Nitrogen cycle refrigeration carbon monoxide cryogenic separation device and technology

A technology of cryogenic separation and carbon monoxide, applied in the field of cryogenic equipment, can solve the problems of complex process, high energy consumption, defects in process and energy consumption, etc., and achieve the effect of saving energy consumption and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated and described below with reference to the accompanying drawings and specific embodiments. The technical features of the various embodiments of the present invention can be combined correspondingly on the premise that there is no conflict with each other.

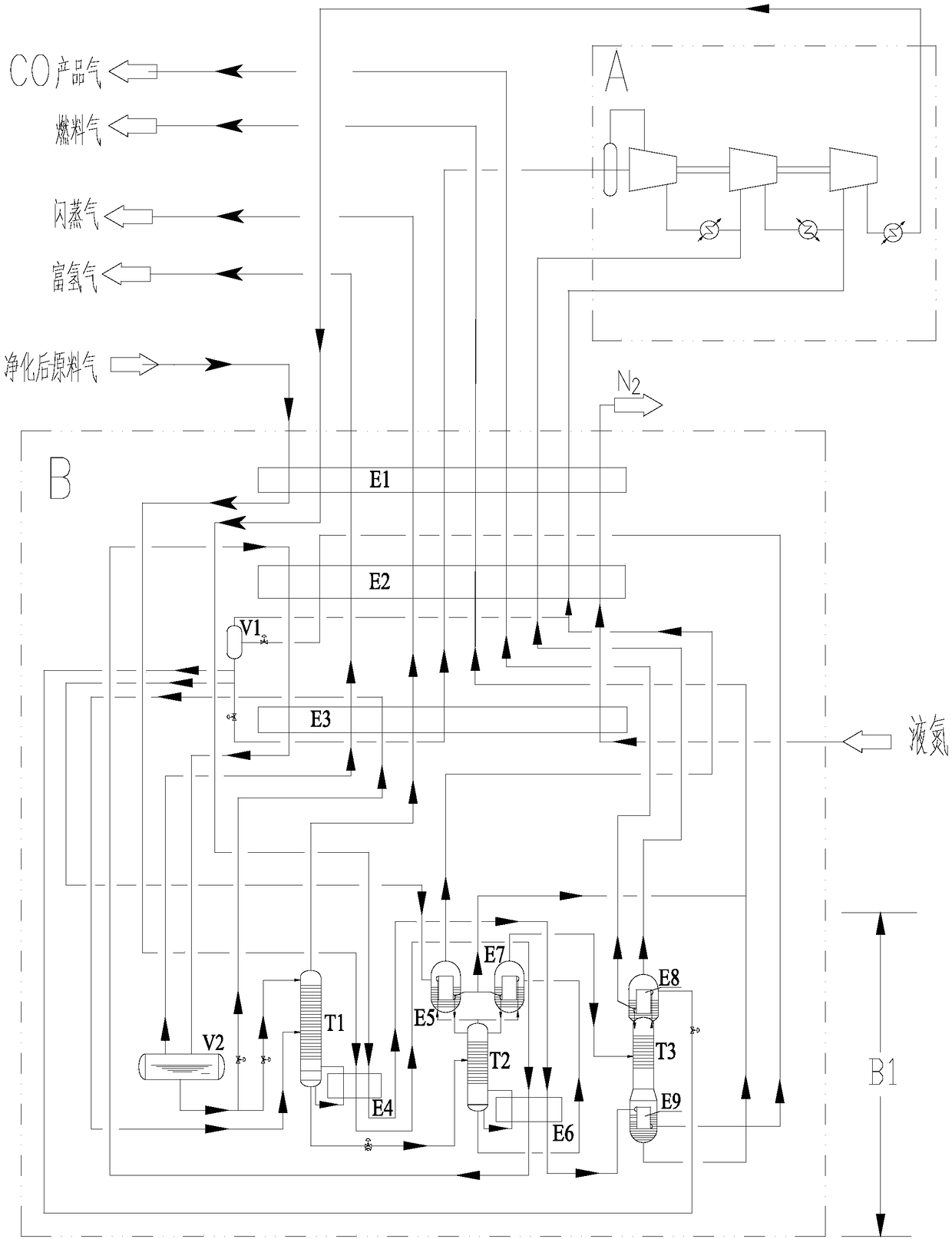

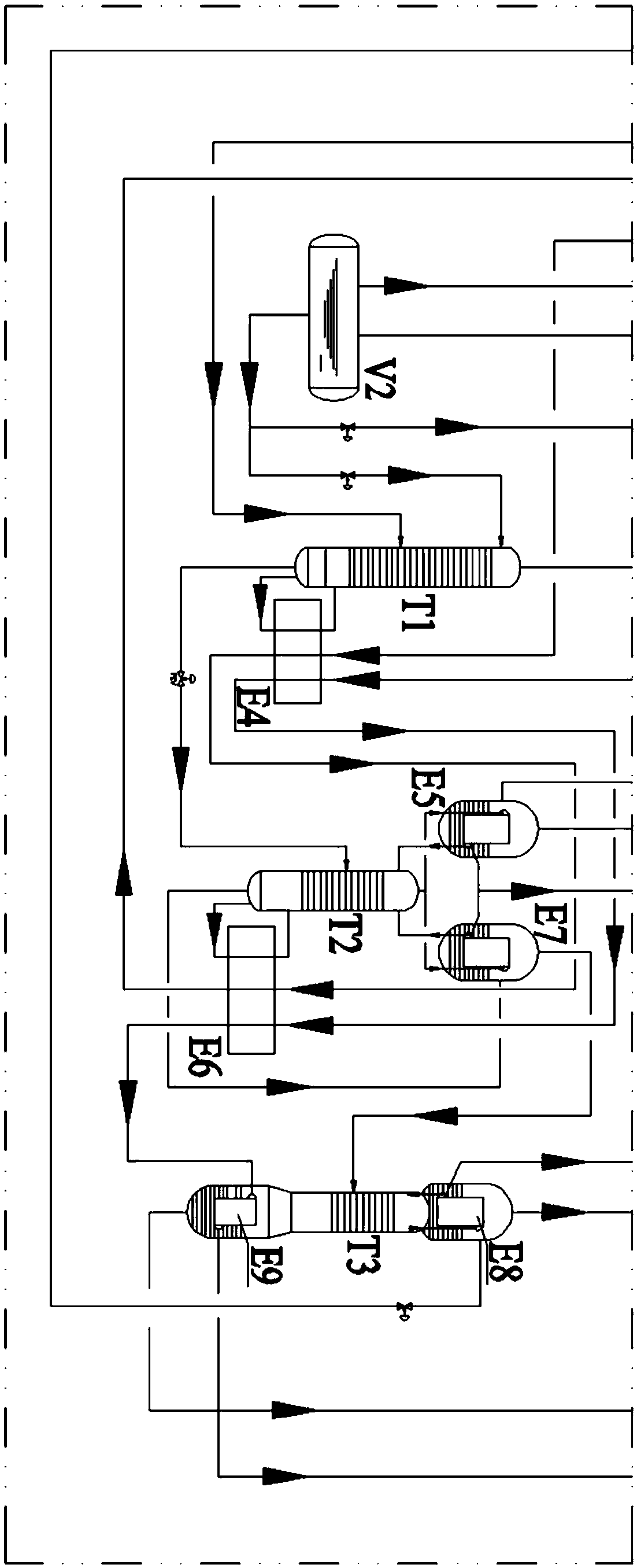

[0026] like figure 1 As shown, a nitrogen cycle refrigeration device for cryogenic separation of carbon monoxide gas mainly includes a nitrogen compressor system A and a cold box separation unit B. The nitrogen compressor system A uses a three-stage compressor to provide cooling capacity for the entire cold box separation unit B. The main body of the cold box separation unit B is a cold box, and the cold box is provided with a plate-fin heat exchanger, a demethanizer condenser E8, a demethanizer reboiler E9, a gas-liquid separation tank V1, and a hydrogen-rich flash tank. V2, stripper T1, denitrogenation tower T2 and demethanizer T3. The plate-fin heat exchanger incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com