Detergent composition

A composition and detergent technology, applied in the direction of detergent composition, organic detergent composition, surface active detergent composition, etc., can solve problems affecting product experience, liquid product stratification, and difficulty in dissolving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

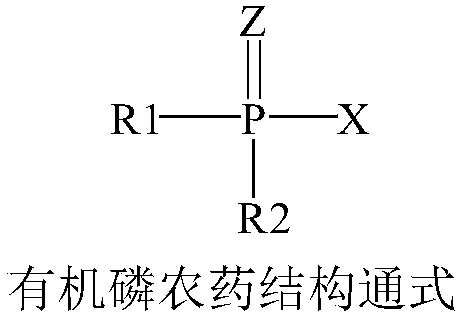

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-2

[0280] Liquid detergent compositions A, B, C, A' and B' were formulated according to the composition of Table 1 below.

[0281] Each component and performance of liquid detergent composition A, B, C and A', B' in table 1 embodiment 1-3, comparative example 1-2

[0282]

[0283]

[0284] As can be seen from Table 1, the detergent composition of embodiment 1-3 has higher enzymatic activity under the environment of high content anionic surfactant, especially pesticide degrading enzyme has high activity retention rate. This is benefited from two aspects, and one is that chelating agent is added among the embodiment 1-3, and another is that among the embodiment 1-3, suitable enzyme preparation has been added. But compared with using GLDA as chelating agent in embodiment 1, in embodiment 3, using EDTA as chelating agent, under high temperature, the activity of pesticide degrading enzyme becomes lower, shows that the selection of chelating agent keeps very little to the activit...

Embodiment 1 and comparative example 3-5

[0286] Liquid detergent compositions A, C', D' and E' were formulated according to the composition of Table 2 below.

[0287] Each component and performance of liquid detergent composition A, C', D' and E' of table 2 embodiment 1 and comparative example 3-5

[0288]

[0289]

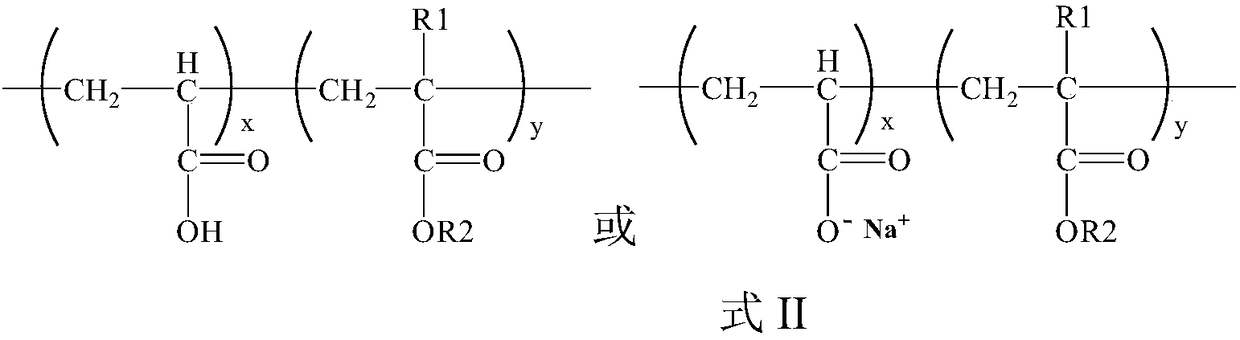

[0290] As can be seen from Table 2, Example 1 solves the problem that the detergent composition with a high content of enzyme preparation (the addition of enzyme preparation in the liquid detergent composition is greater than or equal to 0.5%) easily leads to a rise in viscosity after experiencing a high temperature environment. high defect. In all examples and comparative examples in the detailed description of the invention, the initial viscosity of all compositions was adjusted to 2500cP. However, as can be seen from Comparative Example 3, without adding ST2S and Thixome S-9, the initial state viscosity of the composition at -25°C is 2519cP, while the 45°C-viscosity change rate at -25°C is 3.2,...

Embodiment 1、 comparative example 4 and comparative example 6

[0292] Liquid detergent compositions A, D' and F' were formulated according to the composition of Table 3 below.

[0293] Each component and performance of liquid detergent composition A, D' and F' of table 3 embodiment 1, comparative example 4 and comparative example 6

[0294]

[0295]

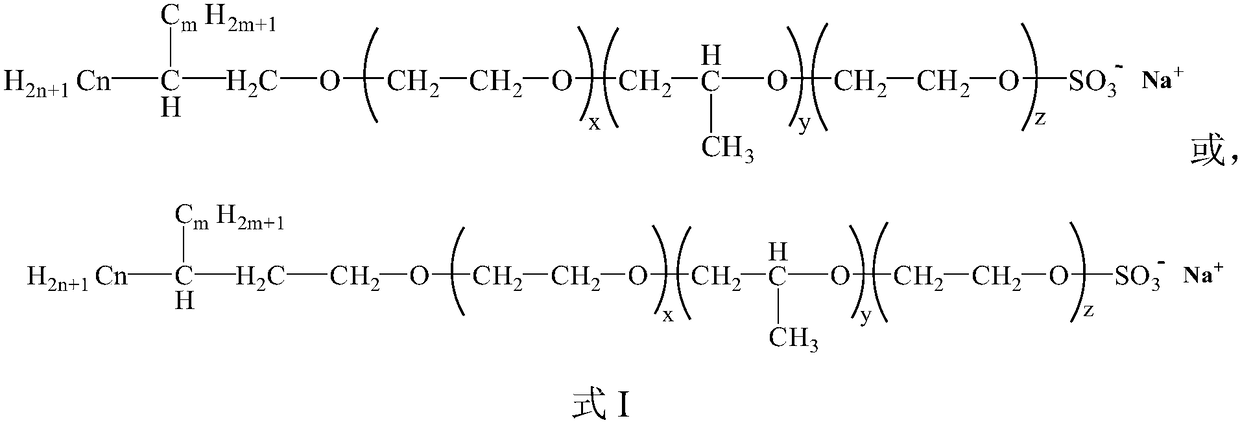

[0296] As can be seen from Table 3, in Example 1, the isomeric fatty alcohol polyoxyethylene ether sulfate sodium has a special branched chain structure, which is conducive to impelling the surfactant to form a structure in the environment of high surfactant concentration or high protein concentration Simple micelle structure, rather than complicated micelle structure, specifically, utilize the steric hindrance characteristic of carbon chain branch to impel the micelle of liquid detergent composition to form the structure of spherical micelle or rod micelle, and Not a lamellar or worm-like micellar structure. It can be seen from the results in Table 3 that when using straight-chain AE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com