Self-aligned silicon germanium hbt device monitors the structure and process method of silicon germanium base region doping

A process method and self-alignment technology, applied in the manufacture of semiconductor devices, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of load effect, high cost, SIMS cannot reflect the distribution of device impurities, etc., and achieve easy implementation, The effect of simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

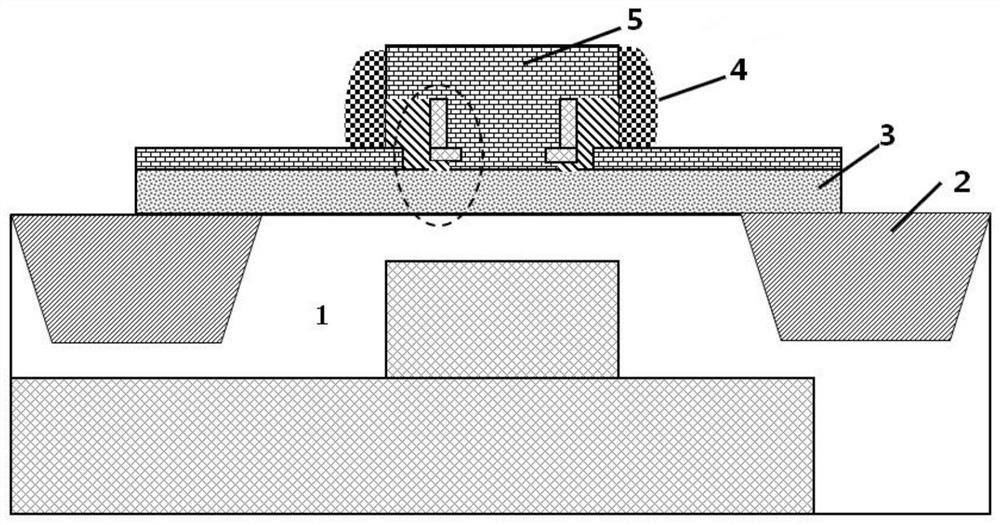

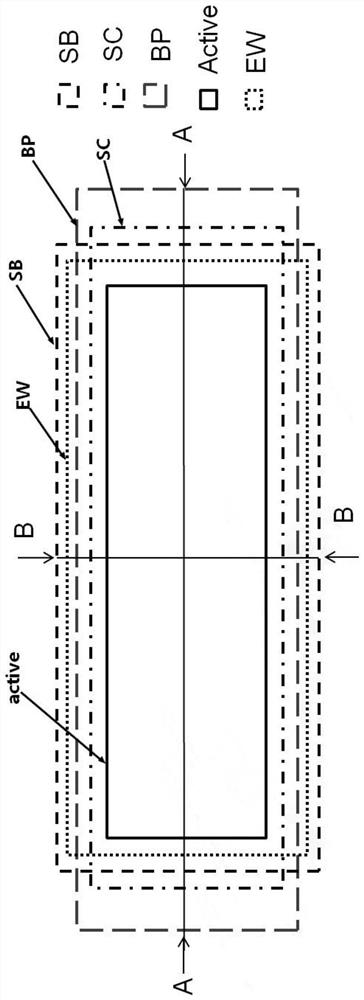

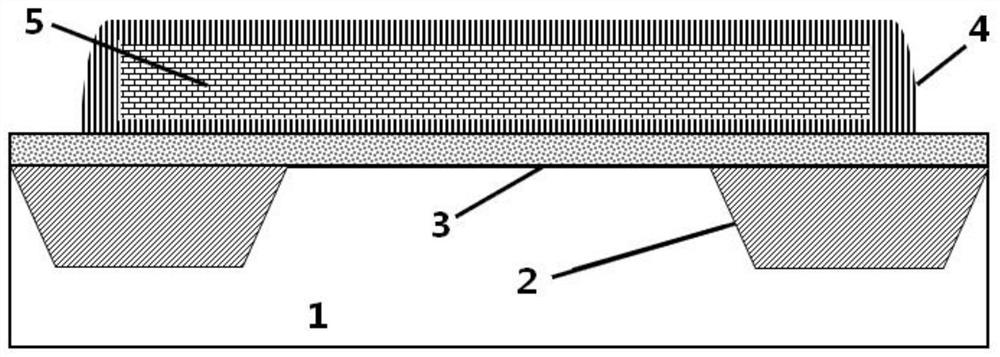

[0046] The self-aligned silicon germanium HBT device of the present invention monitors the test structure of the silicon germanium epitaxial layer doping, the layout of the test structure is as follows figure 2 shown, including:

[0047]The active area is a rectangle, and a rectangular etch-back protective layer SC, base polysilicon BP, sacrificial emitter window EW, and metal silicide barrier layer SB located outside the active area and surrounding the active area layer by layer ; Each of the layers is axially symmetrical with respect to the length and width of the active region.

[0048] In the length direction of the active region, that is, the AA direction from the inside to the outside, there are sacrificial emitter window EW, metal silicide barrier layer SB, etch-back protective layer SC and the boundary BP of the base polysilicon.

[0049] In the width direction of the active region, that is, the BB direction from the inside to the outside is the boundary of the etch-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com