Nutritional rice production control system

A technology for production control and nutritional rice, applied in the fields of application, grain processing, agriculture, etc., can solve the problems of low processing efficiency, low rice yield, etc., to overcome the low processing efficiency, overcome the low rice yield, overall Scientific and rational effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

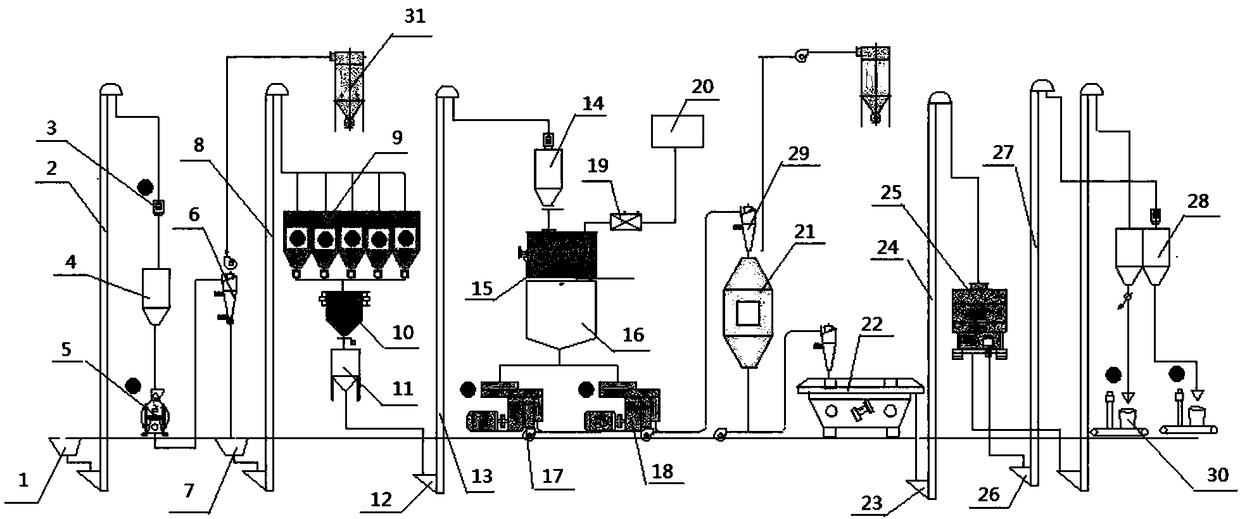

[0010] Example: see attached figure 1 , the nutritional rice production control system is provided with a primary feed pool 1, the primary feed pool is filled with rice, kudzu root, black rice, purple sweet potato, and buckwheat, and the rice, kudzu root, black rice, purple sweet potato, and buckwheat pass through the first elevator 2. After lifting, go through the electromagnet 3 to remove iron and enter the pulverizer bin 4. After being pulverized by the pulverizer 5, it enters the first rice sieve 6, and then enters the secondary material pool 7, and the secondary material pool passes through the first rice sieve. The second hoist 8 is connected with a rice milling unit 9, the second rice sieve 10 is connected under the rice milling unit, and a buffer bin 11 is arranged below the second rice sieve, and the buffer bin 11 is connected to the three-stage feed pool through a pipeline. 12 is connected, and the three-stage material pool is connected with a permanent magnet barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com