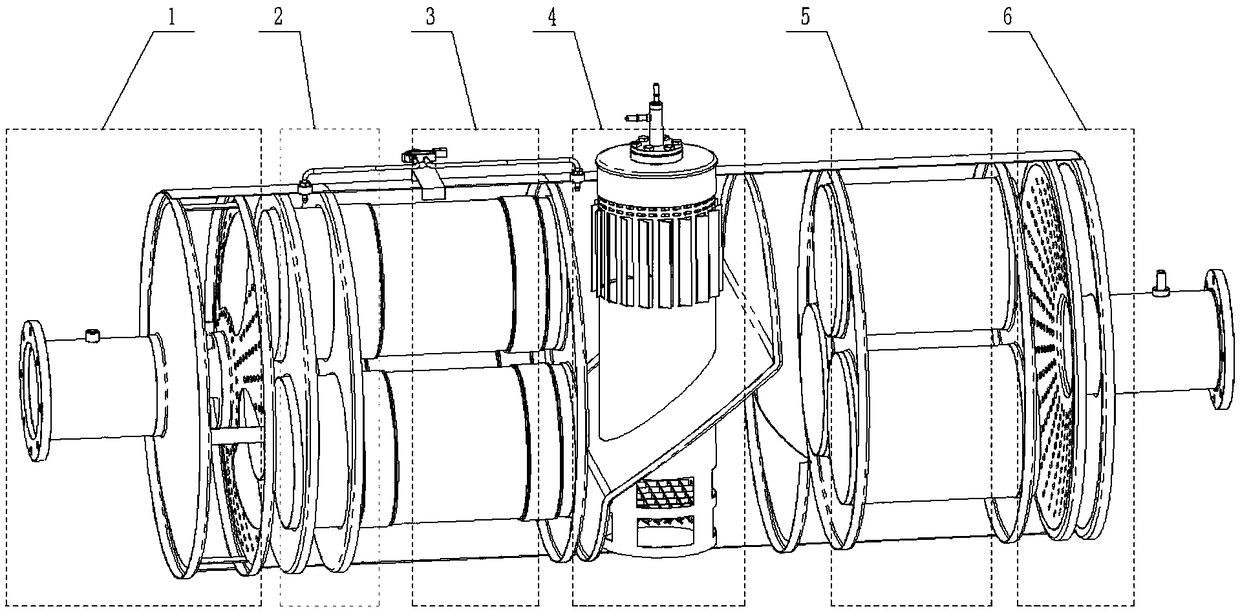

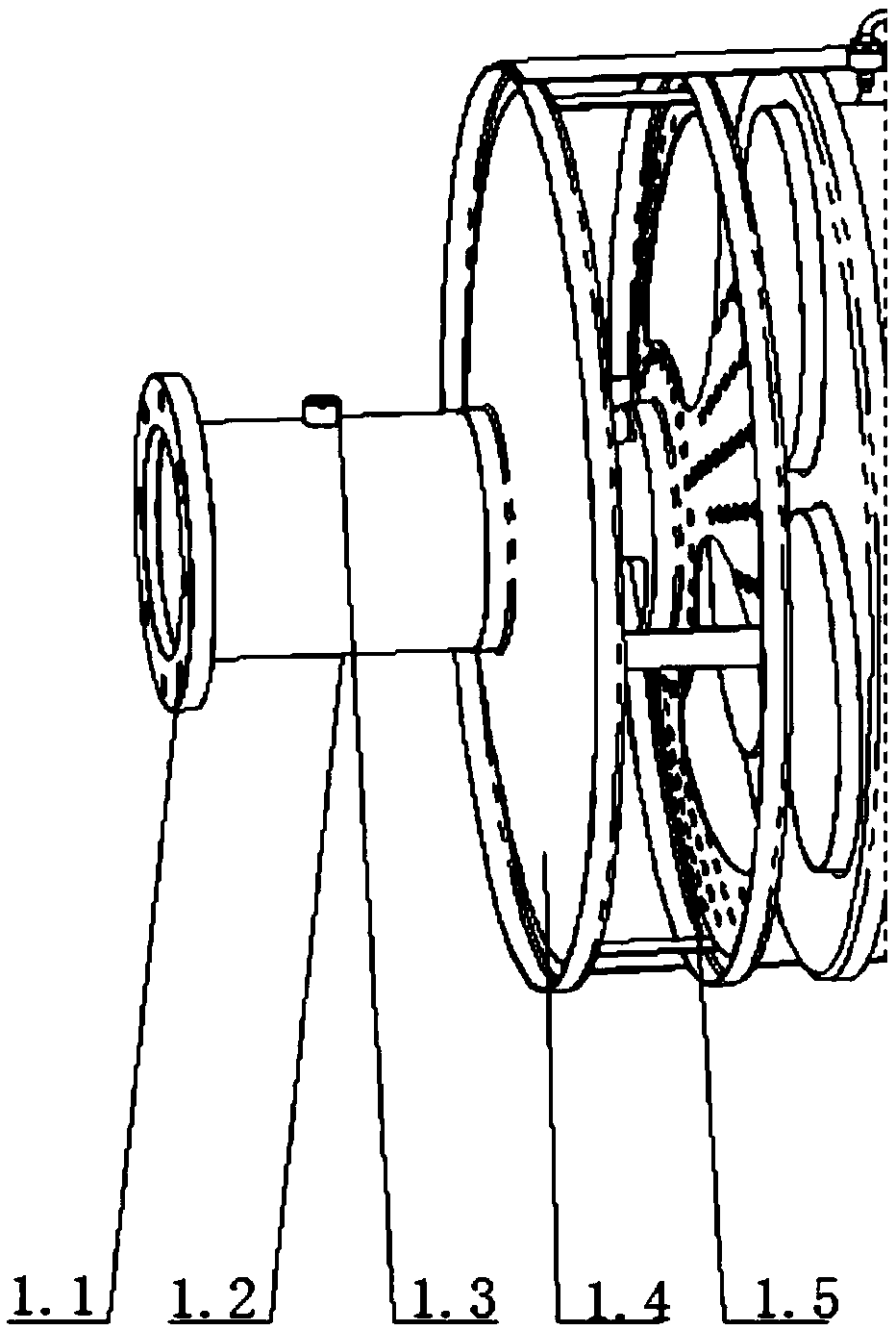

[0043] A compact large diesel engine exhaust gas treatment device, such as figure 2 As mentioned above, it includes an intake assembly 1, a DOC assembly 2, a DPF assembly 3, a mixing assembly 4, an SCR assembly 5 and an exhaust silencer assembly 6 connected in series;

[0044] Such as Figure 4-5 As shown, the mixing assembly includes a hollow mixing tube 4.4, and the mixing tube 4.4 is inserted through an inclined collecting plate 4.7. The upper part of the mixing tube 4.4 is located on the upper side of the collecting plate, and the lower part is located on the collecting plate. The lower side of 4.7; the upper part of the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com