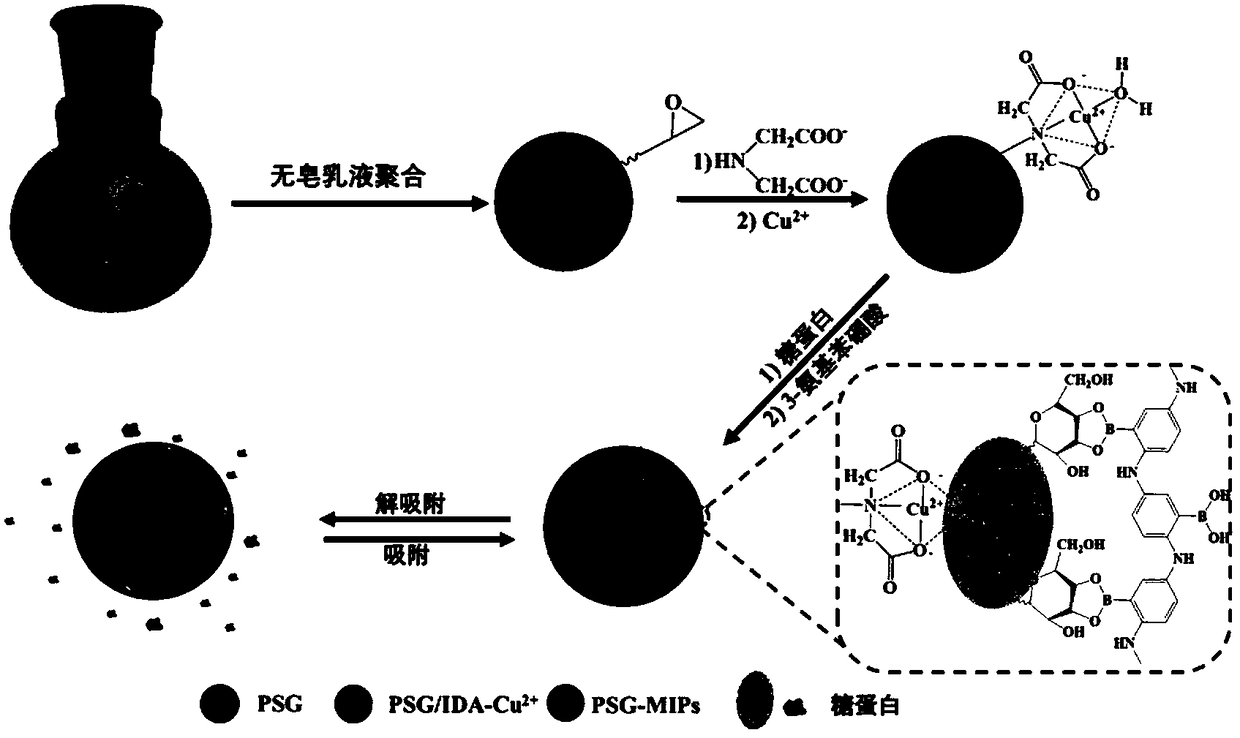

Double-recognition locus glycoprotein surface imprinting nano material as well as preparation method and application thereof

A nanomaterial, surface imprinting technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor adsorption effect of boron affinity recognition, cumbersome preparation process, etc., to achieve selective affinity recognition and easy raw materials. Obtain and improve the effect of weak binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

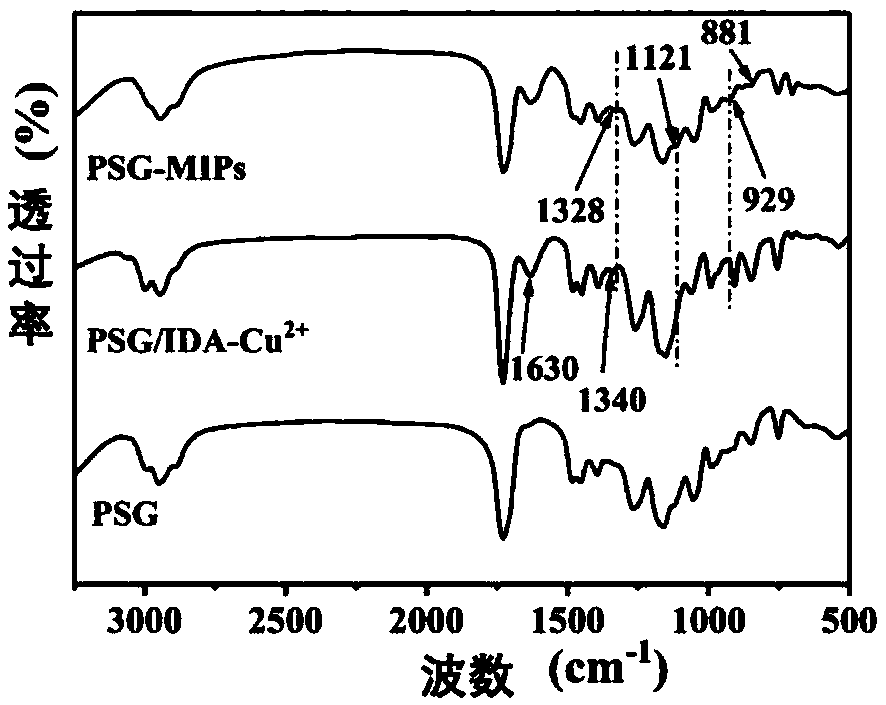

[0046] (1) Preparation of polyglycidyl methacrylate (PSG) nanoparticle dispersion:

[0047] Add 1.5 mL of GMA, 0.05 mL of DVB and 0.2 mL of St into a 250 mL three-neck flask, then add 100 mL of double-distilled water and insert a thermometer and a nitrogen tube, and continue stirring and heating under a nitrogen atmosphere. When the temperature reached 71 °C, 1.5 mL of 0.03 g / mL potassium persulfate solution was added to initiate polymerization, and the reaction was continued for 6.0 h. After the reaction, the product was separated by centrifugation, washed three times with ethanol and double-distilled water, and then dispersed in 100 mL of double-distilled water to obtain a polyglycidyl methacrylate (PSG) nanoparticle dispersion for later use.

[0048] (2) Surface chelated Cu 2+ Polyglycidyl methacrylate nanoparticles (PSG / IDA-Cu 2+ ) preparation:

[0049] Add 1.0 g IDA and 1.0 g NaOH to a 250 mL three-necked flask, and then add 100 mL of the polyglycidyl methacrylate (PSG...

Embodiment 2

[0057] (1) Preparation of polyglycidyl methacrylate (PSG) nanoparticle dispersion:

[0058] Add 2.348 mL of GMA, 0.064 mL of DVB and 0.46 mL of St into a 250 mL three-neck flask, then add 100 mL of double-distilled water, insert a thermometer and a nitrogen tube, and continue stirring and heating under a nitrogen atmosphere. When the temperature reached 71 °C, 2.0 mL of 0.03 g / mL potassium persulfate solution was added to initiate polymerization, and the reaction was carried out for 8.0 h. After the reaction, the product was separated by centrifugation, and the product was washed three times with ethanol and double distilled water, and then the product was dispersed in 100 mL double distilled water, separated, and the product was washed three times with ethanol and double distilled water, and then the product Disperse in 100 mL double-distilled water to obtain a polyglycidyl methacrylate (PSG) nanoparticle dispersion, which is set aside.

[0059] (2) Surface chelated Cu 2+ P...

Embodiment 3

[0064] (1) Preparation of polyglycidyl methacrylate (PSG) nanoparticle dispersion:

[0065] Add 3.0 mL of GMA, 1.0 mL of DVB and 0.6 mL of St into a 250 mL three-necked flask, then add 100 mL of double-distilled water and insert a thermometer and a nitrogen tube, and continue stirring and heating under a nitrogen atmosphere. When the temperature reached 71 °C, 2.5 mL of 0.03 g / mL potassium persulfate solution was added to initiate polymerization, and the reaction was carried out for 9.0 h. After the reaction, the product was separated by centrifugation, washed three times with ethanol and double distilled water, and then the product was dispersed in 100 mL double distilled water to obtain a polyglycidyl methacrylate (PSG) nanoparticle dispersion for future use.

[0066] (2) Surface chelated Cu 2+ Polyglycidyl methacrylate nanoparticles (PSG / IDA-Cu 2+ ) preparation:

[0067] 2.5 g IDA and 1.5 g NaOH were added to a 250 mL three-neck flask, followed by 100 mL of the polyglyci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com