Manufacture method of dried sturgeon marrow

A production method, the technology of Sturgeon Ichthyosaurus, which is applied in the fields of dry preservation of meat/fish, food drying, food science, etc., can solve the problems of long processing time and difficult control, and achieve simple production, easy operation, and shortened processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Material selection for S1: choose the sturgeon dragon tendon stored at -20°C, slow down for 1 hour at 0-4°C;

[0030] S2 cut into sections: cut the dragon tendon of sturgeon obtained in step S1 into small sections with a length of 5 cm;

[0031] S3 ripening: boil the sturgeon tendon obtained in step S2 at 100°C for 1.5 hours, take out the sturgeon tendon and drain;

[0032] S4 edge trimming: cut off the broken part of the sturgeon dragon tendon obtained in step S3 due to boiling, and keep the complete shape of the sturgeon dragon tendon;

[0033] S5 drying: drying the dragon tendon of sturgeon obtained in step S4 for 100 min at a temperature of 80° C., a humidity of 0%, and a wind speed of 25 m / s;

[0034] S6 packaging: vacuum-packing the dragon tendon of sturgeon obtained in step S5 to obtain dried dragon tendon of sturgeon.

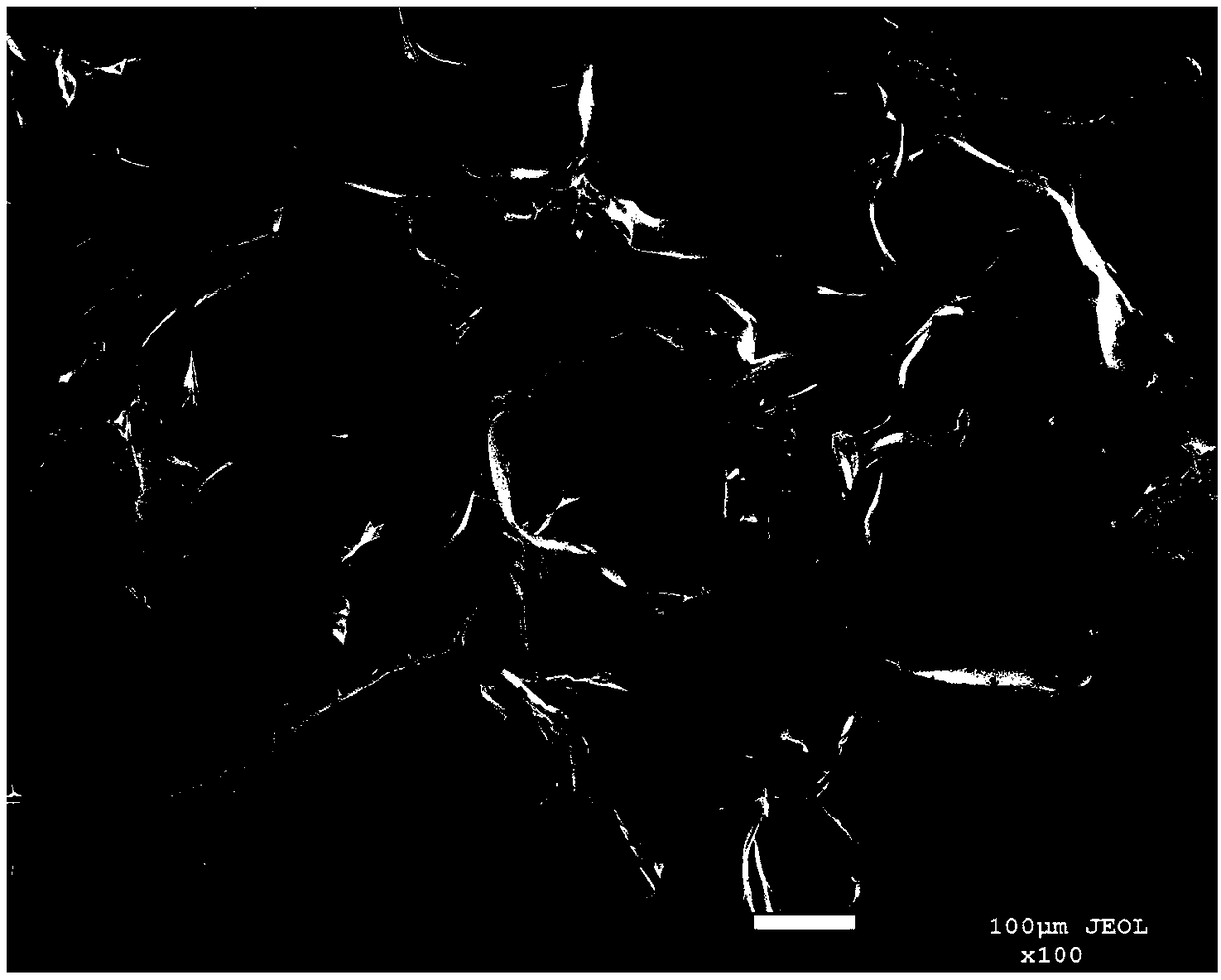

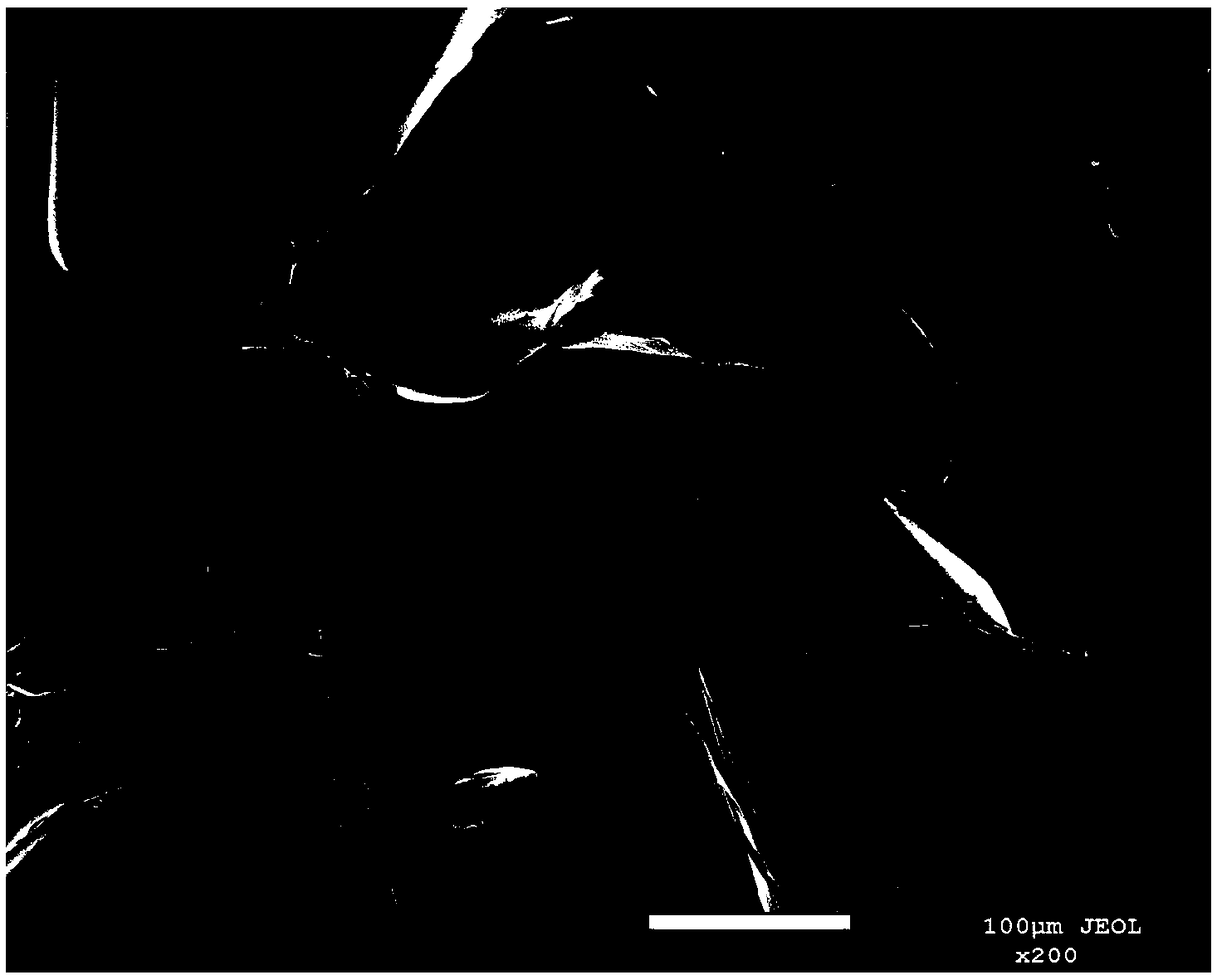

[0035] After soaking at room temperature for 4 hours, the dried tendon of sturgeon produced in this example was subjected to microstructure de...

Embodiment 2

[0037] Material selection for S1: choose the sturgeon dragon tendon stored at -20°C, slow down for 1 hour at 0-4°C;

[0038] S2 cut into sections: cut the sturgeon dragon tendon obtained in step S1 into small sections with a length of 8 cm;

[0039] S3 ripening: boil the sturgeon tendon obtained in step S2 at 90°C for 6 hours, take out the sturgeon tendon and drain;

[0040] S4 edge trimming: cut off the scattered parts of the sturgeon dragon tendon obtained in step S3;

[0041] S5 drying: drying the dragon tendon of sturgeon obtained in step S4 for 150 min at a temperature of 60° C., a humidity of 0%, and a wind speed of 16 m / s;

[0042] S6 packaging: vacuum-packing the dragon tendon of sturgeon obtained in step S5 to obtain dried dragon tendon of sturgeon.

[0043] After the dried sturgeon tendons prepared in this example were soaked at room temperature for 4 hours, the texture was determined with the sturgeon tendons obtained in step S3 of this example (i.e., the sturgeon...

Embodiment 3

[0047] S1 material selection: select fresh sturgeon tendon with complete shape;

[0048] S2 cut into sections: cut the dragon tendon of sturgeon obtained in step S1 into small sections with a length of 6 cm;

[0049] S3 ripening: boil the sturgeon tendon obtained in step S2 at 80°C for 10 hours, take out the sturgeon tendon and drain;

[0050] S4 edge trimming: cut off the scattered parts of the sturgeon dragon tendon obtained in step S3;

[0051] S5 drying: drying the dragon tendon of sturgeon obtained in step S4 for 240 minutes at a temperature of 80° C., a humidity of 20%, and a wind speed of 8 m / s;

[0052] S6 packaging: vacuum-packing the dragon tendon of sturgeon obtained in step S5 to obtain dried dragon tendon of sturgeon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com