A method for characterizing microcorrosion characteristics of enamel-coated low-carbon steel surfaces using wire beam electrodes

A technology of tow electrode and low carbon steel, which is applied in the field of metal electrochemical micro-testing, can solve the problems of tow electrode characterizing the corrosion resistance of metal alloy corrosion-resistant nano-enamel coating surface micro-area corrosion characteristics, etc., and achieves the convenience of continuous monitoring and automation. High, measurement accuracy and reliability results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

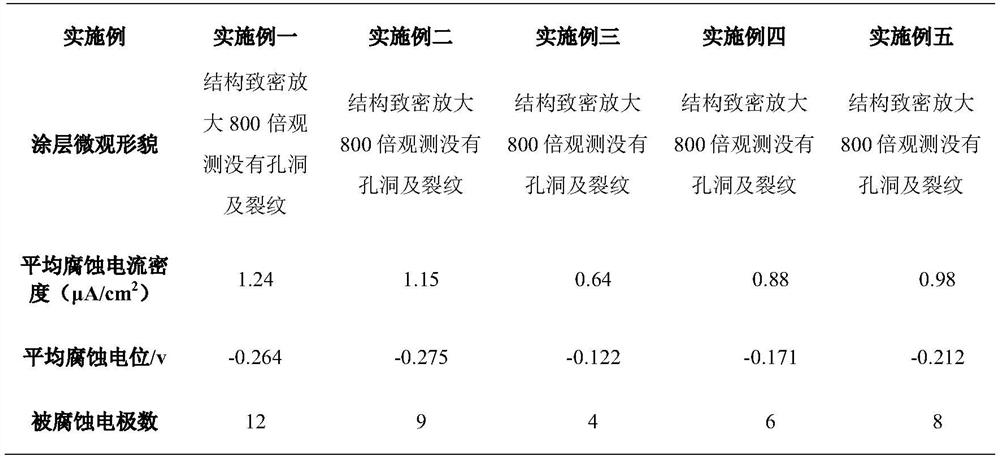

Embodiment 1

[0022] In this embodiment, a method for characterizing micro-area corrosion characteristics of a low-carbon steel surface coated with an enamel layer by using a wire beam electrode comprises the following steps:

[0023] a. Preparation of enamel sample: prepare enamel powder with a set composition formula to obtain nano-sized enamel powder with a particle size diameter of 10-900 microns; combine a certain amount of cobalt oxide and a certain amount of nickel oxide together Mix and fully stir with a certain amount of ethanol and nano-enamel powder to make a slurry with a certain viscosity, which is used as a sintered coating material for later use, wherein the amount of ethanol added is 10% of the mass of the slurry, and cobalt oxide and oxide The amount of nickel added is 1.5% and 3% of the mass of the slurry respectively, and the viscosity of the slurry is controlled to be 6Pa·s, and then the slurry after stirring is taken out, and then the slurry is evenly coated on a low-car...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, especially in that:

[0033] In this embodiment, a method for characterizing micro-area corrosion characteristics of a low-carbon steel surface coated with an enamel layer by using a wire beam electrode comprises the following steps:

[0034]a. Preparation of enamel sample: prepare enamel powder with a set composition formula to obtain nano-sized enamel powder with a particle size diameter of 10-900 microns; combine a certain amount of cobalt oxide and a certain amount of nickel oxide together Mix and fully stir with a certain amount of ethanol and nano-enamel powder to make a slurry with a certain viscosity, which is used as a sintered coating material for later use, wherein the amount of ethanol added is 10% of the mass of the slurry, and cobalt oxide and oxide The amount of nickel added is 1.5% and 3% of the mass of the slurry respectively, and the viscosity of the slurry is controlled to be 6Pa·s, and then the s...

Embodiment 3

[0042] This embodiment is basically the same as the previous embodiment, and the special features are:

[0043] In this embodiment, a method for characterizing micro-area corrosion characteristics of a low-carbon steel surface coated with an enamel layer by using a wire beam electrode comprises the following steps:

[0044] a. Preparation of enamel sample: prepare enamel powder with a set composition formula to obtain nano-sized enamel powder with a particle size diameter of 10-900 microns; combine a certain amount of cobalt oxide and a certain amount of nickel oxide together Mix and fully stir with a certain amount of ethanol and nano-enamel powder to make a slurry with a certain viscosity, which is used as a sintered coating material for later use, wherein the amount of ethanol added is 10% of the mass of the slurry, and cobalt oxide and oxide The amount of nickel added is 1.5% and 3% of the mass of the slurry respectively, and the viscosity of the slurry is controlled to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com