Method for preparing wave-absorbing material by means of nickel slag and wave-absorbing material

A technology of wave absorbing material and nickel slag, which is applied in the fields of magnetic materials, inorganic material magnetism, chemical instruments and methods, etc., can solve the problems of low synthesis amount, easy agglomeration of wave absorbing materials, and inability to mass-produce, etc. Avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

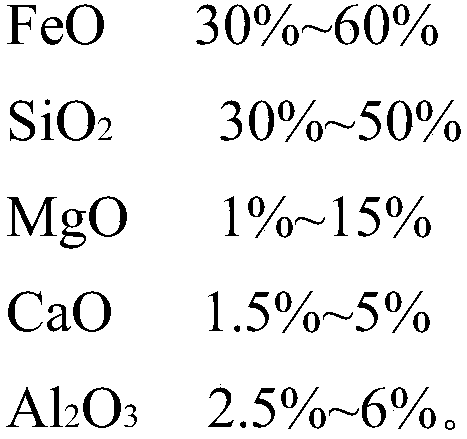

[0062] The present invention also provides the wave absorbing material obtained by the above preparation method, and the wave absorbing material includes the following raw materials composition by mass percentage:

[0063]

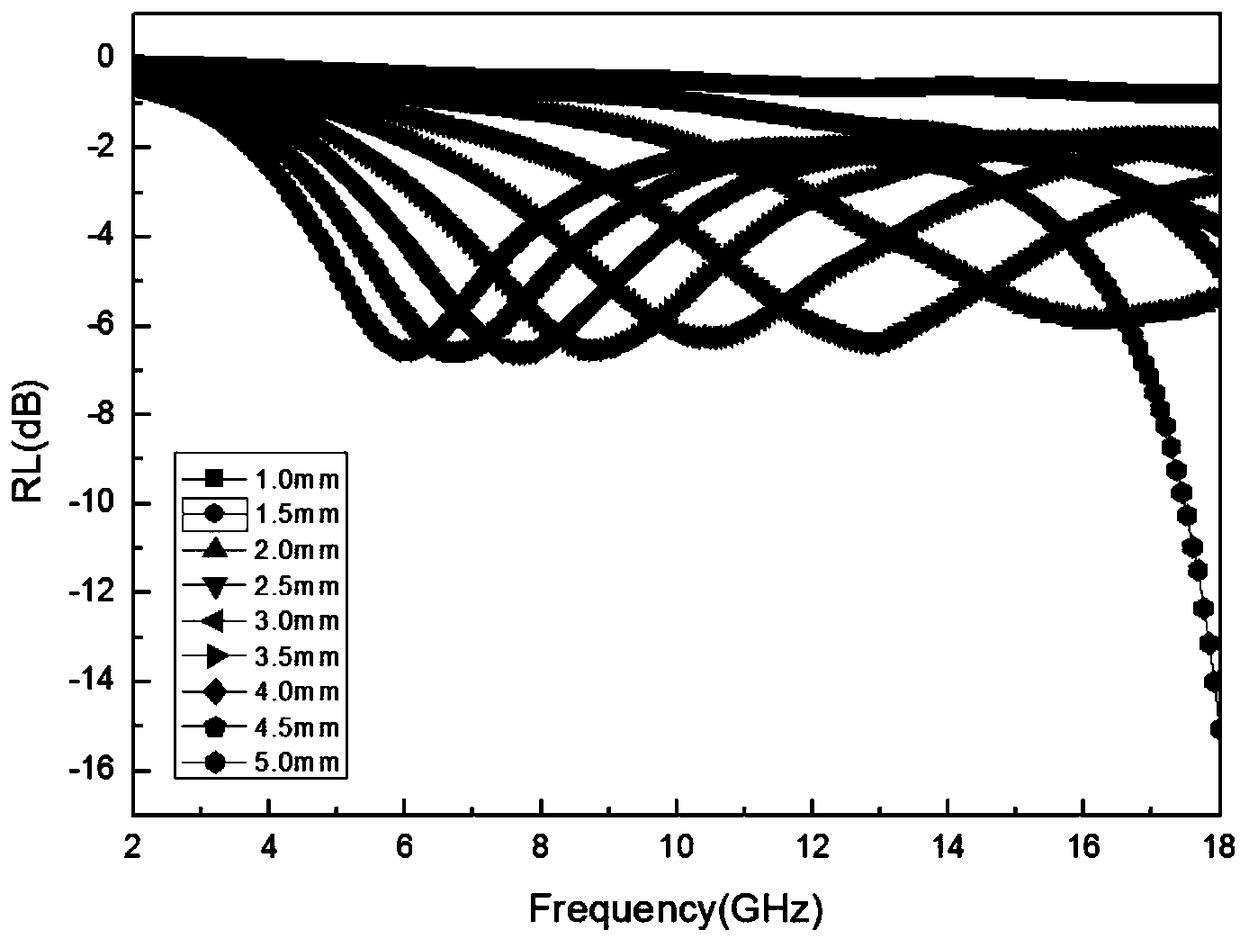

[0064] The particle size of the absorbing material is 70-150 nm.

[0065] In the present invention, the particle size of the wave absorbing material is preferably 90-130 nm, more preferably 100-120 nm.

Embodiment 1

[0068] Nickel slag is water quenched nickel slag of flash furnace

[0069] The specific composition is:

[0070]

[0071] Other: 1%.

[0072] After breaking the nickel slag, use a 200 mesh sieve ( 3 O 4 The particle size of the nano crystals is 70 nm to 90 nm, and the wave absorbing material is prepared.

Embodiment 2

[0074] Nickel slag is flash furnace water quenched nickel slag, and its specific composition is:

[0075]

[0076] Other: 1%.

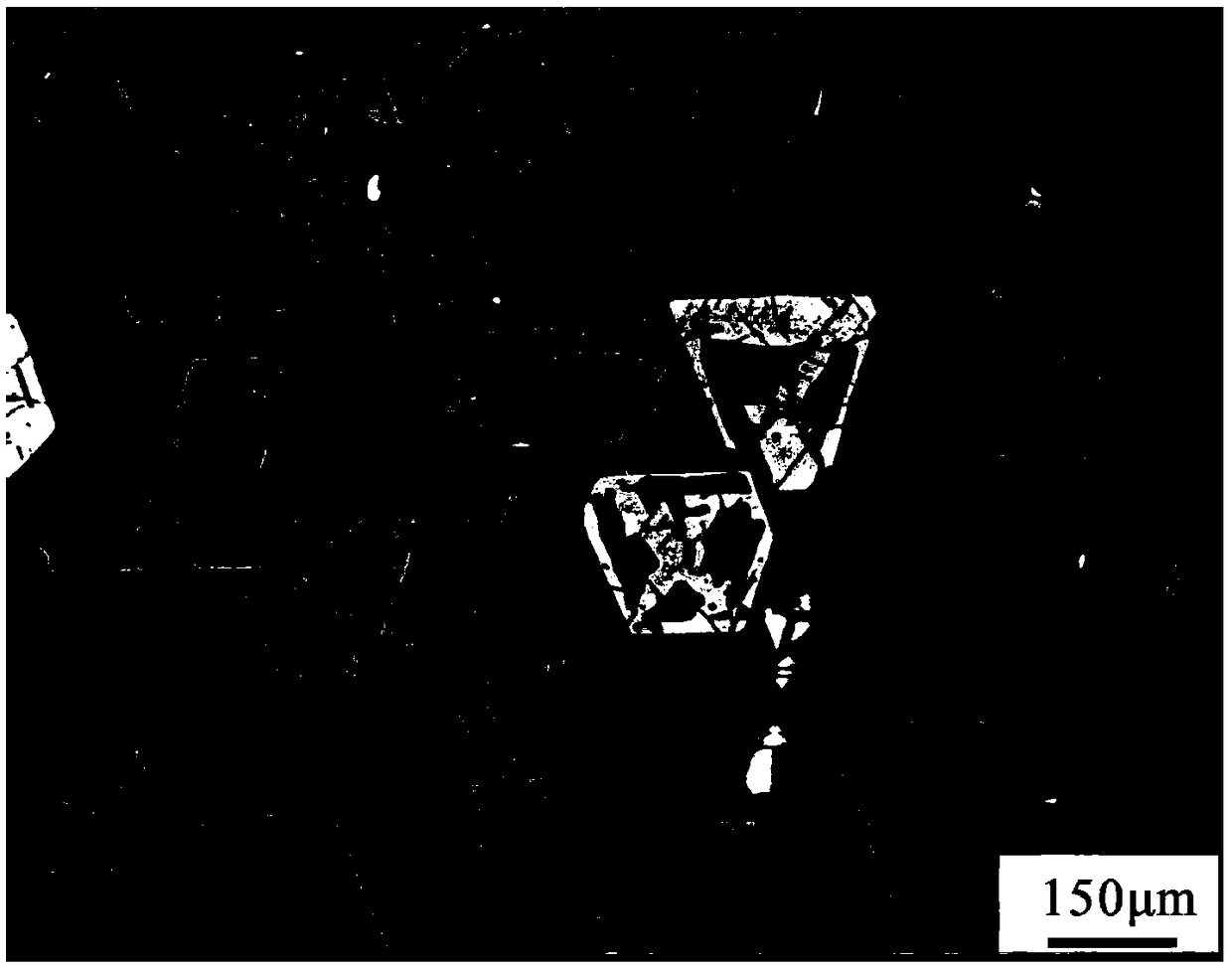

[0077] After breaking the nickel slag, use a 200 mesh sieve ( figure 1 Shown). The oxidized modified nickel slag is crushed to below 200 mesh, and placed in a magnetic separator with a magnetic field strength of 150mT for magnetic separation. Place the magnetic substance in a ball mill, add ethanol as a dispersant, and grind for 24 hours until Fe 3 O 4 The particle size of the nanocrystal is 100nm-120nm, and the wave absorbing material is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com