Ultralow-temperature electrolyte solution as well as preparation method thereof, battery using ultralow-temperature electrolyte solution and preparation method thereof

An electrolyte and ultra-low temperature technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of increased battery internal resistance and low battery capacity retention, and achieves reduced internal resistance, reduced interface charge transfer impedance, and excellent Effects of Energy Density and Power Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

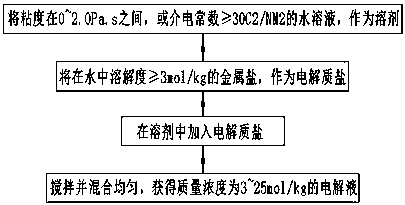

[0031] figure 1 A schematic flow chart of the preparation method of the ultra-low temperature electrolyte provided by the present invention, such as figure 1 As shown, the preparation method of the ultra-low temperature electrolyte includes: setting the viscosity at 0~2.0 Between, or dielectric constant ≥ 30 An aqueous solution, as a solvent; will have a solubility in water ≥ 3 Metal salt of metal salt, as electrolyte salt; Add electrolyte salt in solvent; Stir and mix well, obtain mass concentration and be 3~25 of electrolyte.

[0032] The ultra-low temperature electrolyte prepared by the preparation method of the ultra-low temperature electrolyte provided by the present invention includes: adding electrolyte salt in the solvent, and the obtained mass concentration is 3 ~ 25 electrolyte solution; wherein: the solvent is: the viscosity is 0~2.0 Between, or dielectric constant ≥ 30 single solvent, or a mixed solvent thereof; the electrolyte salt is: solubility in t...

Embodiment 1

[0038] First of all, in this embodiment one: the solvent is deionized water, and the electrolyte salt is lithium trifluoromethanesulfonate (LiOTf); secondly, in the fume hood, the quantitative trifluoromethanesulfonic acid Dissolve lithium in deionized water, stir for 30 minutes, and configure 1-11 Electrolyte solution to obtain electrolyte solution system 1.

[0039] In this example 1, the solid phase temperature of the obtained electrolyte system 1 is analyzed by differential scanning calorimetry (DSC), and it can be known that its solid phase temperature is -86°C; Table 1 (conductivity in mS / cm).

[0040]

[0041] It can be seen from the data in the table that in the electrolyte system 1 provided in the present embodiment 1, when the molar mass is 5 , the electrolyte has the highest conductivity.

Embodiment 2

[0043] First, in the second embodiment: the solvent is deionized water, and the electrolyte salt is lithium bis(trifluoromethanesulfonyl)imide (LiTFSI); Lithium (trifluoromethanesulfonyl)imide was dissolved in deionized water, stirred for 30 minutes, and configured as 3-14 electrolyte solution to obtain electrolyte solution system 2.

[0044] In this example 2, the solid phase temperature of the obtained electrolyte system 2 is analyzed by differential scanning calorimetry (DSC), and it can be known that the solid phase temperature is -86°C; Table 2 (conductivity in mS / cm).

[0045]

[0046] It can be seen from the data in the table that in the electrolyte system two provided in this embodiment two, when the molar mass is 8 , the electrolyte has the highest conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com