Preparing technology of solid polymer water electrolysis oxygen evolution catalyst iridium oxide

A technology of solid polymer and oxygen catalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, electrolysis process, etc. low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

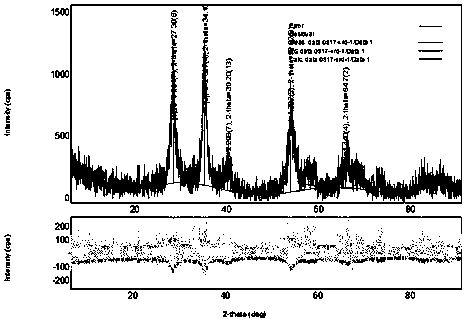

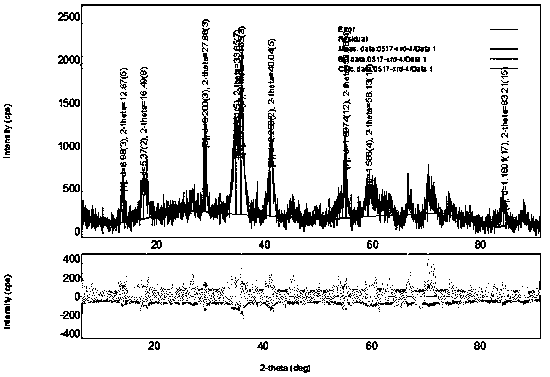

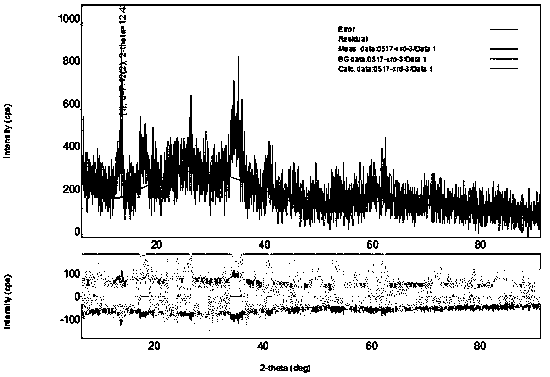

Image

Examples

Embodiment 1

[0029] Take 1g of iridium salt, add 5g of magnesium salt and stir evenly, then add 50g of distilled water to dissolve completely. Stir continuously for 1 hour during heating in a water bath at 50°C to disperse the reaction evenly, dry it, then put it in a preheated oven for calcination at 600°C for 1 hour, take it out and cool it to room temperature, and finally wash it with suction to obtain the finished iridium oxide I.

Embodiment 2

[0031] Take 1g of iridium salt, add 13g of magnesium salt and stir evenly, then add 70g of distilled water to dissolve completely. Stir continuously for 5 hours during the heating process in a water bath at 80°C to make the reaction disperse evenly, dry it, then put it into a preheated oven for calcination at 300°C for 5 hours, take it out and cool it to room temperature, and finally wash it with suction to obtain the finished iridium oxide I.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com