Graining machine fuel gas hot air circular drying system and temperature control method thereof

A technology of hot air circulation and drying system, applied in the directions of drying, dryer, drying gas arrangement, etc., can solve the problems of increased fuel consumption, unstable hot air temperature, heat loss, etc., and achieves reduction of heat loss and simple structure. , The effect of large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

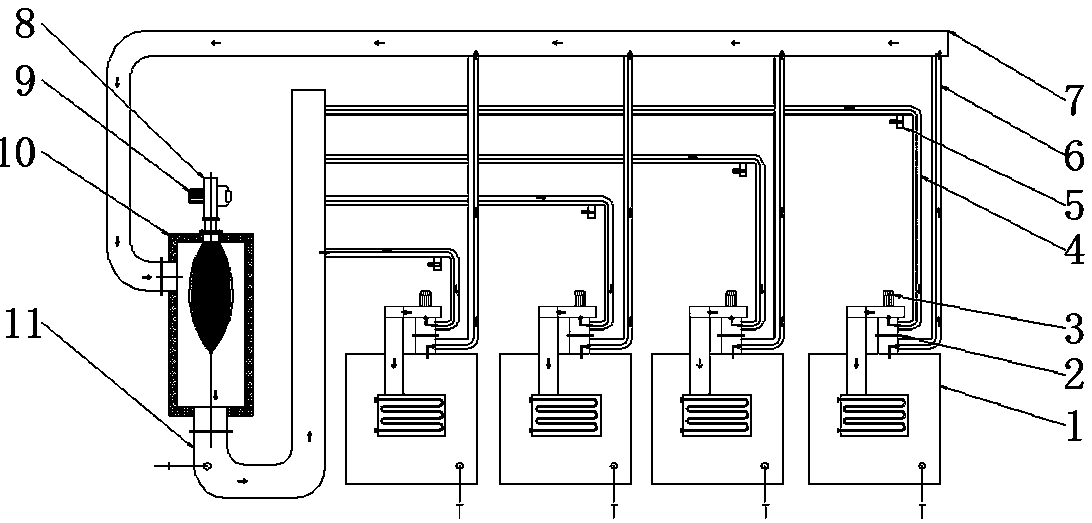

[0016] Such as Figure 1~3 As shown, a kneading machine gas hot air circulation drying system includes a hot blast stove 10, a natural gas burner 9 is arranged above the hot blast stove 10, an air inlet is arranged on one side of the hot blast stove 10, and an air outlet is arranged at the bottom of the hot blast stove , the air outlet is connected with a main smoke pipe 11, the main smoke pipe 11 is connected with a smoke distribution pipe 4 leading to the kneading machine oven 1, and the air inlet of the hot blast stove 10 is connected with a return air main pipe 7. The exhaust port of the machine oven is connected with the return air branch pipe 6 connected with the return air main pipe 7; this system is to mix the high-temperature flue gas generated by burning natural gas with the oven return air to cool down to the process temperature, and then send it to the The smoke distribution pipe is transported to the inlet of the circulation fan through the smoke distribution pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com