Preparation method of fermented vegetarian product

A technology of fermented products and products, which is applied in the field of preparation of probiotic fermented plant-based products, can solve the problems of long fermentation time, no production of probiotic metabolites, fast fermentation speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] According to an embodiment of the present invention, there is provided a method for preparing a fermented vegetarian product, the method comprising:

[0024] a) The pretreatment step of raw materials: the raw materials used are selected from beans, grains, nuts, vegetables, fruits or a combination thereof, wherein the preferred pretreatment is for beans or grains, the pretreatment is boiling 5-15 Minutes, then soak in boiling water for 20-40 minutes, and then peel; for nuts, the pretreatment is roasting at 125-130 degrees Celsius for 1.5-2.5 hours and then peeling; for vegetables or fruits, the pretreatment is cleaning And pick

[0025] b) a beating and filtering step, mixing the pretreated raw materials with water for beating treatment to obtain a mixed slurry, and filtering the mixed slurry to obtain a raw material mixed liquid;

[0026] c) The step of adding a carbon source, adding a carbon source to the raw material mixture, and stirring and dissolving at 50-60° C. for 20...

Embodiment

[0037] The pretreatment of raw materials can adopt methods well known in the art. For example, steps such as soaking, boiling, baking, peeling, etc. can be taken, and the pretreated raw materials are suitable for the subsequent beating and filtering steps.

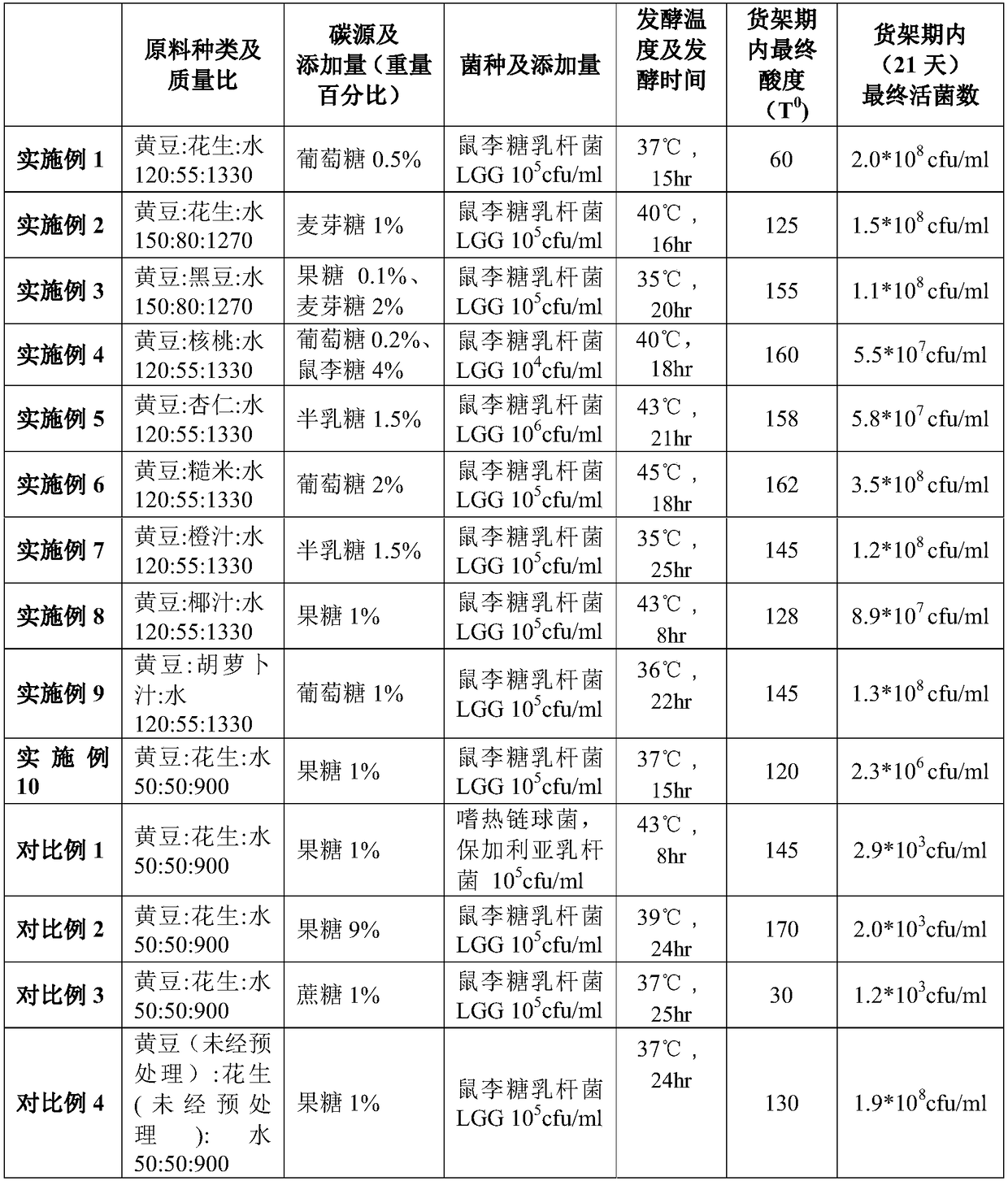

[0038] Examples 1-10 and Comparative Examples 1-4 were implemented according to the steps of the following method, and the details are as follows:

[0039] After the raw materials are pretreated, they are mixed with water in a certain mass ratio to obtain a mixed slurry. The mixed slurry is coarsely filtered and filtered with 100 meshes to obtain a raw material mixture; a carbon source is added to the raw material mixture and kept at 60°C Stir for 20 minutes; heat the raw material mixture with carbon source to 65°C, homogenize at 16-20MPa, and then sterilize at 90-95°C for 20 minutes; cool the raw material mixture to 43°C, Inoculate the bacteria used for fermentation under conditions (the inoculum amount is 10 3 ~10 7 cfu / ml);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com