In-situ repair structure for municipal household waste landfill and method thereof

A technology for in-situ restoration of municipal solid waste, applied in the structural field of in-situ restoration of municipal solid waste landfills, can solve problems such as high moisture content, palliative treatment but not root cause, stale waste that cannot fully meet the incineration standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

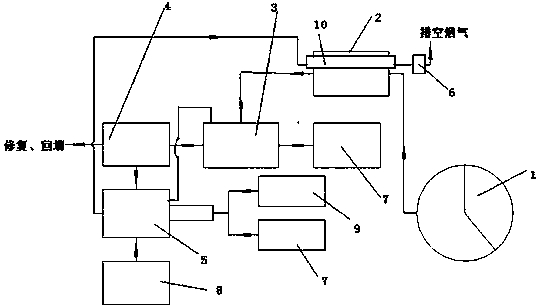

[0023] Example 1. If figure 1 As shown, a structure for in-situ restoration of a municipal solid waste landfill, which includes a screening device 1, the screening device 1 is connected to the garbage preheating furnace 2 through the feeding device I, and the garbage preheating furnace 2 is equipped with a replacement The heating device 10, the garbage preheating furnace 2 is connected with the layer combustion incineration equipment 3 through the feeding device II, and the layer combustion incineration equipment 3 is a mechanical grate furnace, a rotary kiln or a layer combustion pyrolysis furnace, and on the layer combustion incineration equipment 3 An air distribution system 7 is provided; a smoke outlet and a slag outlet are provided on the layer combustion incineration equipment 3, and the slag outlet is connected with the slag screening device 4, and the smoke outlet and the slag screening device 4 are connected to the secondary Combustion furnace 5 is connected, is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com