Water reaction metal fuel cyclone punching power generation system

A metal fuel and power generation system technology, applied in gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of high fuel consumption, low efficiency, environmental pollution, etc., and achieve improved power generation efficiency, good chemical stability, and environmental pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

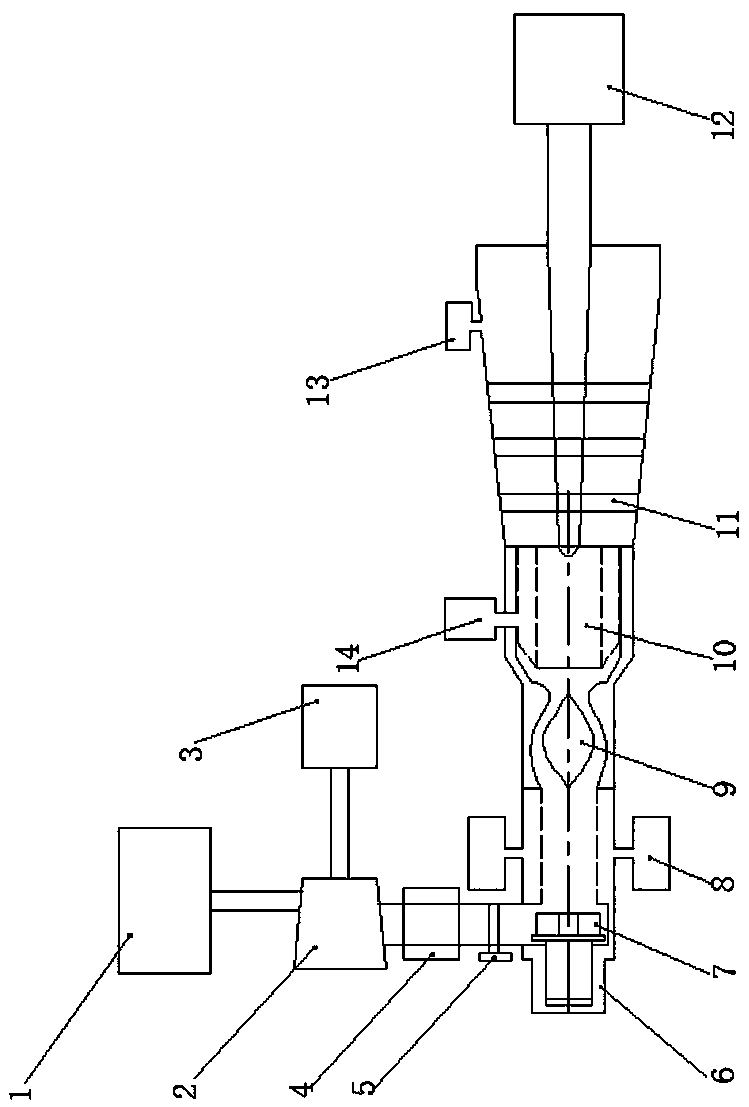

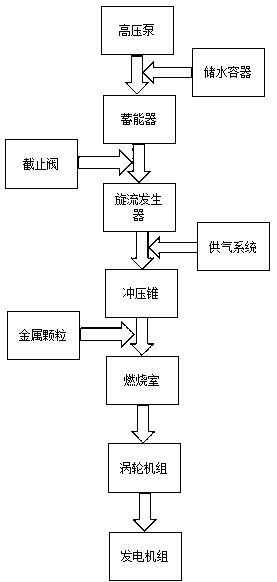

[0041] As shown in the figure, the power generation system of this embodiment includes a water storage container, a high-pressure pump, a high-pressure power system, a water pressure stabilization unit, a casing, a swirl generator, an air supply system, a stamping cone, a combustion chamber, a turbine unit, The generator set, exhaust gas treatment device, metal particle supply system, swirl generator, stamping cone, and combustion chamber are sequentially arranged in the casing. In this embodiment, the water storage container is a pool, the high-pressure power system is a diesel engine, and the waste gas treatment device is a waste gas collection device. In this embodiment, the exhaust gas collecting device is arranged at the end of the casing.

[0042] The water storage container, high-pressure pump, water pressure stabilization unit, and swirl generator are connected in sequence. The water in the water storage container can flow into the swirl generator of the casing after b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com